Well cementation casing or tubing sliding sleeve without limit on number of segments or clusters

A sliding sleeve and well cementing technology, which is applied to wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve the problem of inability to implement drilling and grinding operations, affect production and operation, and fail to meet the multi-stage number of oil and gas wells To meet the needs of fracturing reconstruction and other issues, to achieve the effect of facilitating production and post-operation, reducing the risk of manual operation, and improving the effect of fracturing reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

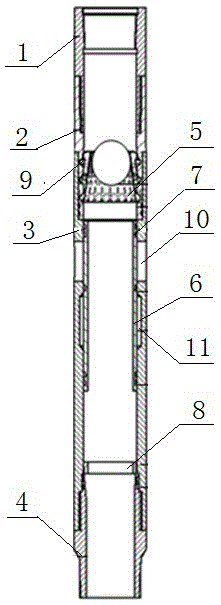

[0026] This embodiment provides a cementing casing or tubing sleeve with unlimited segments and clusters, such as figure 1 As shown, it includes an upper joint 1, a diameter reducing cylinder 2, a sliding sleeve body 3 and a lower joint 4 from top to bottom. The upper inner wall of the sleeve body 3 is threaded, the lower inner wall of the sliding sleeve body 3 is threaded with the upper outer wall of the lower joint 4, and the inner wall of the reducing tube 2 is equidistantly provided with multiple rings of grooves 9 so that the inner wall of the reducing tube 2 forms a concave-convex part There are spaced variable diameter areas, on which an elastic cylinder 5 is installed; the middle of the sliding sleeve body 3 is evenly distributed with a plurality of fracturing ports 10 along the circumferential direction, and the inner wall of the sliding sleeve body 3 is provided with a diameter expanding area 11 , the length of the diameter-expanding area 11 is greater than the lengt...

Embodiment 2

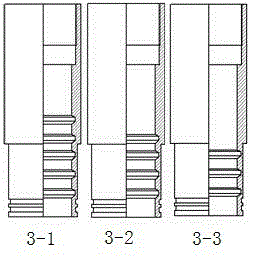

[0032] This embodiment further explains the implementation process of Example 1. During the implementation process, the number of grooves 9 designed on the inner wall of the reducing cylinder 2 depends on the number of sections to be fractured. The first section of the sliding sleeve shall prevail, and one section shall be added. The convex and concave strokes increase by one. The protrusions and grooves of the variable diameter tube in the first section of the sliding sleeve body should be designed according to the length of the elastic tube 5. The design principle is to place the lower end of the elastic tube 5 in the bottommost groove (placed here so that the lower end of the elastic tube is in the expanding position). Diameter state), at this time, the position of the upper end of the elastic cylinder is the position of the corresponding convex groove (it is placed here so that the upper end of the elastic cylinder is in a reduced diameter state). Therefore, in this embodi...

Embodiment 3

[0037] Taking three-stage cementing casing sliding sleeves to fracture a four-section well in layers as an example, the working process of cementing casings or tubing sliding sleeves with unlimited sections is illustrated.

[0038] The present invention connects three-stage cementing casing sliding sleeves according to the number of fracturing layers, and the sliding sleeves are the third sliding sleeve, the second sliding sleeve, and the first sliding sleeve from top to bottom, and the pipe string is lowered to the fracturing layer such as Figure 8 . The third sliding sleeve, the second sliding sleeve, and the first sliding sleeve are designed as follows: Figure 3-1 shown. The initial installation position of the elastic cylinder is as follows from top to bottom: Figure 5-1 , Figure 5-2 , Figure 5-3 , The sliding sleeves are installed with C rings, and balls 1, 2, and 3 are of the same size.

[0039] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com