Preparation and Application of Magnetic Nanoring Microwave Absorber

A technology of microwave absorber and magnetic nano ring, which is applied in the direction of nanotechnology, nanotechnology, low-dimensional magnetic materials, etc., can solve the problem that the diameter of the ring is not easy to control, and achieve the effect of easy industrial application and promotion, uniform particles and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

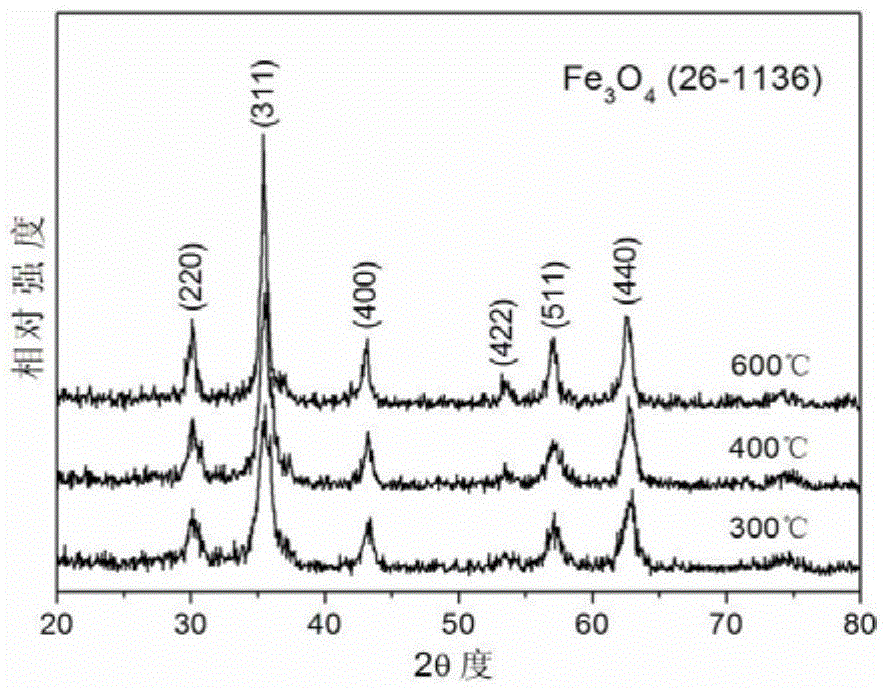

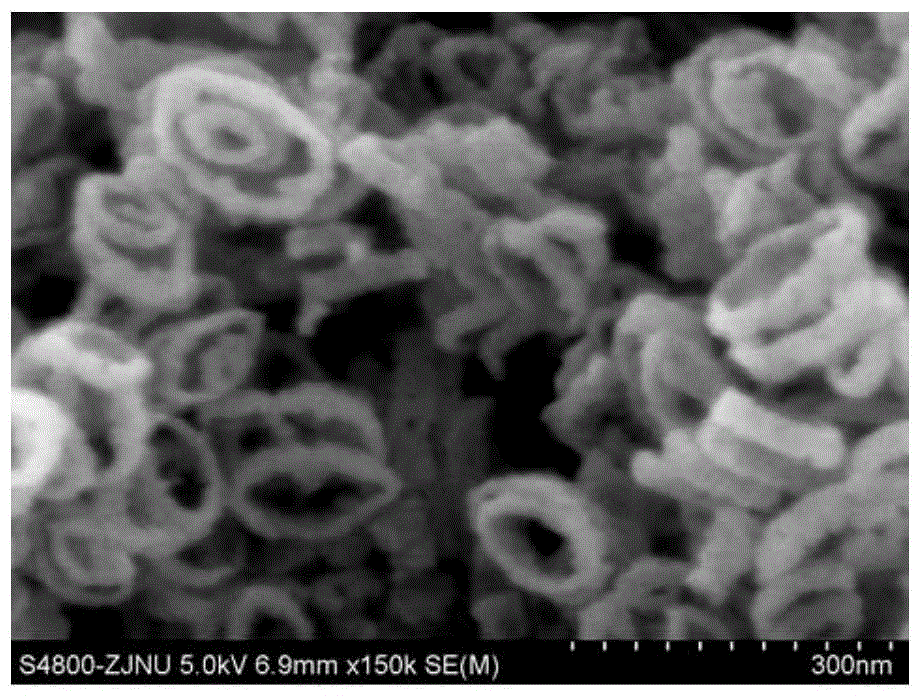

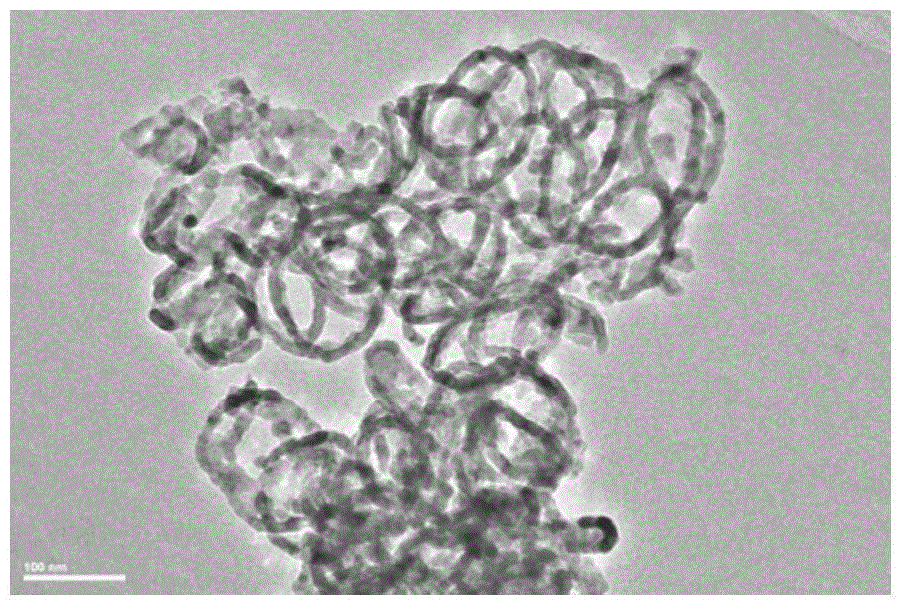

[0042] Load 0.4 grams of shuttle-shaped iron glycolate nanosheets [patent 201510175533.8] with a major axis length of 165-186 nm in a ceramic ark of 6 cm × 3 cm × 1.5 cm, place it in a single-temperature tube furnace, and heat it at 400 °C under nitrogen protection. °C for 2 hours (heating time is 1 hour). After the reaction was completed, it was cooled to room temperature with the furnace under the protection of nitrogen. The phase of the obtained product, the morphology, structure and selected area electron diffraction pattern observed under the scanning electron microscope and transmission electron microscope are as follows Figure 1 to Figure 4 As shown, it can be seen that the product is elliptical Fe 3 o 4 Polycrystalline nanoring microwave absorbers. The structural parameters and static magnetic properties test results of the product are shown in Table 1.

Embodiment 2

[0044] The steps are the same as in Example 1, but the reaction temperature is 300°C. The phase of the obtained product and the morphology observed under the scanning electron microscope are as follows: figure 1 , Figure 5 As shown, it can be seen that the product is elliptical Fe 3 o 4 Nano ring microwave absorber. The structural parameters and static magnetic properties test results of the product are shown in Table 1.

Embodiment 3

[0046] The steps are the same as in Example 1, but the reaction temperature is 600°C. The phase of the obtained product and the morphology observed under the scanning electron microscope are as follows: figure 1 , Image 6 As shown, it can be seen that the product is elliptical Fe 3 o 4 Nano ring microwave absorber. The structural parameters and static magnetic properties test results of the product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com