U-shaped continuous deslagging equipment for vertical shaft

A U-shape, vertical shaft technology, applied in vertical shaft equipment, mining equipment, sinking, etc., can solve the problems of low slag discharge efficiency, non-continuous slag discharge, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

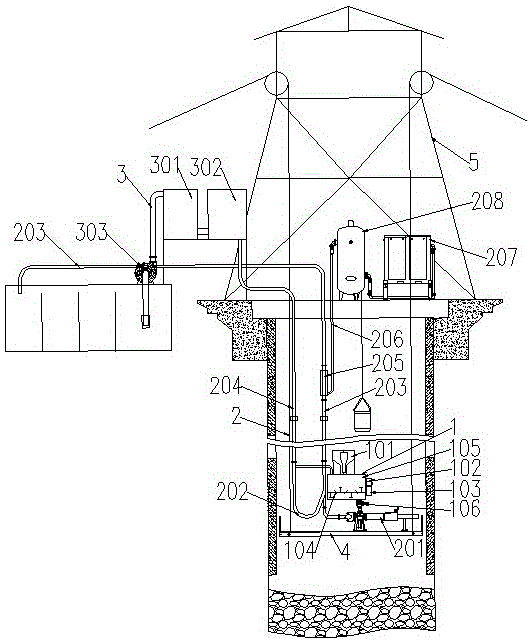

[0017] A U-shaped continuous slagging equipment for vertical shafts, such as figure 1 As shown, it includes a slag slurrying system 1 , a slag transportation system 2 , a mud separation system 3 , a bottom suspension pan 4 and a derrick 5 . Derrick 5 is fixed on the shaft upper end, and fixed pulley is fixed on the derrick 5, and bottom hanging plate 4 is suspended on upper derrick 5 by fixed pulley, and bottom hanging plate 4 is positioned at vertical shaft. The mud separation system 3 is arranged outside the shaft, and the wellhead of the shaft is provided with a sealing flat car. The slag slurrying system 1 is installed on the hanging pan 4 at the bottom of the shaft, the slurry outlet of the slag slurrying system 1 is connected to the slurry inlet of the slag transportation system 2, and the slurry outlet of the slag transportation system 2 is separated from the slurry The slurry inlet of the system 3 is connected, the slurry outlet of the slag transportation system 2 is ...

Embodiment 2

[0020] A U-shaped continuous slagging equipment for vertical shafts, such as figure 1 As shown, it includes a slag slurrying system 1 , a slag transportation system 2 , a mud separation system 3 , a bottom-hole suspension pan 4 and a derrick 5 , and the bottom-hole suspension pan 4 is suspended on the derrick 5 . The mud separation system 3 is arranged outside the vertical shaft, and the slag slurry system 1 is installed on the hanging pan 4 at the bottom of the shaft. The slurry outlet of the soil transportation system 2 is connected with the slurry inlet of the mud separation system 3, the slurry outlet of the muck transportation system 2 is connected with the muck pulping system 1, and the slurry outlet of the mud separation system 3 is connected with the muck The slurry inlet of the transport system 2 is connected.

[0021] The mud separation system 3 includes a mud separation station 301 , a mud tank 302 and a sedimentation tank 304 . The mud separation station 301, the...

Embodiment 3

[0024] A U-shaped continuous slagging equipment for vertical shafts, such as figure 1 As shown, it includes a slag slurrying system 1 , a slag transportation system 2 , a mud separation system 3 , a bottom-hole suspension pan 4 and a derrick 5 , and the bottom-hole suspension pan 4 is suspended on the derrick 5 . The mud separation system 3 is arranged outside the vertical shaft, and the slag slurry system 1 is installed on the hanging pan 4 at the bottom of the shaft. The slurry outlet of the soil transportation system 2 is connected with the slurry inlet of the mud separation system 3, the slurry outlet of the muck transportation system 2 is connected with the muck pulping system 1, and the slurry outlet of the mud separation system 3 is connected with the muck The slurry inlet of the transport system 2 is connected.

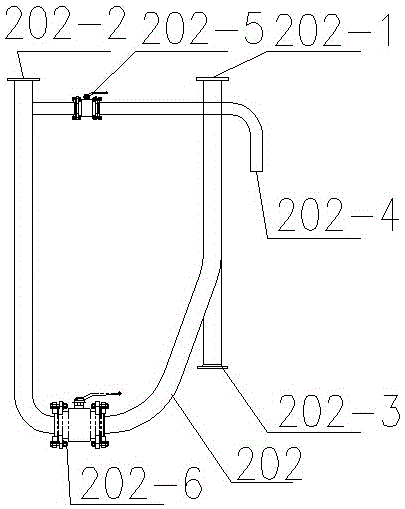

[0025] The muck transportation system 2 includes a grouting pump 201, a grout discharge pipe 203 and a grout inlet pipe 204, and the grout pump 201, the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com