Detachable concrete component constructing method

A technology of concrete and concrete beams, which is applied to bridge parts, truss structures, joists, etc., can solve the problems that concrete components cannot be reused, and achieve the effects of reducing construction waste, small repair workload, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

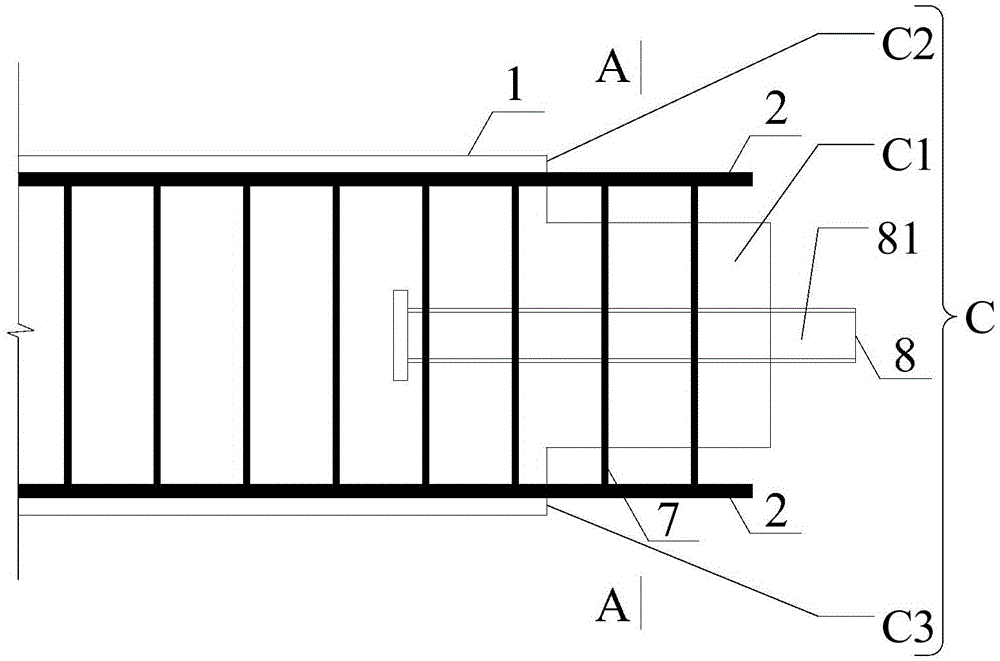

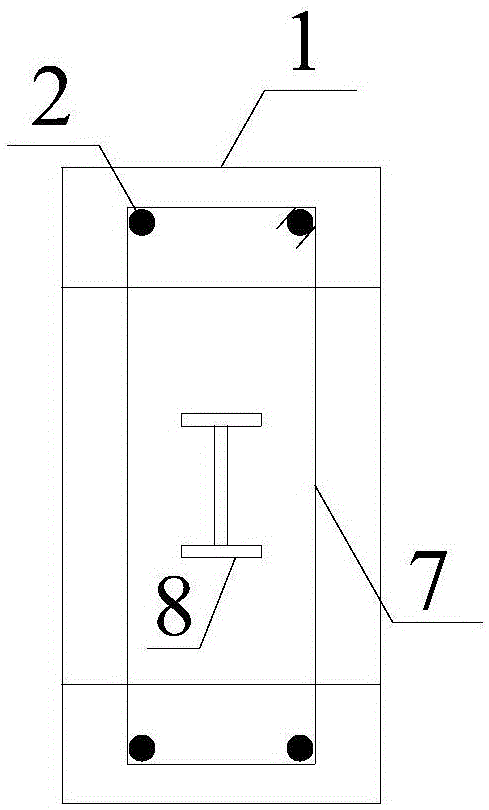

[0139] Use the following method to construct the detachable concrete components, first select and determine the first concrete beam section 1, such as figure 1 , 3 As shown, a plurality of first longitudinal bars 2 and first stirrups 7 are arranged on the upper and lower sides of the first concrete beam section 1 to form a reinforcement cage, and the first section steel 8 is pre-embedded inside the first concrete beam section 1 . One end of the first section steel 8 pre-embedded in the first concrete beam section 1 is provided with a steel plate for anchorage. Among them, it is necessary to ensure accurate component dimensions and accurate longitudinal reinforcement positions during construction, and the reinforcement and cross-sectional dimensions are determined by actual working conditions. The first section steel 8 is required to meet the local shear strength and have a certain degree of safety. The outer dimension B1 of the first stirrup 7 is determined by the first long...

Embodiment 2

[0163] The detachable concrete member made by the construction method in the above-mentioned embodiment 1 has the following structure.

