Apparatus and method for testing in-situ triaxial tension fatigue under multi-field coupling

A fatigue test, in-situ technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of high precision and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

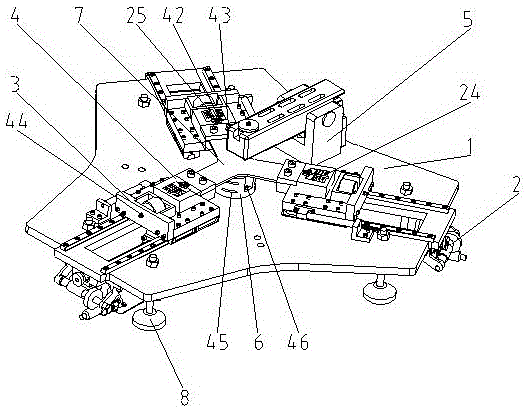

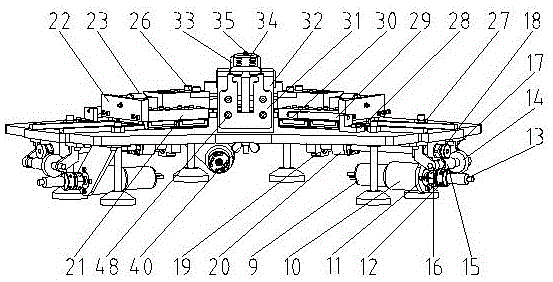

[0042] see Figure 1 to Figure 13 As shown, the multi-field coupling in-situ triaxial tensile fatigue testing device of the present invention includes triaxial tensile, fatigue loading and measurement subsystems, thermal field loading subsystems, and cantilever indentation loading and measurement subsystems;

[0043] The triaxial tension, fatigue loading and measurement subsystem includes: a main platform 1, a motor drive unit 2 for triaxial tension, an axial movement unit 3, a fatigue and fixture unit 4, an adjustable shock-absorbing foot cup 8, a connecting Platform 20, tension sensor 23, the main platform 1 is supported by six adjustable shock-absorbing foot cups 8, and placed on the shock-isolation platform as a whole, the height of the main platform 1 is guaranteed by the adjustment of the adjustable shock-ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com