Making a baler for cotton straw bales that handle high-moisture content sludge and freshly filled soil

A technology of cotton straw and high moisture content is applied in the field of soil filling and sludge treatment, which can solve the problems of low efficiency and high labor intensity, and achieve the effect of reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

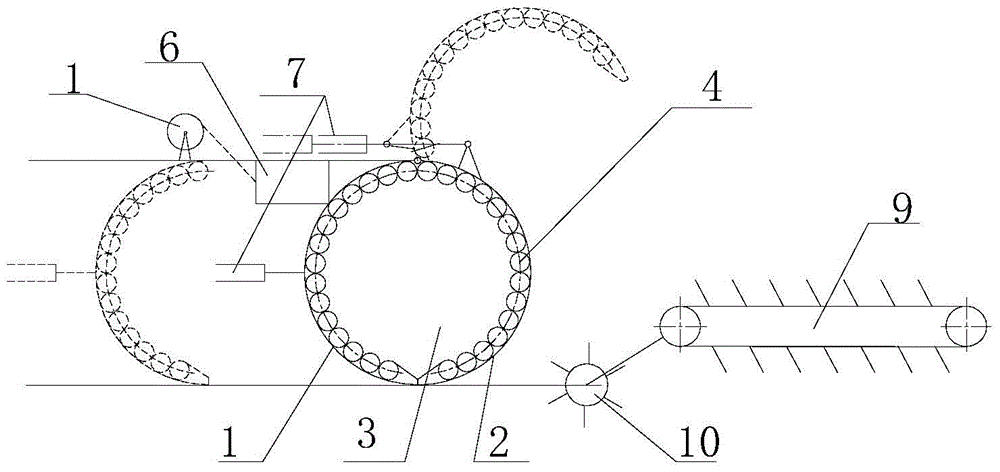

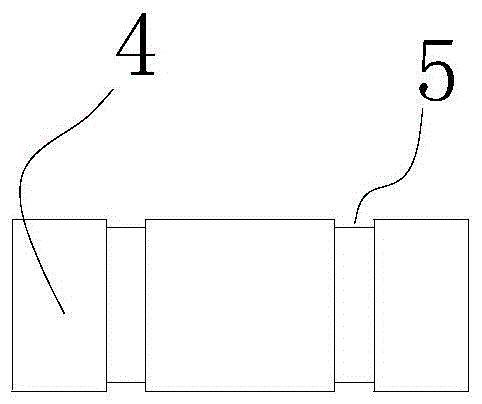

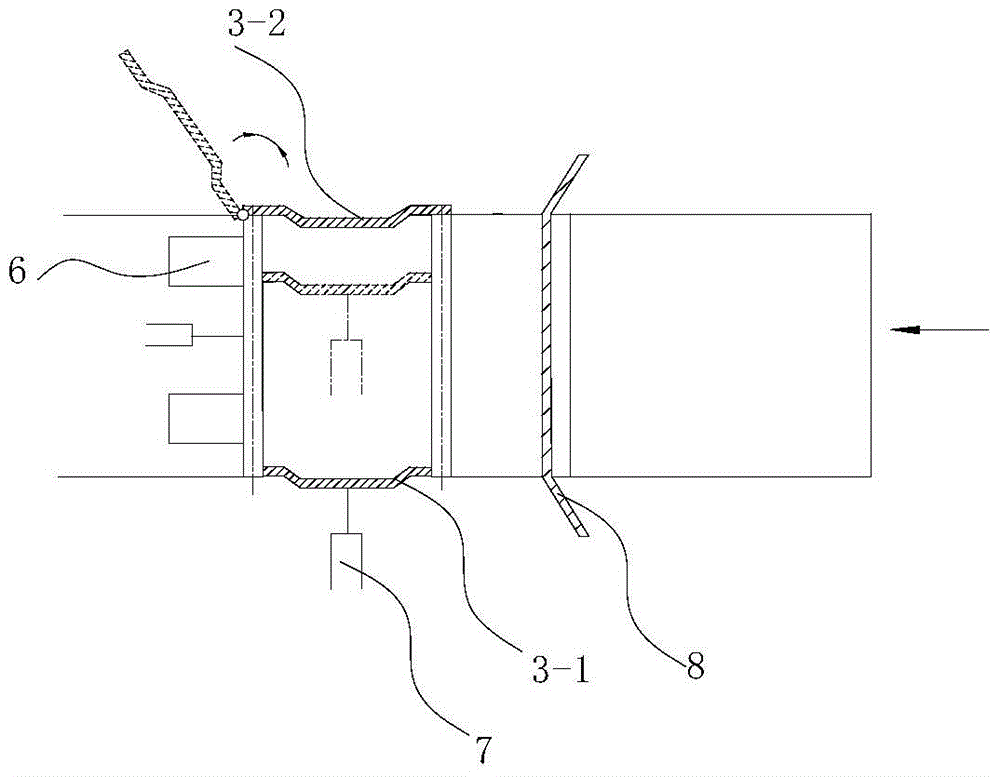

[0024] The strapping machine of this embodiment is as Figure 1-3 As shown, it includes a feeding mechanism, a baling chamber and a binding mechanism; the baling chamber includes a left half-mold 1 and a right half-mold 2, and the left half-mold 1 and the right half-mold 2 can be combined to form a cylindrical straw bale. Zone 3, the left half mold 1 can reciprocate laterally and horizontally to squeeze the cotton straw in the straw bale forming zone 3, and the right half mold 2 can be rotated and opened so that the feeding mechanism 6 can send the cotton straw into the extrusion straw bale forming zone 3. That is, the right half-mold 2 is used as a feed inlet after being rotated and opened; the inner surfaces of the left half-mold 1 and the right half-mold 2 are equipped with a number of rolls 4, and the rolls 4 are in the shape of a round shaft, and each roll 4 is circumferentially opened. There are two annular grooves 5, and the grooves 5 are located at both ends of the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com