An electronic voltage regulating electric furnace transformer

A technology of electric furnace transformer and electronic voltage regulation, which is applied in the direction of conversion equipment for intermediate conversion to DC, conversion equipment for conversion to DC without intermediate conversion, etc., which can solve the problem of difficult control of output voltage quality and large number of taps, etc. problems, to achieve the effect of improving realizability, improving production quality and reducing loop current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

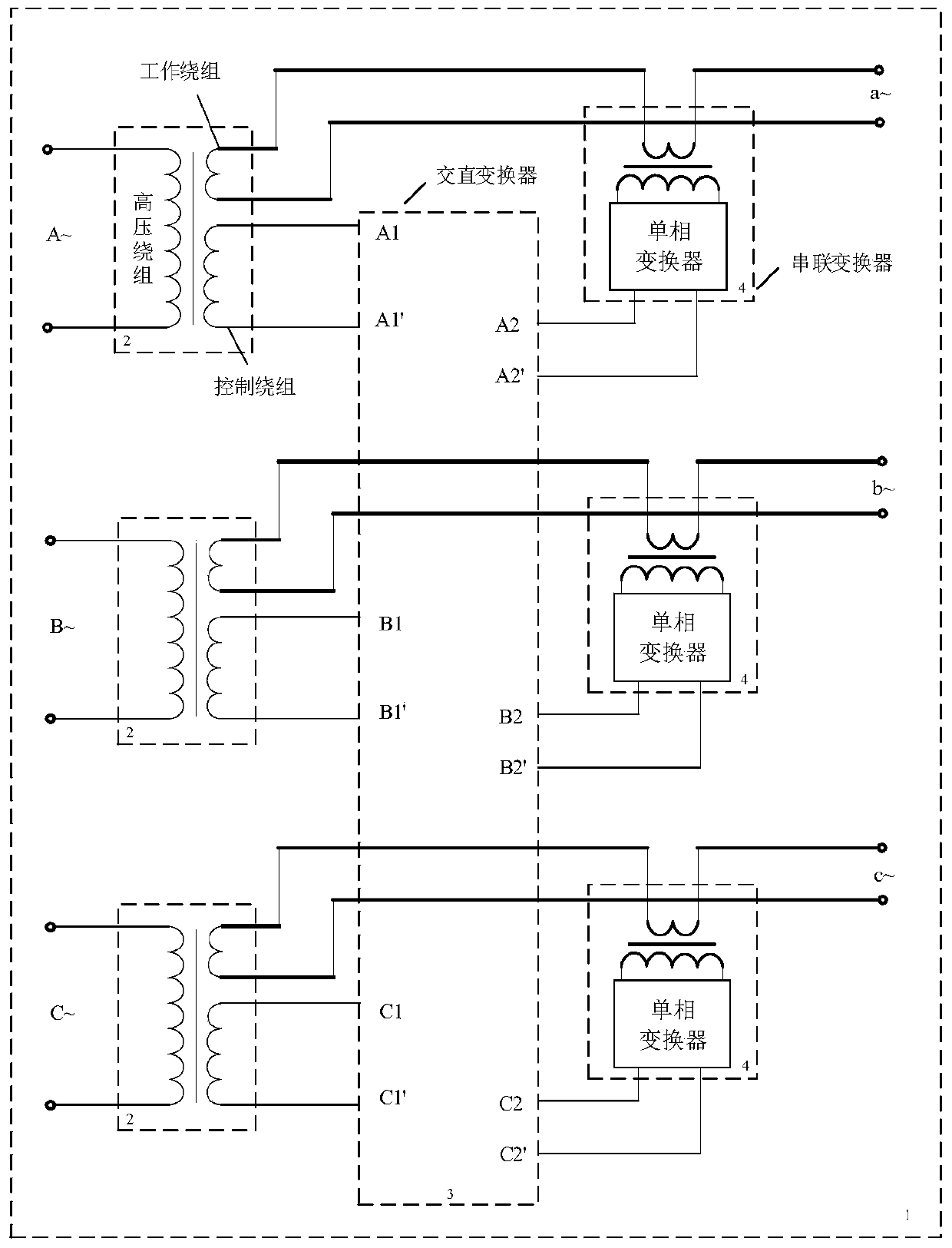

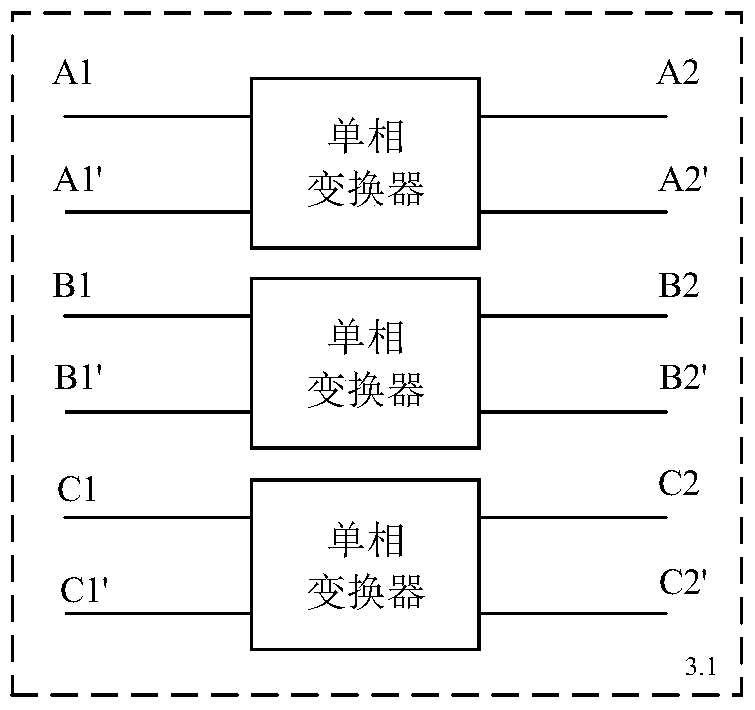

[0071] The system connection relationship of embodiment 1 is as Figure 8 As shown, the scheme of using a three-winding transformer to increase the coarse voltage regulation function; in this embodiment, the electronic voltage-regulating electric furnace transformer (1) is a three-phase structure, consisting of three three-winding voltage-regulating transformers (6), and three converters (4 ) and 1 AC-DC converter (3); 3 three-winding voltage-regulating transformers belonging to the ABC three-phase, the primary side is connected to the phase power supply, and the control winding is connected to the DC side of the phase converter through the AC-DC converter. The working winding supplies power to the electric furnace through the AC side of the phase converter.

