Bi-directional shearing speckle interference system based on spatial carrier and measurement method

A speckle interference, bidirectional technology, used in optical testing flaws/defects and other directions, can solve the problems of not ensuring the consistency of the measured object deformation, difficulty in unified quantification processing, and increasing the complexity of the measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

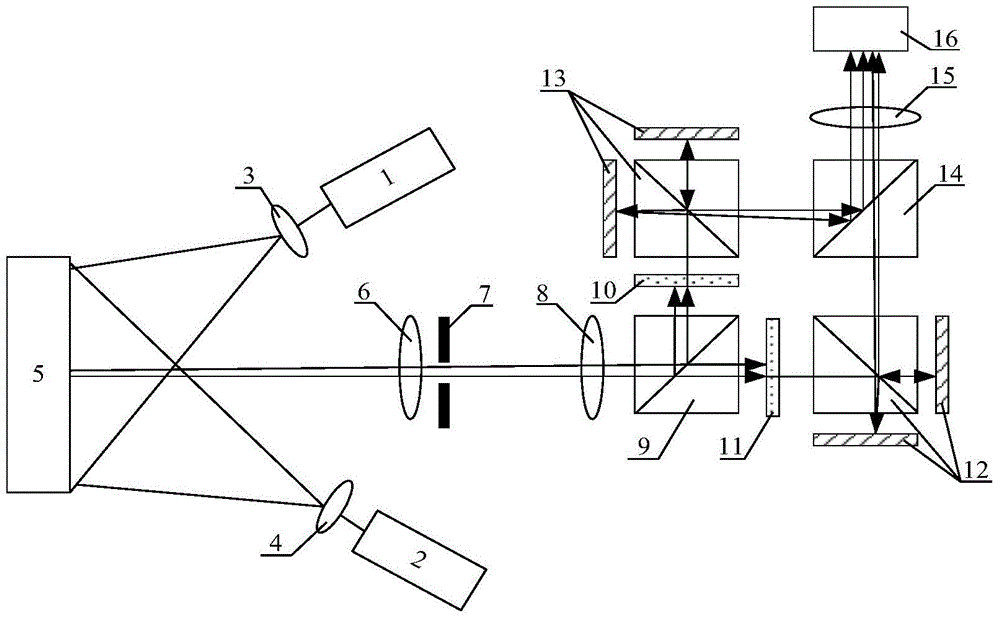

[0060] In this embodiment, the structural form of the spatial carrier-based two-way shear speckle interference system is:

[0061] The first light source 1 and the second light source 2 are respectively set as illumination light sources; the first light source 1 passes through the first beam expander 3, and the second light source 2 irradiates the measured surface 5 at the same time after passing through the second beam expander 4. The surface of face 5 forms a diffuse reflection of light.

[0062] After the diffuse reflection light passes through the imaging lens 6, the aperture 7 and the 4f system front lens 8 in sequence, it is split in the beam splitting prism 9 according to the ratio of 5:5 to form the first beam and the second beam whose optical axes are 90 degrees to each other. beam.

[0063] The first light beam filters out the diffuse reflection light formed by the second light source on the measured surface 5 through the first optical filter 11, and obtains the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com