Two-stage multi-sheet electromagnetic clutch

An electromagnetic clutch, multi-plate technology, used in magnetic drive clutches, clutches, non-mechanical drive clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

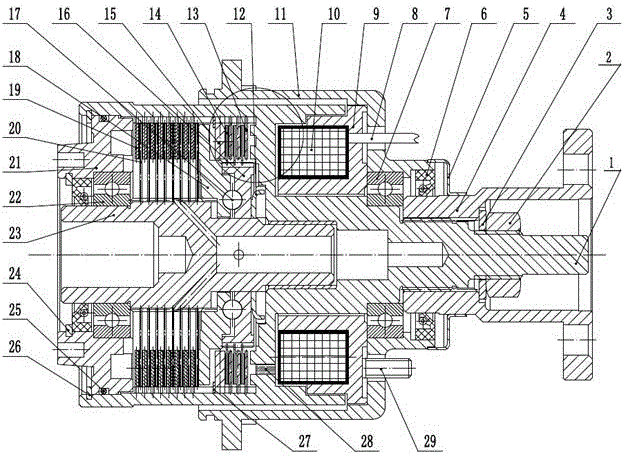

[0036] Embodiment 1: see figure 1 .

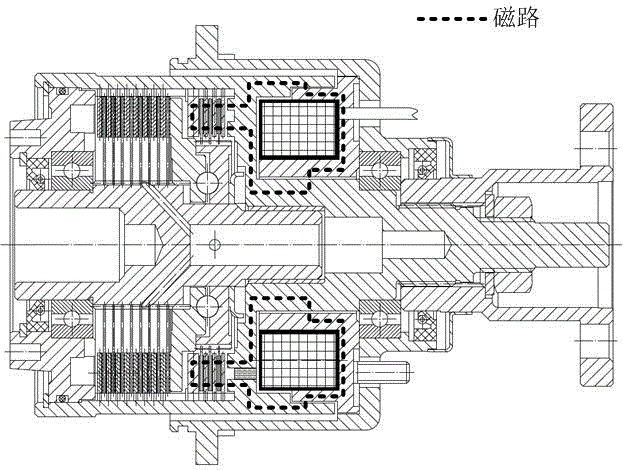

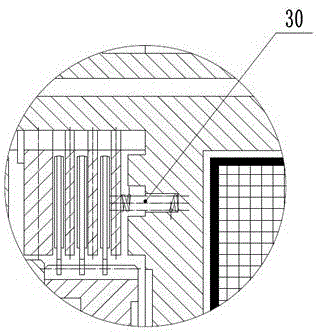

[0037] A two-stage multi-plate electromagnetic clutch. This device includes an input flange 4, which is splined with the input shaft 1 and fixed by a fastener 2. The input shaft 1 includes a traditional input shaft and The combined form of the traditional shell, and has the design of the magnetic passage. There is a magnetic isolation groove on the end surface of the input shaft close to the coil 10. The magnetic isolation groove is filled with non-magnetic materials, such as aluminum alloy, copper, etc., and the input shaft 1 passes through the input shaft. Bearing 7 is supported on housing 11, housing 11 is equipped with electromagnet assembly, electromagnet assembly includes coil 10 and iron core 9, electromagnet assembly is fixed on housing 11 by iron core bolt, the whole magnetic circuit includes iron core 9 , the input shaft 1 and the primary active friction plate 13, the primary driven friction plate 14 and the armature 15, the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com