Low-power sine wave motor

A sine wave, low power technology, applied in the field of sine wave motors, can solve the problems of increased after-sales service costs, affecting the performance of the motor, easy to generate high temperature, etc., to achieve good operating efficiency, large torque, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

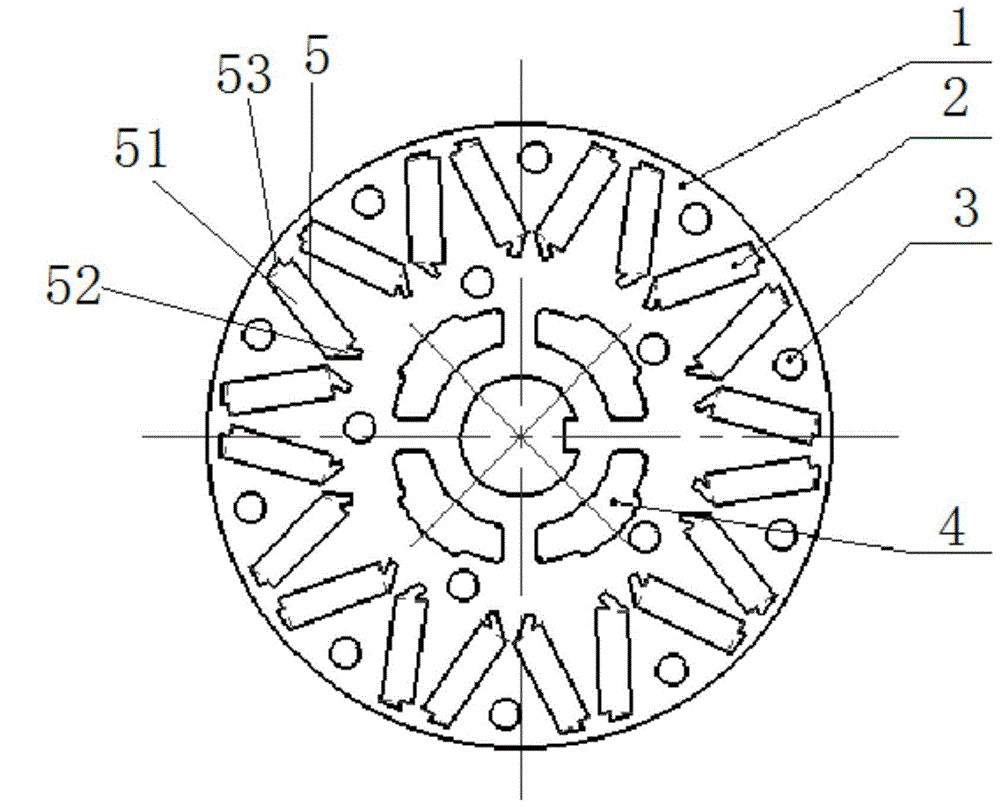

[0019] A small power sine wave motor, such as figure 1 As shown, it includes a housing and a Hall circuit board. The rotor (1) and the stator that cooperate with each other are arranged in the housing, and the rotor (1) is sequentially provided with a counterweight groove and a magnetic steel insertion groove (5) from the inside to the outside. , the counterweight slot and the magnetic steel slot (5) are arranged along the circumference of the rotor (1); the counterweight (4) is arranged in the counterweight slot, and the magnetic steel slot (5) is embedded There is a magnetic steel (3); the Hall circuit board is provided with a through hole for the rotating shaft, and the Hall circuit board is arranged on the inner surface of the housing, and the rotating shaft of the rotor (1) passes through the hole of the Hall circuit board Shaft through hole.

[0020] The magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com