A design method of armored mud discharge pipe and its mud discharge pipe

A design method and technology of sludge discharge pipe, applied in the direction of pipes/pipe joints/pipes, hoses, pipes, etc., can solve the problem that the conveying resistance affects the conveying speed, the wear resistance of the inner pipe wall is different, and the bending degree cannot be guaranteed. and other problems, to achieve the effect of ensuring wear resistance, novel design concept, and meeting bending requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

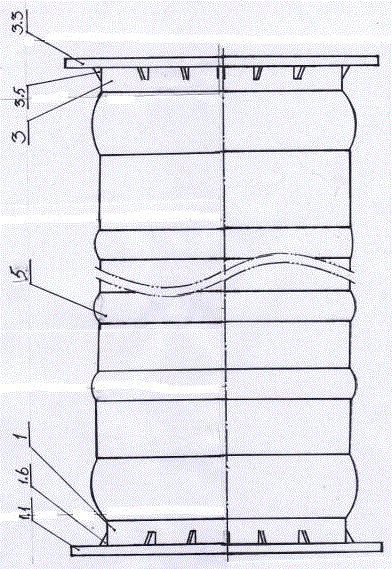

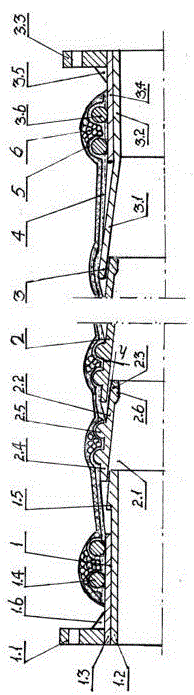

[0030] The design method of a kind of armored mud discharge pipe of embodiment 1 of the present invention, comprises the overall design of inlet end pipe, armored pipe body and outlet end connection pipe and the specific design of each component, the armored mud discharge pipe of described The design method is based on the premise of meeting the technical requirements of the bending degree ≥ 35°, and adopts an overall design scheme of front and rear armored sleeves for the inlet end pipe, armored pipe body and outlet end pipe. The details include: the inlet end pipe It is a casing that combines the inner and outer tubes and has a flange at the inlet end, two ring-shaped positioning fastening rings on the outside, and a tapered boss on the outside of the outlet end and is inserted into the armored tube body. The inner cavity of the inlet end; the armored pipe body is connected by a plurality of conical pipes. The diameter of the cavity is the outlet end, and the outlet end of t...

Embodiment 2

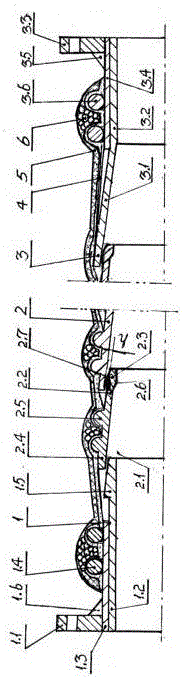

[0045] The design method of a kind of armored mud discharge pipe of the embodiment 2 of the present invention, comprises the overall design and the specific design of each parts of the inlet end pipe, the armored pipe body and the outlet end pipe, the armored pipe described in the embodiment 2 of the present invention The design method of the mud discharge pipe is based on the premise of meeting the technical requirements of the bending degree ≥ 35°. The overall design scheme of the front and rear armored sleeves is adopted for the inlet end pipe, armored pipe body and outlet end pipe. The details are as follows: The inlet-end connection pipe described above is a casing that combines inner and outer pipes, and a flange is provided at the inlet end, and two ring-shaped positioning fastening rings are arranged on the outer side, and a tapered boss is arranged on the outer side of the outlet end for insertion. In the inner cavity of the entrance end of the armored pipe body; the a...

Embodiment 3

[0061] A design method of an armored mud discharge pipe according to Embodiment 3 of the present invention, including the overall design of the inlet end pipe, the armored pipe body and the outlet end pipe, and the specific design of each part. The armored pipe described in Embodiment 3 of the present invention The design method of the mud discharge pipe is based on the premise of meeting the technical requirements of the bending degree ≥ 35°. The overall design scheme of the front and rear armored sleeves is adopted for the inlet end pipe, armored pipe body and outlet end pipe. The details are as follows: The inlet-end connection pipe described above is a casing that combines inner and outer pipes, and a flange is provided at the inlet end, and two ring-shaped positioning fastening rings are arranged on the outer side, and a tapered boss is arranged on the outer side of the outlet end for insertion. In the inner cavity of the entrance end of the armored pipe body; the armored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com