Clamping pliers device and method for using same

A technology of punching pliers and pliers, which is applied in earthwork drilling, drilling equipment, drill pipes, etc., and can solve problems such as complex on-site maintenance, failure of clamping cylinder seals, failure of cylinder rods and seals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

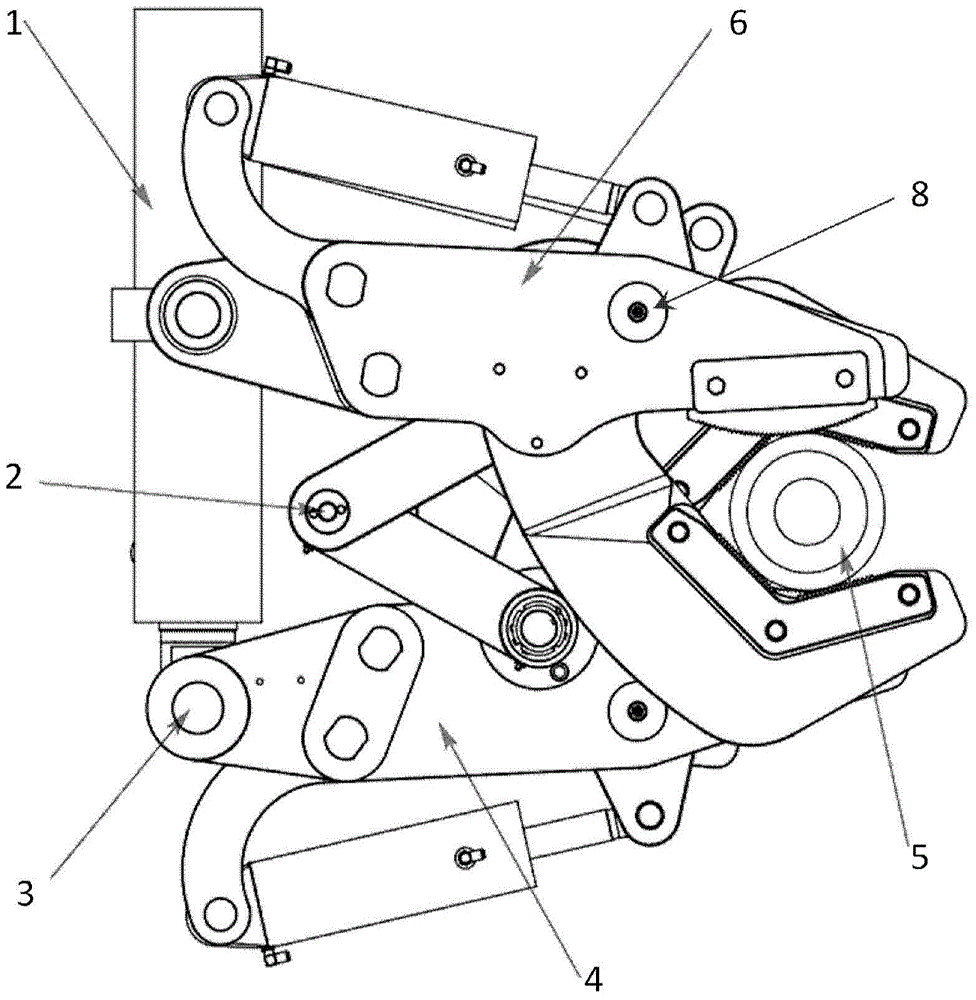

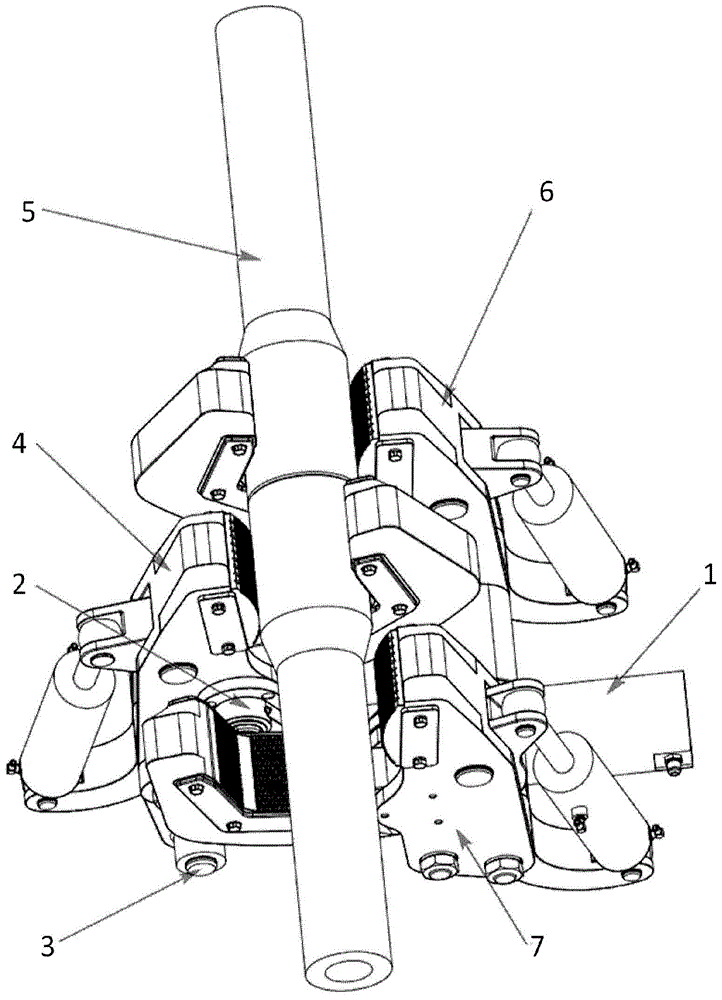

[0036] figure 1 with figure 2 A top schematic view and a perspective schematic view of a punch clamp device according to an embodiment of the present invention are respectively shown. As shown in the figure, the punch clamp device includes an upper pliers 6, a