Method for preparing salt-tolerance monascus pigment

A technology of monascus pigment and salt tolerance, which is applied in the field of preparation of salt tolerance monascus pigment, can solve problems such as poor salt tolerance, and achieve the effects of improving application adaptability, solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

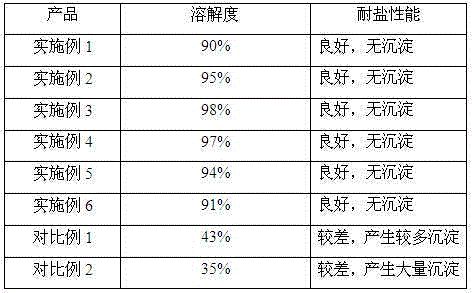

Examples

Embodiment 1

[0031] The preparation method of a kind of salt-tolerant monascus pigment of the present embodiment comprises the following steps:

[0032] S1. Stir and react 10 parts of Monascus pigment, 40 parts of ethanol, 60 parts of water, and 2 parts of sodium hydroxide at a temperature of 40°C for 1 hour, and let stand for 0.5 hours after the reaction;

[0033] S2. Add 25 parts of Tween-20 emulsifier to the product obtained in step S1 to carry out emulsification reaction, react at a rotating speed of 1500r / min for 0.5h, make the combination of emulsifier and monascus pigment stable, and let stand for 20min after the reaction;

[0034] S3. Add 20 parts of stabilizer propylene glycol to the product obtained in step S2 for high-pressure homogenization treatment at a temperature of 30°C for 20 minutes; then concentrate and separate ethanol and water at a temperature of 40~60°C and a vacuum of -0.08~ -0.095MPa, the Brix is 20~40Bx; and then spray-dried at a temperature of 70~100°C to obta...

Embodiment 2

[0036] The preparation method of a kind of salt-tolerant monascus pigment of the present embodiment comprises the following steps:

[0037] S1. Stir and react 10 parts of Monascus pigment, 50 parts of ethanol, 50 parts of water, and 3 parts of sodium hydroxide at a temperature of 45°C for 80 minutes, and let stand for 0.5 hours after the reaction;

[0038] S2. Add 30 parts of Tween-60 emulsifier to the product obtained in step S1 to carry out emulsification reaction, react at a rotating speed of 2000r / min for 0.5h, make the combination of emulsifier and monascus pigment stable, and let stand for 20min after the reaction;

[0039] S3. Add 25 parts of stabilizer propylene glycol to the product obtained in step S2 for high-pressure homogenization treatment at a temperature of 40°C for 15 minutes; then concentrate and separate ethanol and water at a temperature of 40~60°C and a vacuum of -0.08~ -0.095MPa, the Brix is 20~40Bx; and then spray-dried at a temperature of 70~100°C to ...

Embodiment 3

[0041] The preparation method of a kind of salt-tolerant monascus pigment of the present embodiment comprises the following steps:

[0042] S1. Stir and react 15 parts of Monascus pigment, 60 parts of ethanol, 60 parts of water, and 4 parts of sodium hydroxide at a temperature of 45°C for 120 minutes, and let stand for 0.5 hours after the reaction;

[0043] S2. Add 40 parts of Tween-80 emulsifier to the product obtained in step S1 to carry out emulsification reaction, react at a rotating speed of 3000r / min for 40min, make the combination of emulsifier and monascus pigment stable, and let stand for 20min after the reaction;

[0044] S3. Add 30 parts of stabilizer glycerin to the product obtained in step S2 for high-pressure homogenization treatment at a temperature of 35°C for 30 minutes; then concentrate and separate ethanol and water at a temperature of 40-60°C and a vacuum of - 0.08~-0.095MPa, brix 20~40Bx; then spray drying at 70~100°C to obtain a salt-tolerant monascus pig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com