Lifting-force-reinforced wing section based on Magnus principle

An airfoil and lift technology, which is applied in the fields of aerospace and ship engineering, can solve the problems that cannot be solved, such as the increase of airfoil resistance, and achieve the effects of enhancing lift, reducing eddy current, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

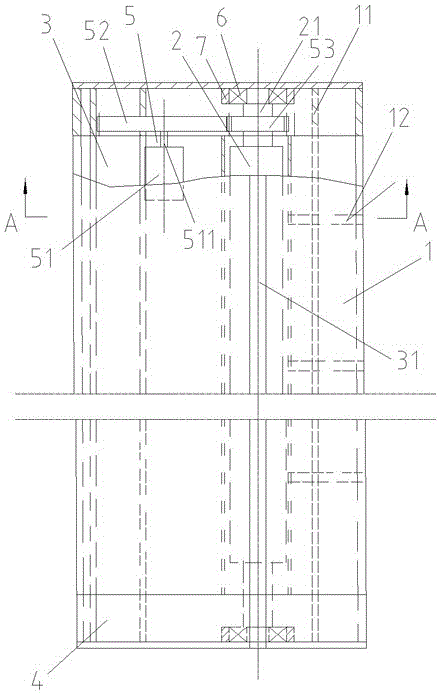

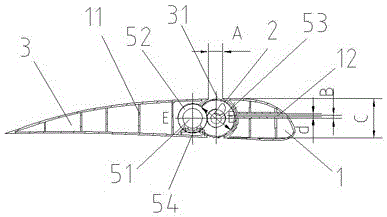

[0018] Such as figure 1 and figure 2 As shown, the present invention includes a front wing body 1, a Magnus cylinder 2 and a tail wing body 3, and the longitudinal ends of the front wing body 1 and the tail wing body 3 are vertically fixedly connected to the sealing body 4 respectively A lift-enhancing airfoil with a streamlined cross-section, a Magnus cylinder 2 is embedded between the front wing body 1 and the rear wing body 3, and the front wing body 1 and the rear wing body 3 The part adjacent to the Magnus cylinder 2 is concaved into an arc shape matching the Magnus cylinder 2 . Both the front wing body 1 and the tail wing body 3 are closed shells, and several rows of longitudinal ribs with different heights are respectively arranged at intervals in the shell of the front wing body 1 and in the shell of the tail wing body 3 plate 11 to improve the structural s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com