lower pliers 7, and a middle pliers 4 installed between the upper pliers and the lower pliers. The punching pliers device also includes two sets of connecting structures 2 which are installed between the lower pliers 7 and the middle pliers 4 and between the middle pliers 4 and the upper pliers 6 respectively.

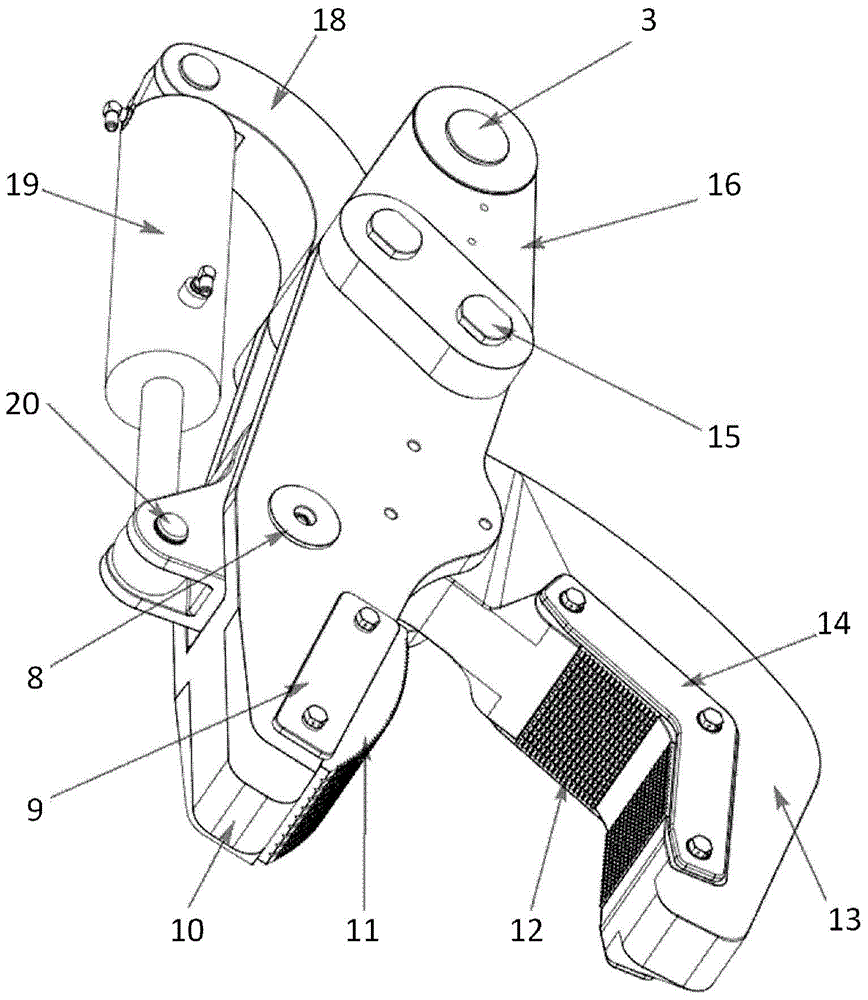

[0037] image 3 A perspective schematic diagram of the middle pliers of the punch pliers device according to an embodiment of the present invention is shown. As shown in the figure, the middle pliers 4 includes a pliers body, the pliers body includes: a pliers head body, the pliers head bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com