Method for preparing graphene-based nickel oxide nanocomposite

A nanocomposite material, graphene-based technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of toxic organic solvents, high-level charge density, unfriendly environment, etc., to achieve load The effect of high quantity, uniform dispersion, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

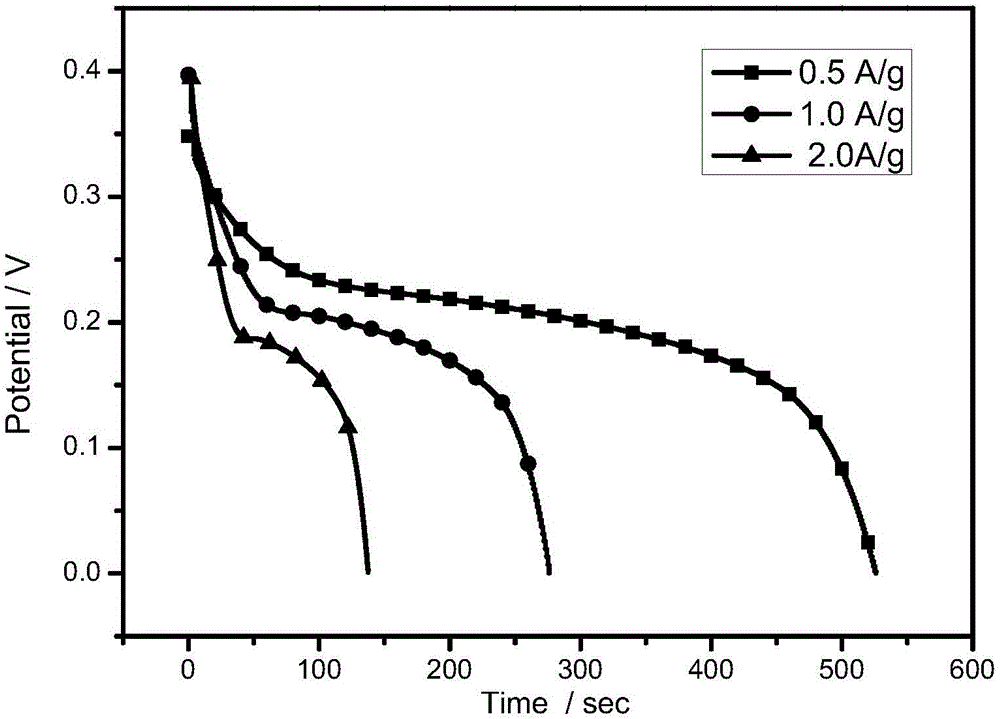

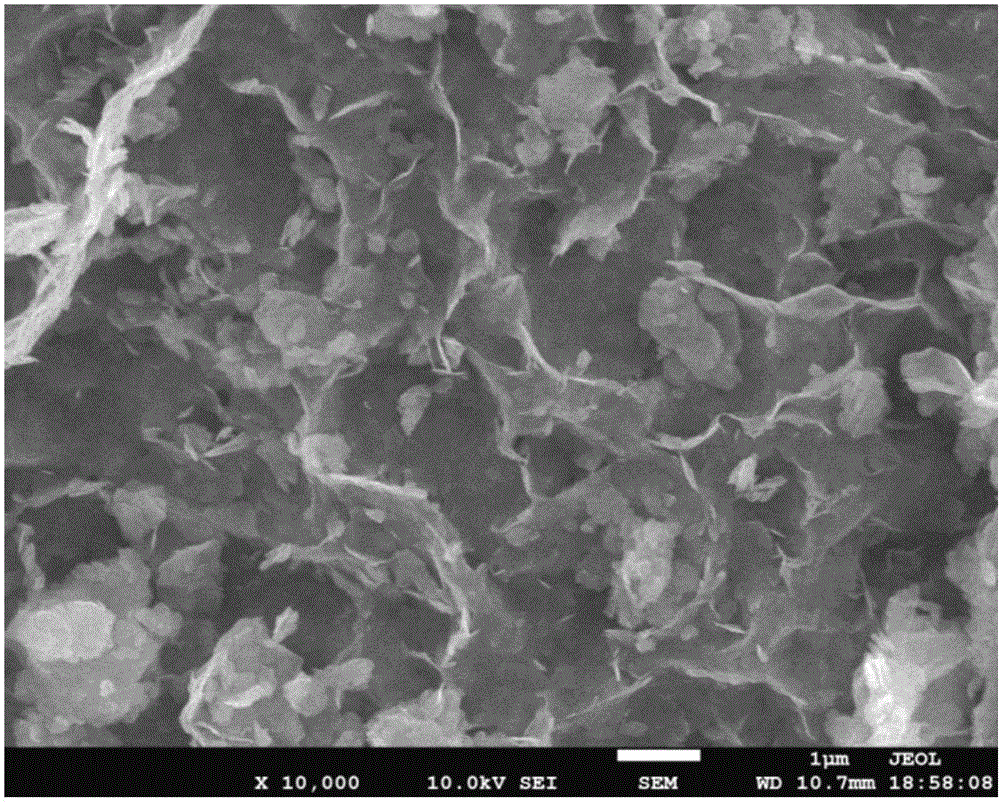

Embodiment 1

[0028] The graphite oxide produced by the Hummers method was ultrasonically treated in deionized water, the ultrasonic time was 10min, the ultrasonic power was 600W, and the obtained concentration was 0.1mgmL -1 Negatively charged graphene oxide solution. 2.0137g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 200ml of deionized water to obtain a concentration of 0.035molL -1 Nickel nitrate solution, magnetically stirred for 30min, then added dropwise NH 3 ·H 2 0 and constantly stirring, until the pH of the solution reaches 8, continue to stir for 20min, leave standstill 3h, obtain the nickel hydroxide solid precipitation after the suction filtration of gained precipitation solution 2 times then; Get nickel hydroxide precipitation 0.5g and add 300ml deionized water again through Ultrasonic treatment for 0.3h to obtain a positively charged nickel hydroxide suspension. According to the ratio of graphene oxide and nickel hydroxide mass ratio of 1:5, the graphene oxide aqueous solut...

Embodiment 2

[0031] The graphite oxide produced by the Hummers method was ultrasonically treated in deionized water, the ultrasonic time was 15min, the ultrasonic power was 650W, and the obtained concentration was 0.5mgmL -1 Negatively charged graphene oxide solution. 