Integrated waste heat recovery drying device

A waste heat recovery and drying device technology, applied in heating devices, drying, dryers and other directions, can solve the problems of great influence on energy consumption, exposed heaters, and large waste of heat dissipation of the casing, and achieves a wide range of applications, Space saving and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

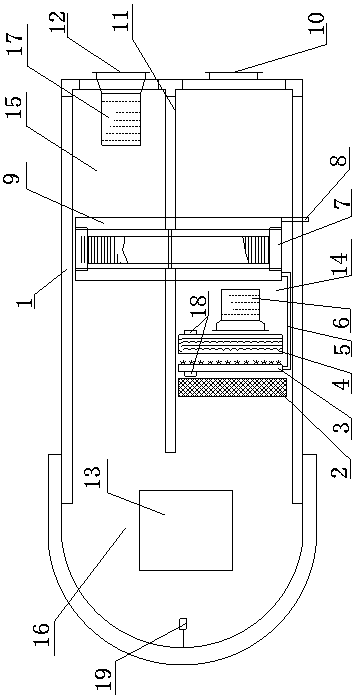

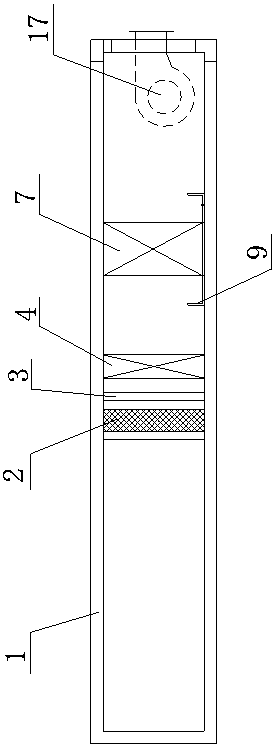

[0018] Such as figure 1 with figure 2 As shown, the integrated waste heat recovery drying device includes a box body 1, a middle partition 11 is arranged in the box body 1, a three-dimensional heat pipe 7 passing through the middle partition 11 and a condensed water pan 9 at the bottom of the three-dimensional heat pipe 7, One end of the middle partition 11 is fixed to the box body 1, and the other end is a free end. The two sides of the middle partition 11 are respectively a heating zone 14 and an exhaust area 15, and an oven is formed between the free end of the middle partition 11 and the box body 1. Dry zone 16, fresh air inlet 10 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com