Splash-proof joint of square drill rod

A technology of anti-splash joints and drill pipe joints, which is applied in the field of oil drilling valves, and can solve problems such as troublesome operation, high cost, and easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

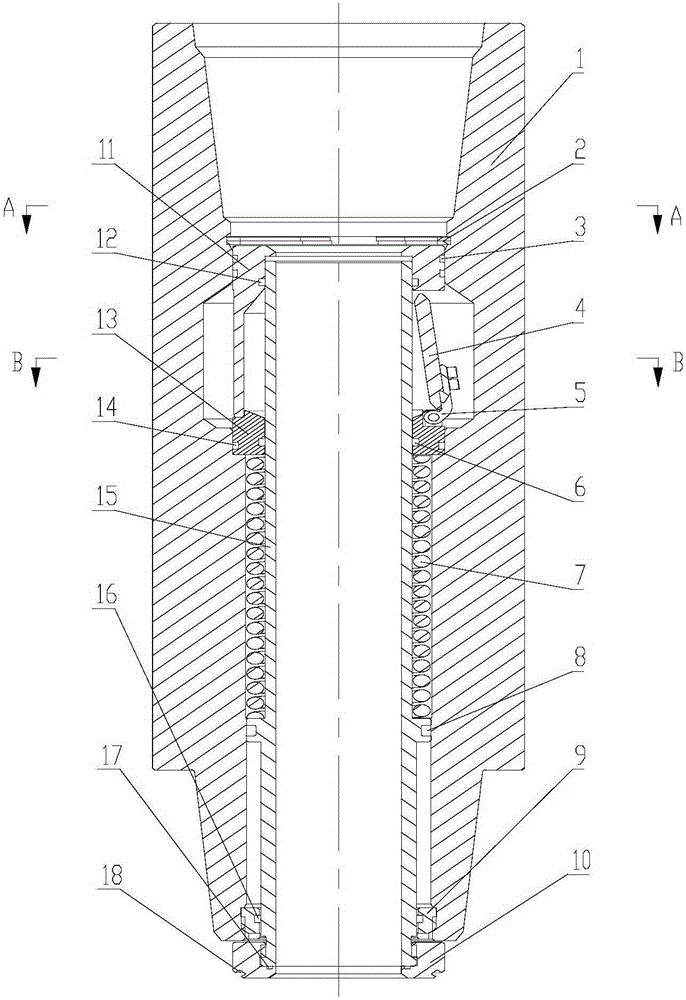

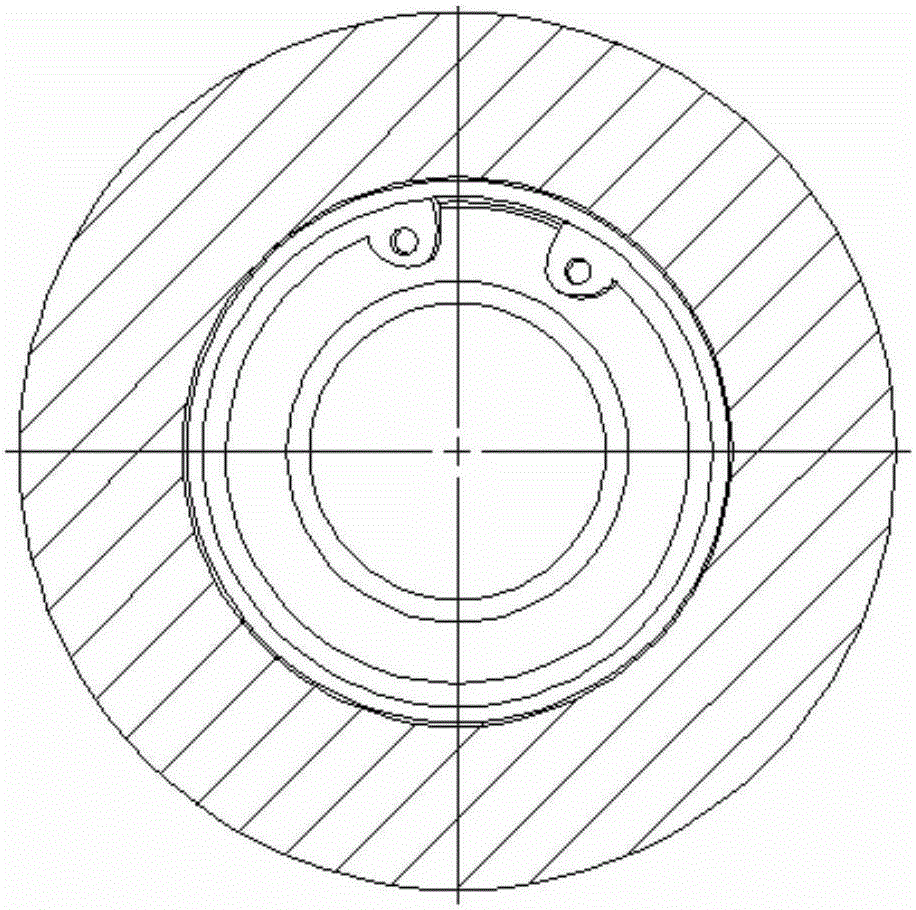

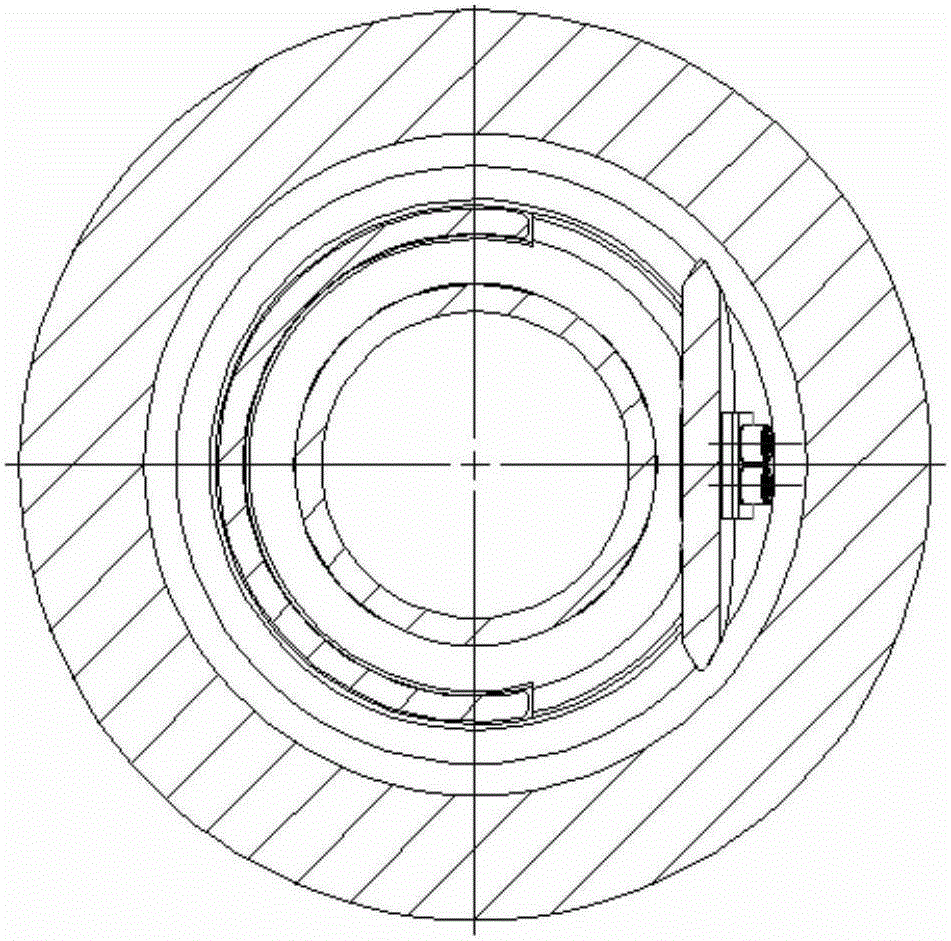

[0023] Such as Figure 1-3 As shown, the present invention provides a splash-proof joint for a kelly rod. The splash-proof joint is composed of a brake piston cylinder 15, a spring check valve plate 4, and an outer cylinder 1. Use the tightening and unloading of the thread of the outer cylinder and the lower drill rod to control the axial movement of the brake piston cylinder; use the position of the brake piston to control the switch of the spring check valve plate; the outer cylinder and the brake piston cylinder during drilling A sealed space is formed between them, so that the valve plate in the sealed space does not contact the mud environment; when the thread is removed, the brake piston cylinder releases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com