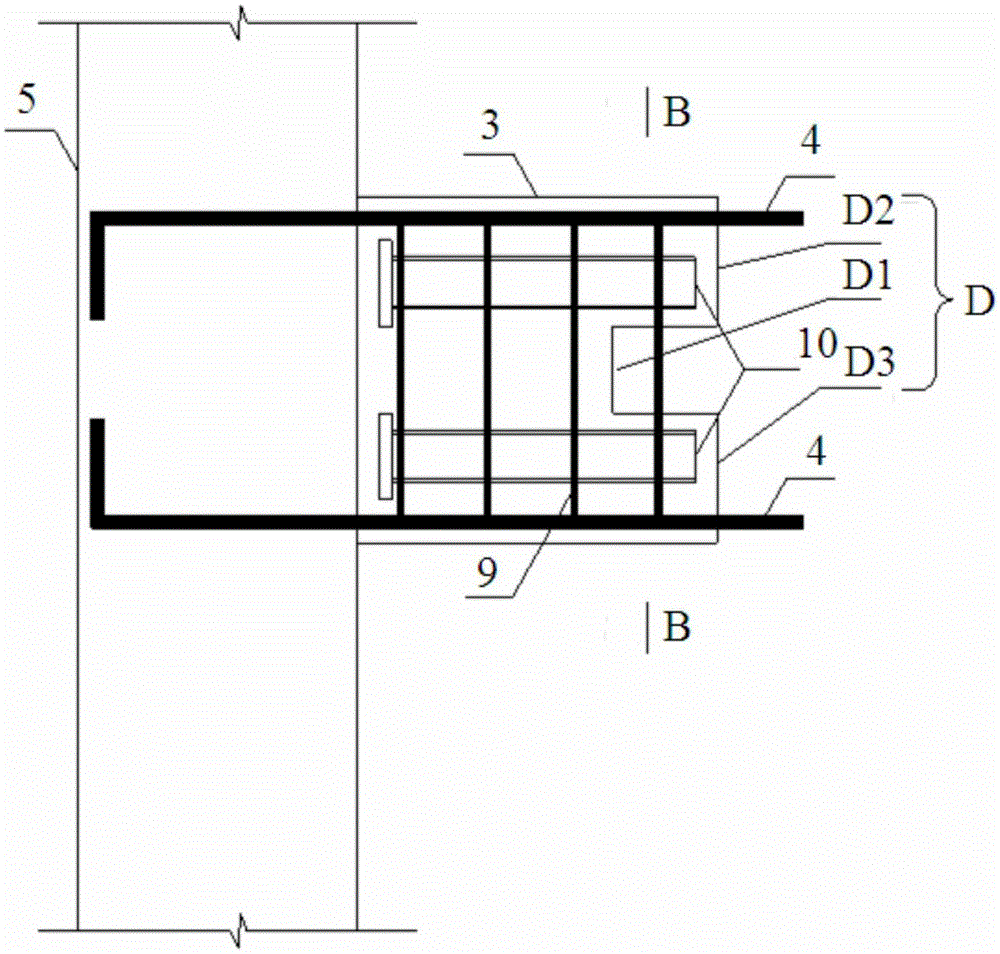

[0164] The detachable concrete member includes a concrete frame column section 5 , a first concrete beam section 1 , a second concrete beam section 3 , and a longitudinal bar intersection area 6 .

[0165] Among them, such as figure 1 As shown, one end of the first concrete beam segment 1 is provided with a male tenon C. The common tenon C includes a tenon C1, an upper tenon shoulder C2 and a lower tenon shoulder C3. The upper tenon shoulder C2 is aligned with the lower tenon shoulder C3 and the tenon C1 is opposite to the upper tenon shoulder. The tenon shoulder C2 and the lower tenon shoulder C3 protrude outwards, and a plurality of first longitudinal ribs 2 are respectively arranged on the upper and lower sides of the first concrete beam section 1, and one end of the first longitudinal ribs 2 runs through the upper tenon shoulder C2 and th...

Embodiment 3

[0172] The detachable concrete member in the embodiment 2 that the construction method in the embodiment 1 is made is carried out relevant performance test, meanwhile, the monolithic concrete member that adopts at present conventionally of the same size is carried out relevant performance test, both relevant performance test results See Table 1. In addition, the detachable concrete components were disassembled and the concrete components after secondary splicing were tested for related performance. The test results are shown in Table 1.

[0173] Table 1 Performance index comparison

[0174]

[0175] It can be seen from Table 1 that the overall flexural bearing capacity and overall shear bearing capacity of the detachable concrete beam of the present invention are similar to those of the monolithic concrete member, and the bearing capacity after disassembly and secondary splicing is still consistent with it. The local shear bearing capacity of the detachable concrete beam o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com