Molten steel calcium treatment process and its equipment

A technology for calcium treatment and molten steel, which is applied in the field of molten steel calcium treatment process and its equipment, can solve the problems that the efficiency and uniformity of calcium treatment cannot be guaranteed, the calcium treatment in the furnace cannot be realized, and the calcium alloy burns seriously, so as to ensure production safety performance, improve the effect of calcium treatment, and precisely control the composition of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

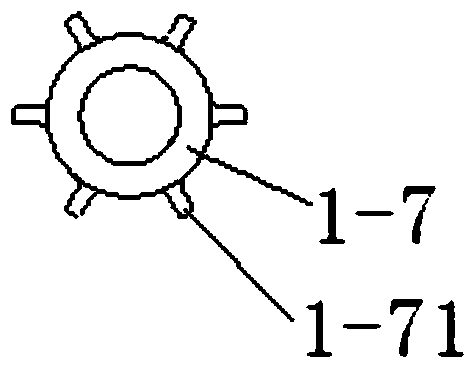

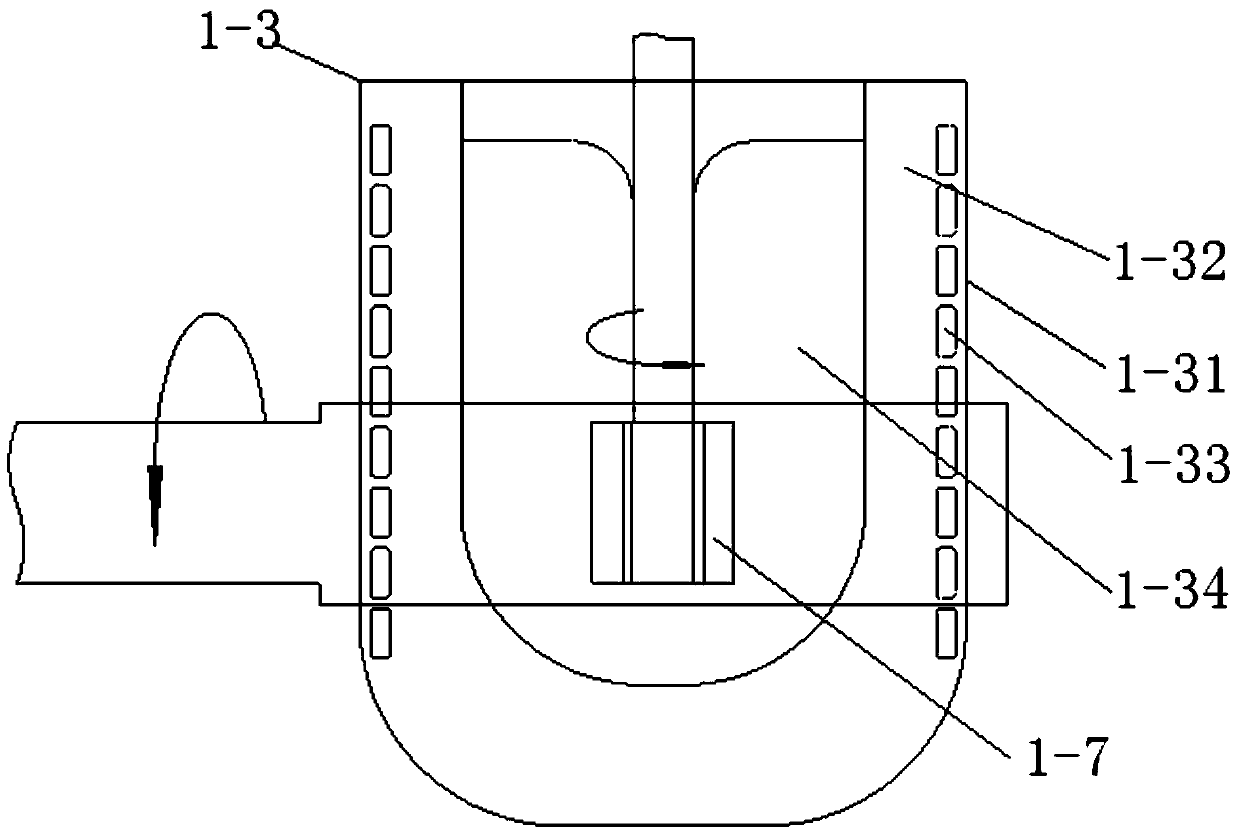

Method used

Image

Examples

Embodiment 1~3

[0031] Taking the molten steel calcium treatment equipment with a specification of 50kg as an example, the low-carbon aluminum-killed steel is subjected to calcium treatment and casting according to the above working process, and the composition and calcium content inspection is carried out after the casting is cooled. The product composition among the embodiment 1~3 sees the following table 1 (surplus is Fe):

[0032] Table 1

[0033]

[0034] The main process parameters and test results involved in Examples 1-3 are shown in Table 2 below, wherein the weight content of calcium in the calcium-iron alloy used is 30%, and the weight content of iron is 70%:

[0035] Table 2

[0036]

[0037] As can be seen from Table 2, mechanical agitation drives the circulating flow of molten steel in the induction furnace, creating good kinetic conditions for the uniformity of calcium treatment. In Examples 1 to 3, W Ca / W Als >0.1, a good calcium treatment effect is achieved; the yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com