2.0926g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 400ml of deionized water to obtain a concentration of 0.018molL -1 Nickel nitrate solution, magnetically stirred for 10min, then added dropwise NH 3 ·H 2 0 and constantly stirring, until the solution pH reaches 8.5, continue to stir for 25min, leave standstill 8h, obtain nickel hydroxide solid precipitation after the suction filtration of gained precipitation solution 3 times then; Get nickel hydroxide precipitation 0.6g and add 400ml deionized water again through 0.4h ultrasonic treatment to obtain a positively charged nickel hydroxide suspension. Mix the graphene oxide aqueous solution and nickel hydroxide suspension according to the solute mass ratio of 1:7, stir for 25...

Embodiment 3

[0034] The graphite oxide produced by the Hummers method was ultrasonically treated in deionized water, the ultrasonic time was 25min, the ultrasonic power was 700W, and the obtained concentration was 1mgmL -1 Negatively charged graphene oxide solution. 3.1074g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 300ml of deionized water to obtain a concentration of 0.036molL -1 Nickel nitrate solution, magnetically stirred for 40min, then added dropwise NH 3 ·H 20 and constantly stirring, until the pH of the solution reaches 9, continue to stir for 30min, leave standstill 10h, then obtain nickel hydroxide solid precipitation after the suction filtration of gained precipitation solution 3 times; Get nickel hydroxide precipitation 0.9g and add 500ml deionized water again through 0.8h ultrasonic treatment to obtain a positively charged nickel hydroxide suspension. Mix the graphene oxide aqueous solution and nickel hydroxide suspension according to the solute mass ratio of 1:9, stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com