A kind of high salinity desert sand fixing agent

A technology of sand-fixing agent and desert land, which is applied in the direction of organic fertilizer, fertilizer mixture, climate change adaptation, etc. It can solve the problems of high salinity and alkali resistance, easy pulverization of sand-fixing materials, etc., to achieve easy operation, reduce construction cost, and speed up the ecological process. Recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve polyether L35 in water and prepare solutions with different mass fractions for later use. The method is to prepare 10 parts of polyether L35 solution, 3 parts of anionic polyvinyl acetate copolymer emulsion, After mixing evenly, it is evenly sprayed on the surface of sandy soil with a salt content of 3%, and after the mixture is naturally air-dried, a consolidated layer with good pressure bearing and excellent wind erosion resistance is formed.

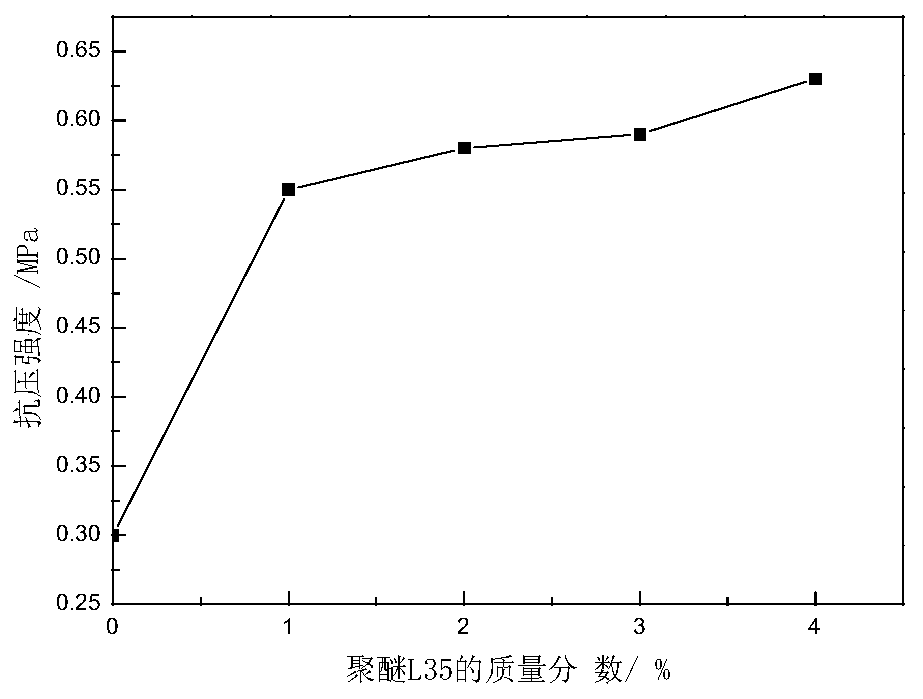

[0031] Preparation of sand mold: Dissolve polyether L35 in water to make solutions with mass fractions of 0.5%, 1.0%, 2.0%, 3.0%, and 4.0%, and then use the above polyether L35 solution to anionic polyvinyl acetate copolymer emulsion Diluted to a diluent with a solid content of 3%; take 10g of sand with a salt content of 3% and mix it with 1.0g of the above diluent to prepare a sand mold (2.0cm in diameter and 2.2cm in height), and dry under natural conditions. Get the sand mold.

[0032] figure 1 It shows the crysta...

Embodiment 2

[0038] The alkylphenol polyoxyethylene ether is dissolved in water and prepared into solutions with different mass fractions for later use. The method is to prepare 8 parts of the alkylphenol polyoxyethylene ether solution, non-ionic polyoxyethylene (Vinyl acetate-ethylene) copolymer emulsion 5 parts, after mixing evenly, spray it evenly on the sandy soil surface with a salt content of 3%, and after the mixture is naturally air-dried, a layer with good pressure resistance and excellent wind erosion resistance is formed The consolidation layer of the effect.

Embodiment 3

[0040] The fatty alcohol polyoxyethylene ether is dissolved in water and prepared into solutions with different mass fractions for later use. The method is prepared by 15 parts of fatty alcohol polyoxyethylene ether solution, nonionic poly(acetic acid 4 parts of vinyl ester-ethylene) copolymer emulsion, after mixing evenly, spray it evenly on the sandy soil surface with a salt content of about 3%, and form a layer after the mixture is naturally air-dried, which has good pressure bearing and excellent wind erosion resistance effect the consolidation layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com