Low-temperature Lycra free-cut double-sided knitting fabric

A technology of knitted fabrics and tailoring at will, applied in the field of textile fabrics, can solve the problems of high manufacturing cost, discomfort, and unsophisticated clothing effects, etc., and achieve the effect of reducing production costs, low cost, and overall flatness and beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below by means of the accompanying drawings and examples.

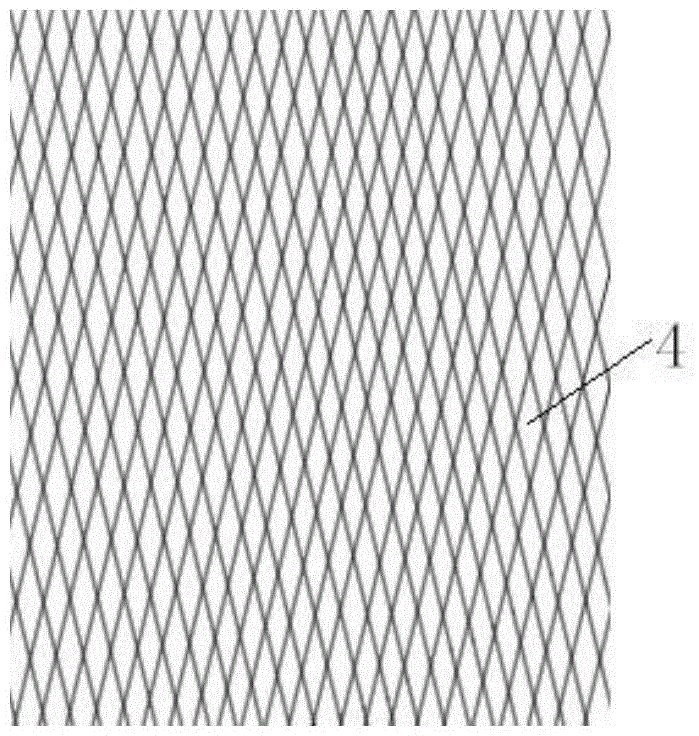

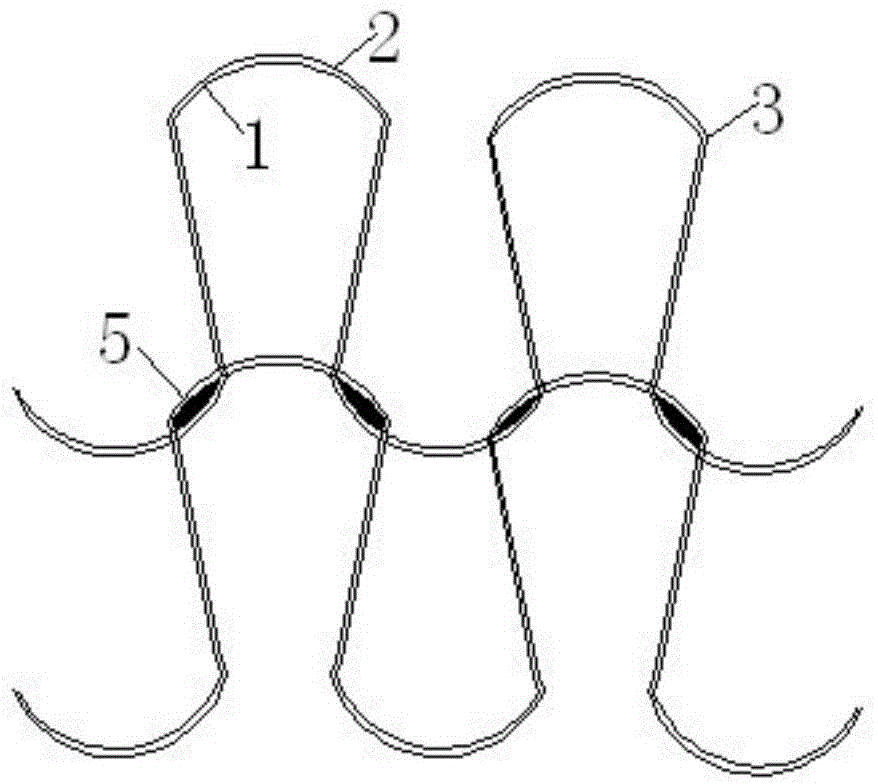

[0013] Such as figure 1 and figure 2 As shown, a low-temperature Lycra double-sided knitted fabric according to the present invention is composed of a mixed yarn 3 interwoven with a low-temperature Lycra yarn 1 and a textile fiber yarn 2, and the mixed yarn 3 is interwoven into a The fabric 4, the mixed yarn 3 adopts a rib or double rib weave structure, the fabric 4 is a double-sided weft knitted structure, and the connection between the mixed yarn 3 is a mutual melting bonding point 5; The low-temperature Lycra yarn 1 is INVISTA EasySetLYCRA fiber; the textile fiber yarn 2 includes pure spinning or blended textile fiber; the yarn feeding ratio of the low-temperature Lycra yarn 1 and textile fiber yarn 2 is 1:1. The invention adopts low-temperature Lycra yarn and textile fiber yarn to form a thread, utilizes the characteristics of low-temperature Lycra yarn tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com