Particle diameter distribution online detecting device of granulating fluidized bed

A detection device, particle diameter technology, applied in the direction of measuring device, particle and sedimentation analysis, particle size analysis, etc., to achieve the effect of improving the detection environment, reducing the detection speed and the requirements of additional cleaning accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

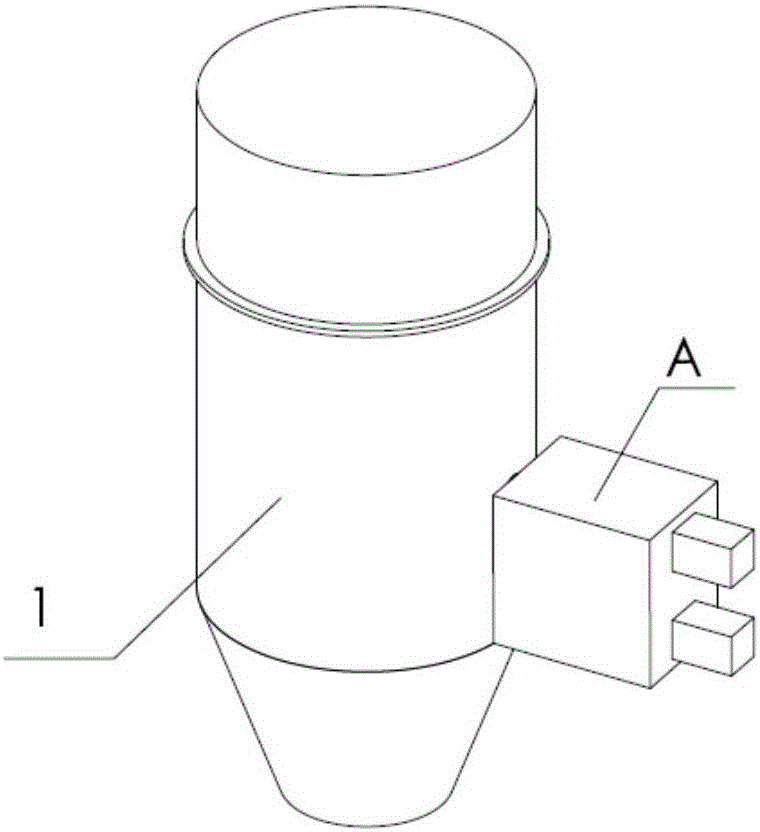

[0044] Such as figure 1 As shown, an online detection device for particle diameter distribution in a granulation fluidized bed, the detection device A is installed outside the fluidized bed reaction chamber 1; the detection device A has a sealed shell, and the seal between the shell B and the fluidized bed reaction chamber 1 connected, a sealed cavity is formed in the housing.

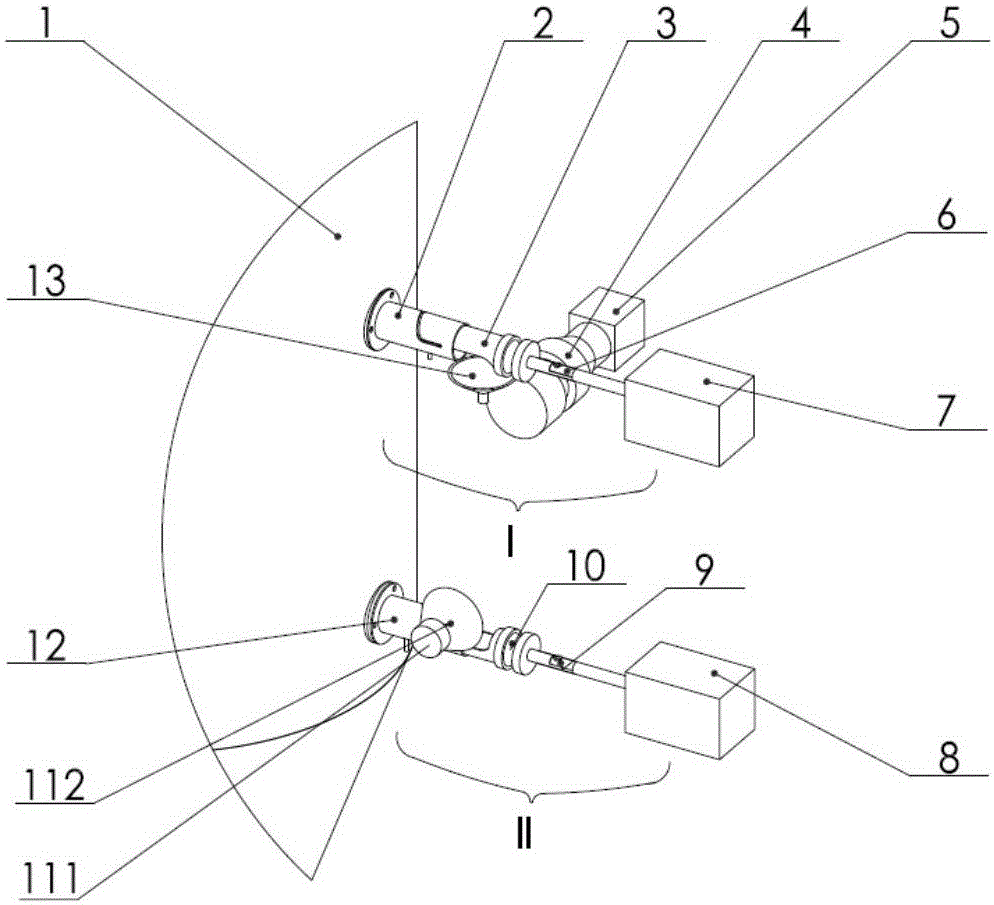

[0045] Such as figure 2 As shown, the casing of the detection device A is provided with a sampling mechanism 1 that can extend into the fluidized bed reaction chamber 1 to take out samples. When the sampling mechanism 1 extends into the fluidized bed reaction chamber 1, it is located at the sampling station. After the fluidized bed reaction chamber 1, the sample is located at the dispersing station when it falls, and the sampling mechanism I reciprocates between the sampling station and the dispersing station; the sampling mechanism 1 is sealed and matched with the chamber wall of the fluidized bed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com