Particle chain shock absorber and particle chain damping measuring method

A shock-absorbing damping and testing method technology, applied in the field of shock-absorbing dampers, can solve problems such as the narrow shock-absorbing frequency band of liquid dampers, and achieve the effects of obvious shock-absorbing effect, easy maintenance, and easy dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] To protect the descent landing gear, it is necessary to attenuate the shock as much as possible. For example, the landing of an aerospace probe is achieved through structural design and impact attenuation devices to achieve a safe landing. Because the granular material can pass through friction and inelastic collision between particles, it has good energy dissipation capacity and can play a certain shock absorption effect. Therefore, Embodiment 1 of the present invention provides a particle chain shock-absorbing damping device 1.

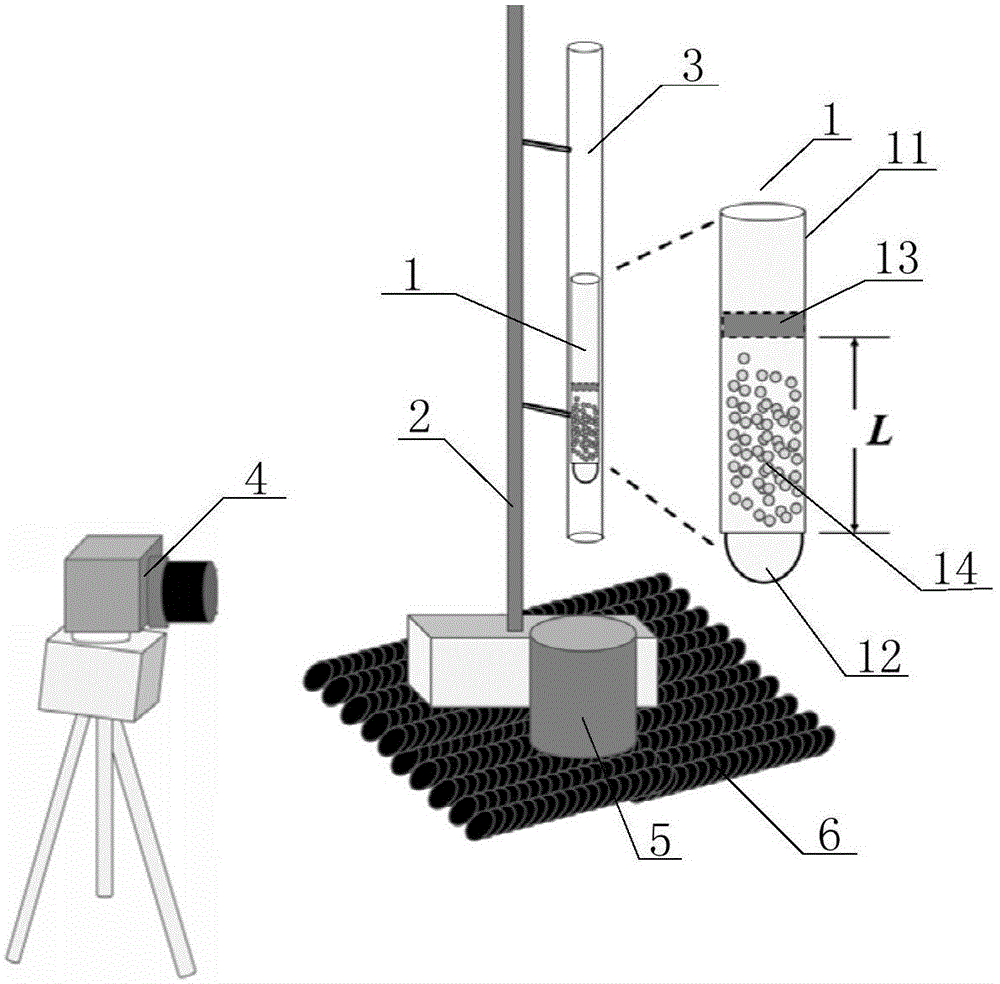

[0039] figure 1 It is a schematic structural view of the test method of the particle chain shock absorbing and damping device of the present invention, figure 2 It is a structural schematic diagram of the granular chain shock-absorbing damping device of the present invention. Such as figure 1 and figure 2 As shown, the particle chain damping device 1 includes: a hollow cylinder 11 , an acrylic glass ball 12 , a baffle 13 and a pluralit...

Embodiment 2

[0050] This embodiment provides a particle chain shock absorption and damping test method, which test method includes the following steps:

[0051] (a), the acrylic glass ball 12 is embedded in the bottom of the hollow cylinder 11, and then a plurality of particle chains 14 are placed on the lower surface of the hollow cylinder 11 in a spiral initial placement state, each particle chain Including at least 8 particles, and finally the baffle plate 13 is detachably fixed on the upper part of the hollow cylinder 11, finally forming the particle chain shock-absorbing damping device 1;

[0052] (b), place the fixed bracket 2 on the level ground to fix the smooth glass conduit 3, the smooth glass conduit 3 is a conduit with upper and lower openings, its radius is slightly larger than the radius of the hollow cylinder 11, and the particle chain shock-absorbing damping device 1 Placed inside the smooth glass conduit 3. Among them, the purpose of the smooth glass conduit 3 is to guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com