ovmi optical gradient magnetic ink printed matter online detection system and method

A magnetic ink and detection system technology, which is applied in the direction of optical testing for flaws/defects, etc., to improve product quality and safety, improve quality control, and realize the effect of downloading and uploading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

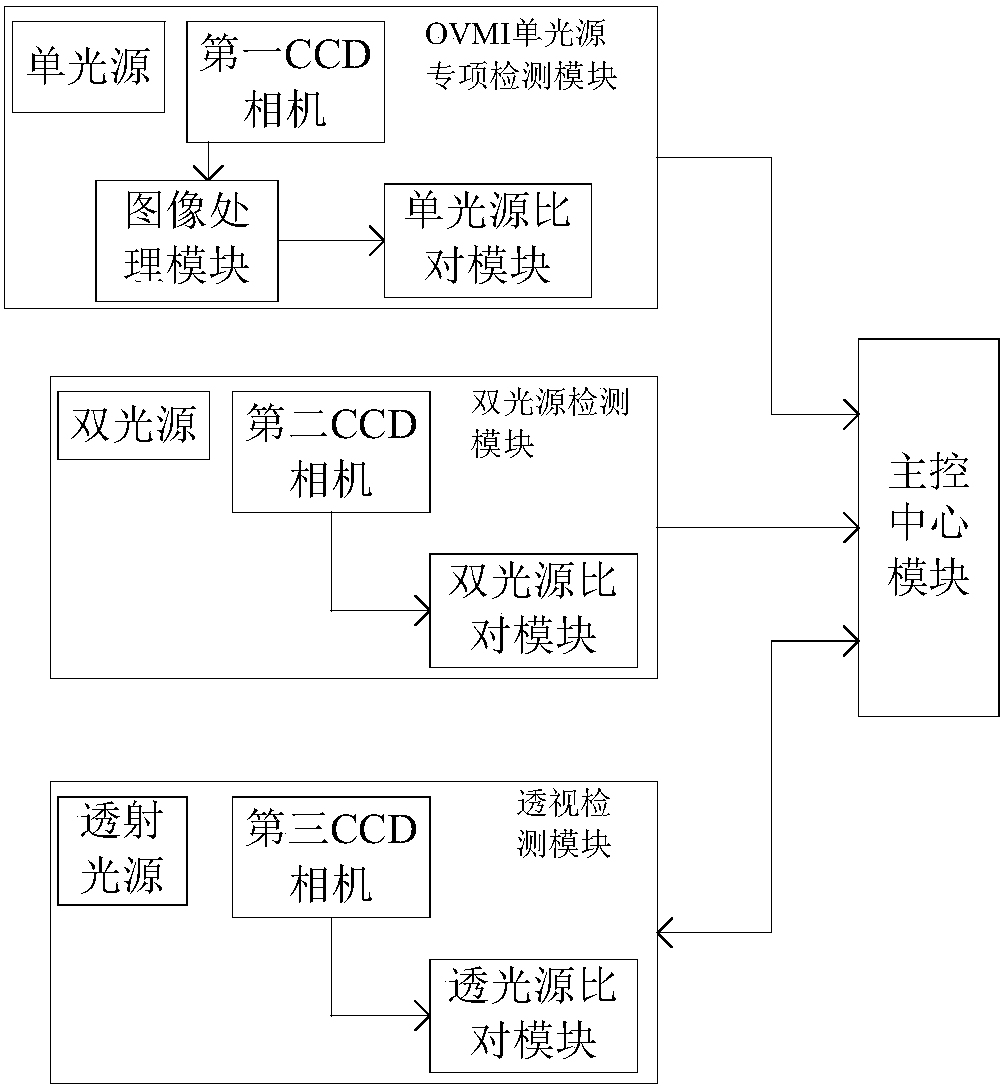

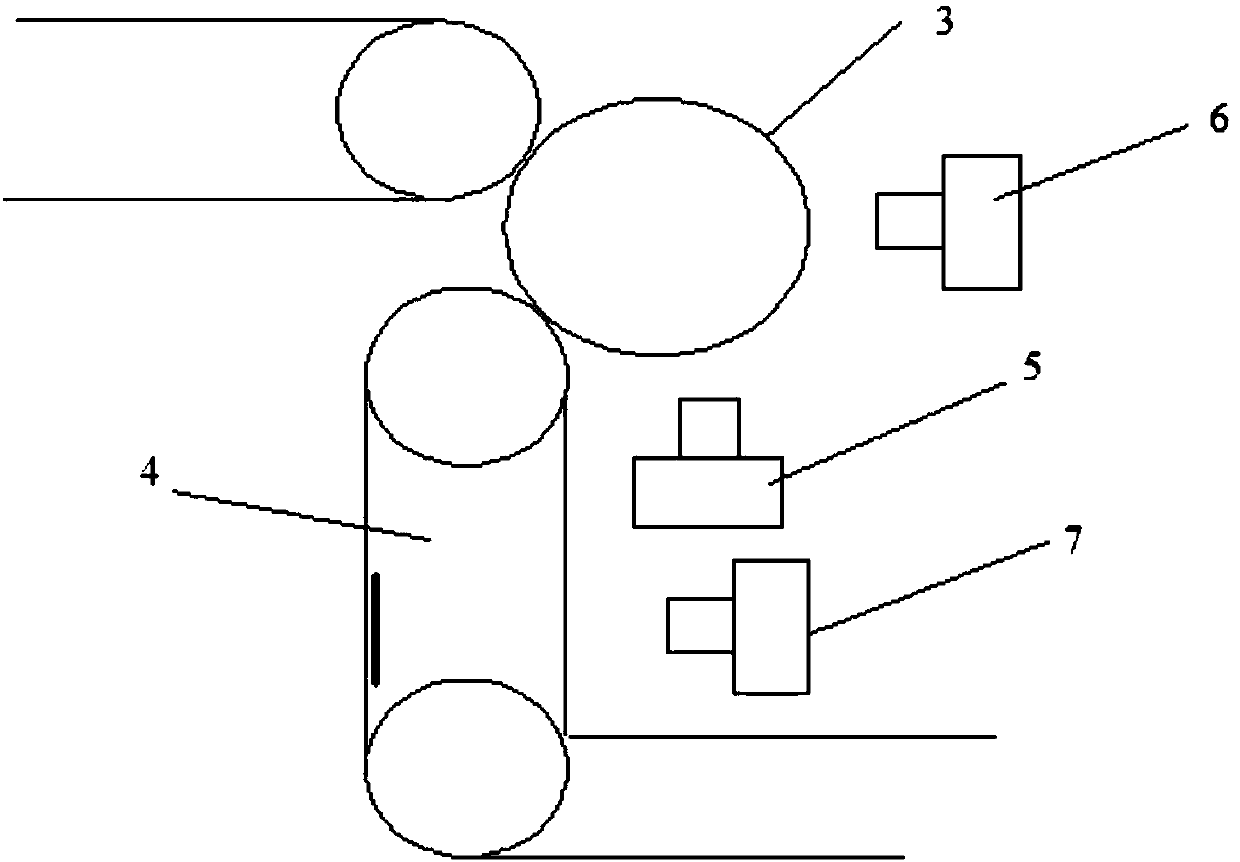

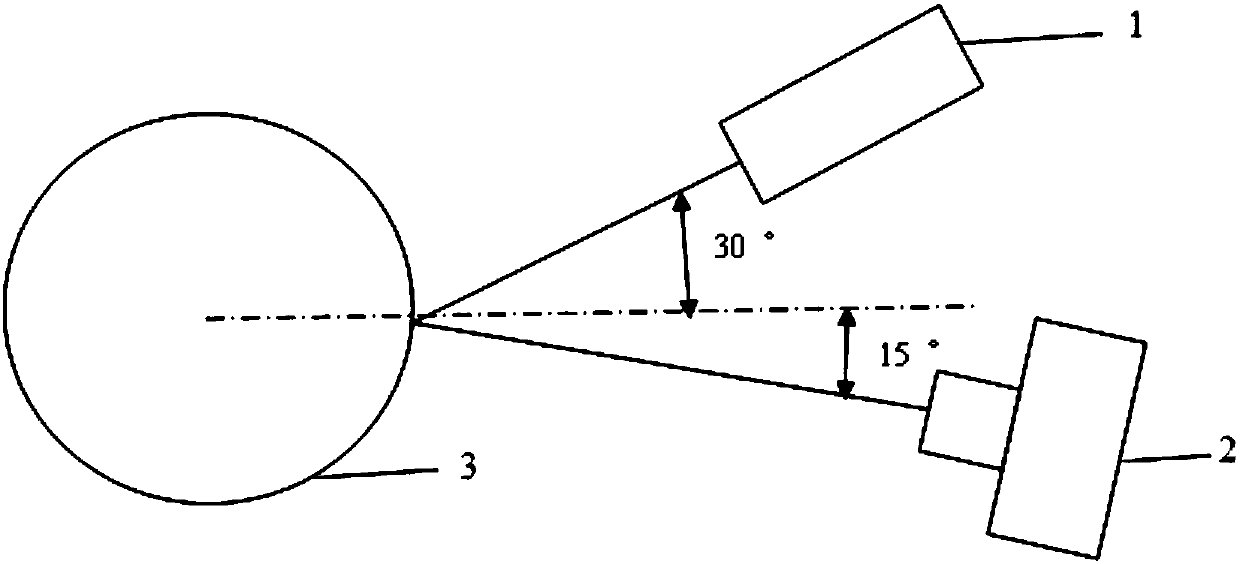

[0058] The layout of each detection module of OVMI pattern detection is as follows: figure 2 As shown: the detection system is to install OVMI single light source special detection module 5 and dual light source detection module 6 on the detection cylinder of the printing machine respectively, and install the perspective detection module 7 on the paper delivery chain. According to the anti-counterfeiting characteristics of the OVMI scroll bar, simulate the artificial quality evaluation method, use a single light source at the detection point, select a strip-shaped white LED light source, and its installation direction is parallel to the OVMI pattern scroll bar and parallel to the axis of the detection roller. At the same time, the single light source The angle between 1 and the normal line of the detection cylinder 3 is 0°-40°, the angle between the first CCD camera 2 and the normal line of the detection cylinder 3 of the printing press is 0°-30°, such as image 3 shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com