Integral Formwork and Pouring Construction Method of Tunnel Inverted Arch Combination

A technology of integral formwork and construction method, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of labor-intensive and time-consuming construction efficiency, and achieve the effect of improving construction quality, improving construction progress, and easy construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

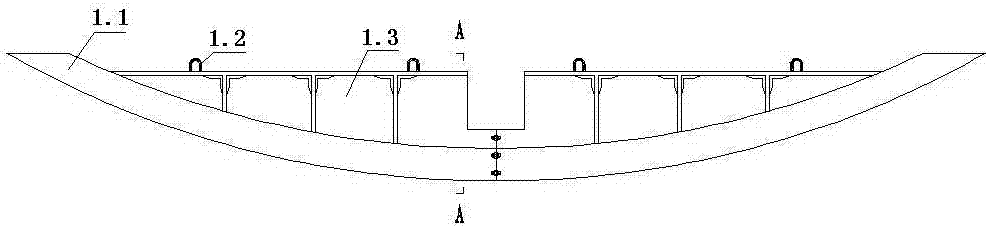

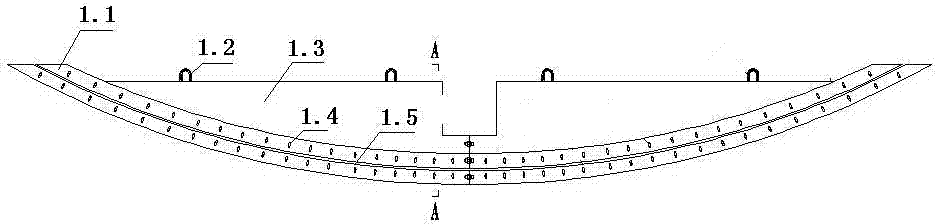

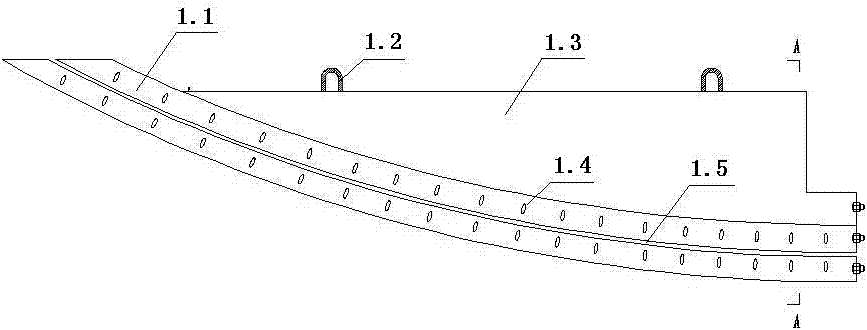

[0042] A tunnel inverted arch combined overall formwork, comprising an inverted arch and filling combined shaped end formwork 1, an inverted arch side arc formwork 2 and a central gutter formwork 3.

[0043] Such as figure 1 , 2 , 3, and 4, the described inverted arch and filling combination shaping end formwork includes an arc-shaped inverted arch formwork 1.1 and a filling end formwork 1.3 above the inverted arch formwork 1.1, and the bottom of the inverted arch formwork 1.1 is provided with some The steel bar hole 1.4 is set, and the bottom of the inverted arch formwork 1.1 is also provided with a waterstop clamping groove 1.5 arranged along the arc of the inverted arch formwork. 1.3 The upper side of the middle part is provided with a groove for making a central gutter.

[0044] Such as Image 6 , 7 As shown, the inverted arch side arc mold 2 is assembled from several small inverted arch side arc molds, each small inverted arch side arc mold includes an arc panel 2.1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com