[0072] In Example 1, the three-winding transformer adopts flux-changing voltage regulation, and a voltage-regulating winding is separately provided on the primary side; specifically, the primary side of the three-winding...

Embodiment 2

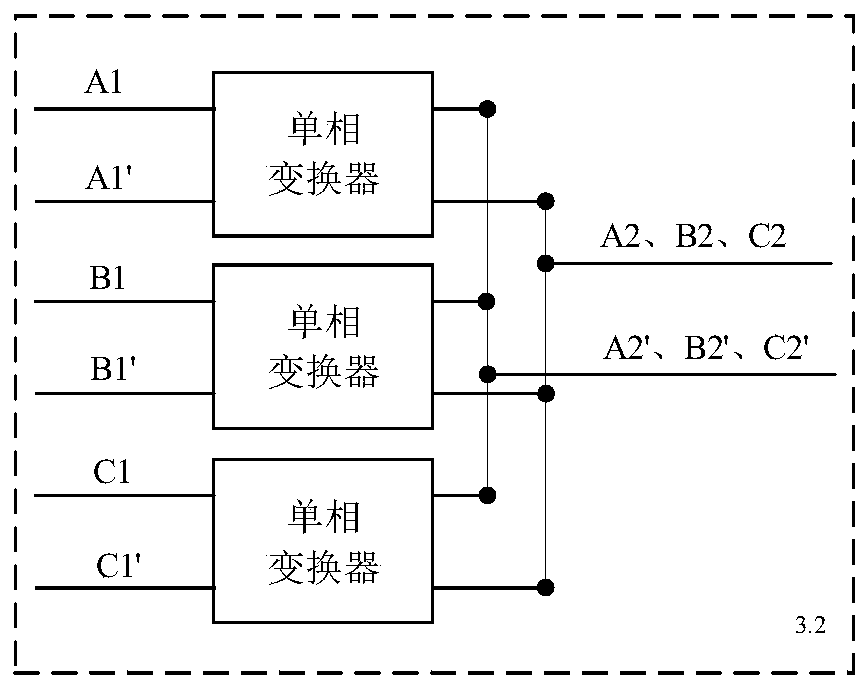

[0077] The system connection relation of embodiment 2 is as Figure 9 As shown, the scheme of "increasing parallel converters" is adopted; in this embodiment, the electronic voltage regulating electric furnace transformer (1) is a three-phase structure, consisting of three three-winding transformers (2), one AC-DC converter (3), It is composed of 3 series converters (4) and 3 parallel converters (5); it belongs to ABC three-phase three-winding transformer, its high-voltage winding is connected to the power supply of this phase, and its control winding is connected in series with this phase through the AC-DC converter The converter is connected to the DC side of the parallel converter, and its working winding supplies power to the electric furnace through the AC side of the series converter and the AC side of the parallel converter.

[0078] Its three-winding transformer is composed of high-voltage winding, working winding, control winding and other body structures of the three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com