Non-powered automatic water down one-piece toilet

A technology for automatic flushing and toileting, applied in flushing toilets, water supply devices, flushing equipment with water tanks, etc., can solve problems such as increased operating time, decreased transfer efficiency, water waste, etc., to ensure the time to discard toilet paper, The effect of delaying the drive time and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

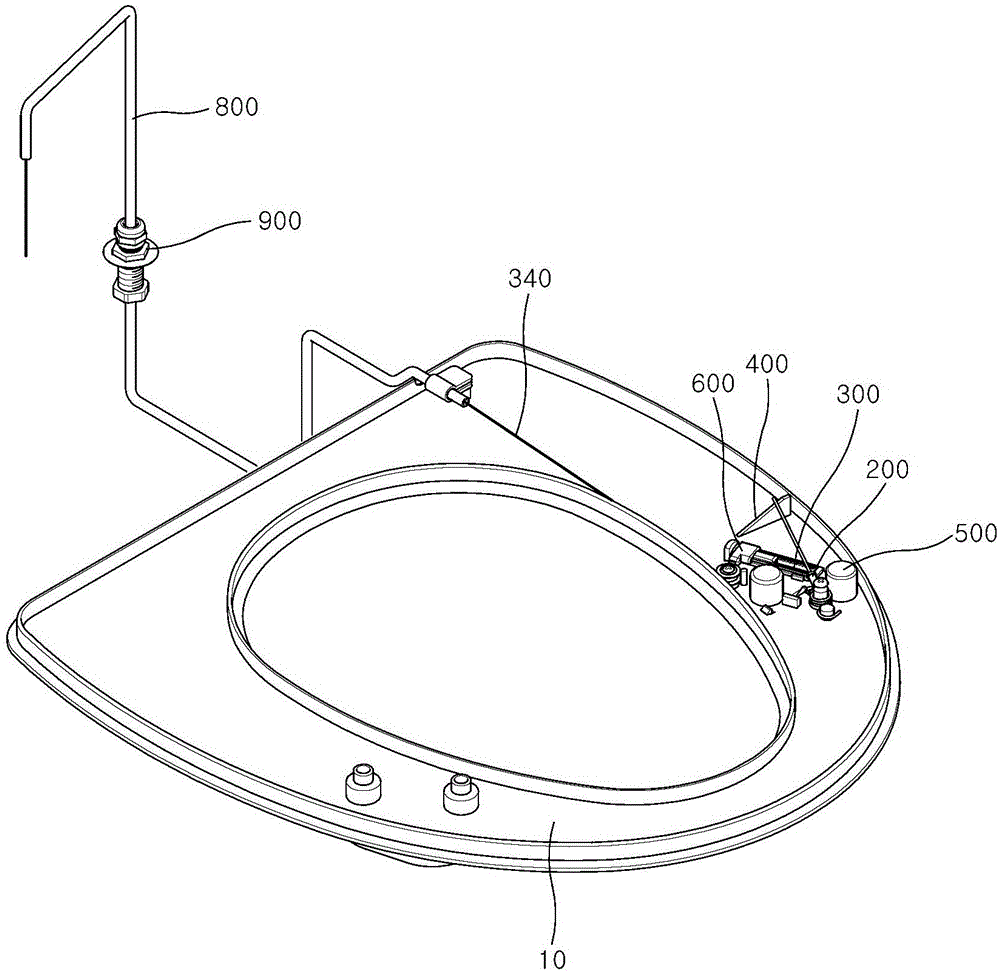

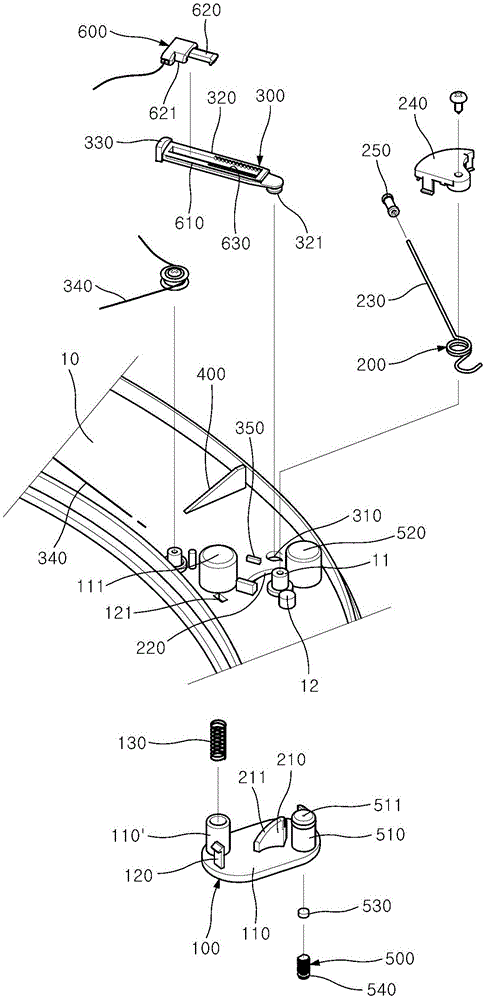

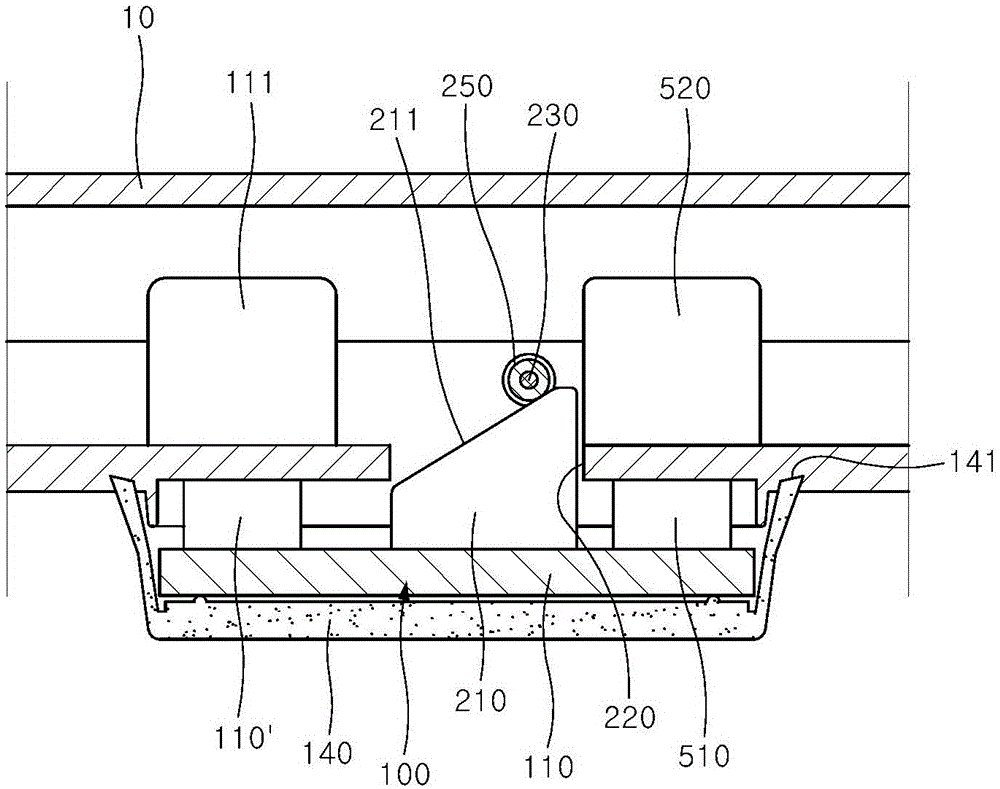

[0050] Hereinafter, the present invention will be described in detail with reference to the drawings. figure 1 A perspective view representing the present invention, figure 2 Representing an exploded perspective view of the present invention, Figure 3 to Figure 4 A sectional view showing the present invention.

[0051] According to one aspect of the present invention, a toilet integrated with automatic drainage without power supply is configured as follows. Including: setting hole 700, formed in a through manner, so that the toilet pad 10 is installed on the top of the toilet body 20, and the lead wire guide part 800 is combined with the water tank 21 provided at the rear end of the toilet body 20; the lead wire guide part 800, one end is fixed on the toilet pad 10, and the other end is placed inside the water tank 21 through the setting hole 700 to guide the operation of the sewer lead wire 340; the anti-leakage part 900 prevents the lead wire combined with the setting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com