Burnup saving type engine oil composition

A composition and engine oil technology, which is applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of increased evaporation loss and increased wear of engine oil, and achieve less evaporation loss, good low-temperature viscosity characteristics, and good fuel economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, the present invention will be specifically described through examples.

[0054] As the mineral oil base oil, the kinematic viscosity at 100°C obtained by hydrodewaxing the product oil obtained by the hydrocracking of heavy oil is 4.3 mm. 2 / s base oil.

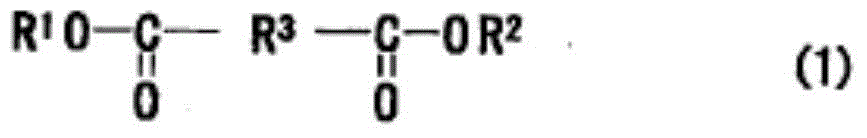

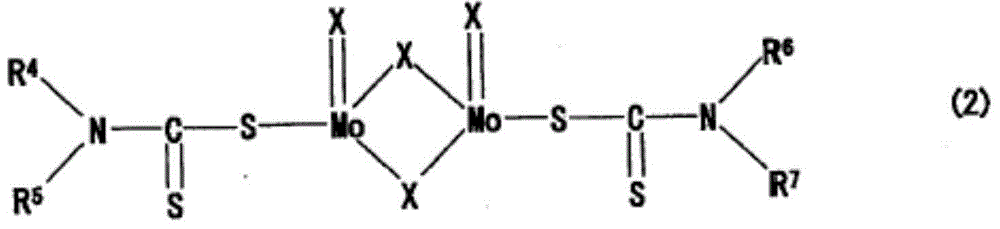

[0055] As a dicarboxylic acid diester having a molecular weight of 400 to 450 represented by the general formula (1) (hereinafter referred to as the diester of the present invention), the kinematic viscosity at 100°C is 3.2mm 2 / s, dioctyl sebacate with a molecular weight of 426.

[0056] In addition, as a comparative diester that does not satisfy the diester of the present invention, a kinematic viscosity at 100°C of 3.6 mm was used. 2 / s, diisodecyl adipate with a molecular weight of 426, the kinematic viscosity at 100°C is 2.3mm 2 / s, dioctyl adipate with a molecular weight of 370 and a kinematic viscosity of 3.4mm at 100°C 2 / s of trimethylolpropane (TMP) enanthate.

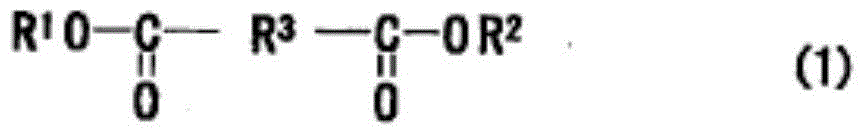

[0057] As additives, the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com