Large-diameter plane optical element defect three-dimensional fast dark field detection device and method

A technology for optical components and dark field detection, applied in the direction of optical testing flaws/defects, etc., can solve the problem of not being able to detect the depth information of defects, and achieve the effect of improving detection efficiency and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

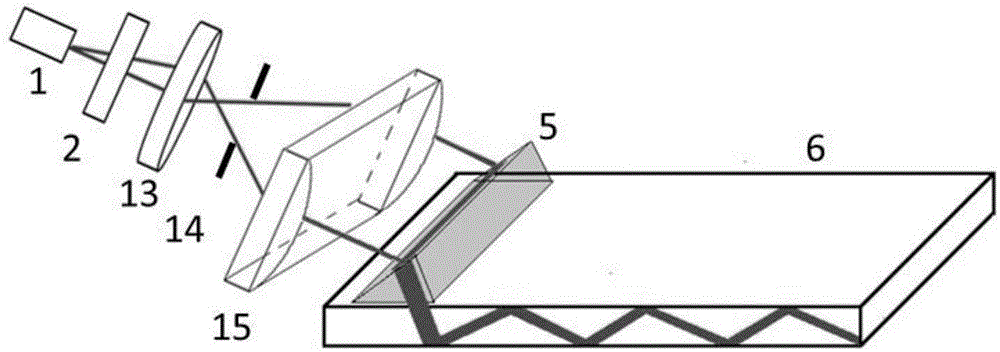

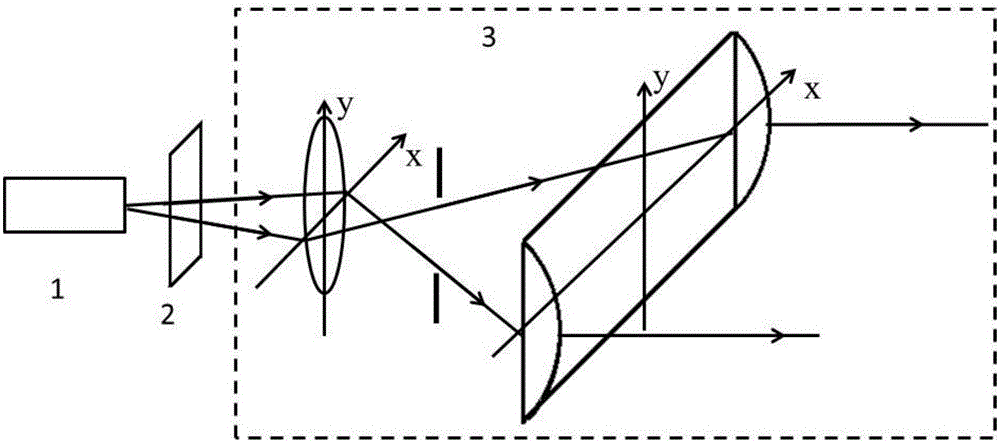

[0018] Such as figure 1 As shown, the three-dimensional rapid dark-field detection device for large-diameter planar optical elements of the present invention includes an illumination light source, a polarizer, a collimator lens system, a one-dimensional electronically controlled light source adjustment bracket, a right-angle prism, and a large-diameter planar optical element to be tested. 1. One-dimensional electronically controlled translation One-dimensional electronically controlled translational object platform, analyzer, imaging lens, CCD, computer, box. Among them, the lighting source, polarizer, and collimating lens system are arranged in sequence and installed on the one-dimensional electric light source adjustment bracket; On the electronically controlled transl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com