Manmade beef bone button and preparing method thereof

A technology of bovine bones and buttons, which is applied in the field of clothing production, can solve the problems of high price, poor button surface uniformity, and easy color difference, etc., and achieve a stable and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

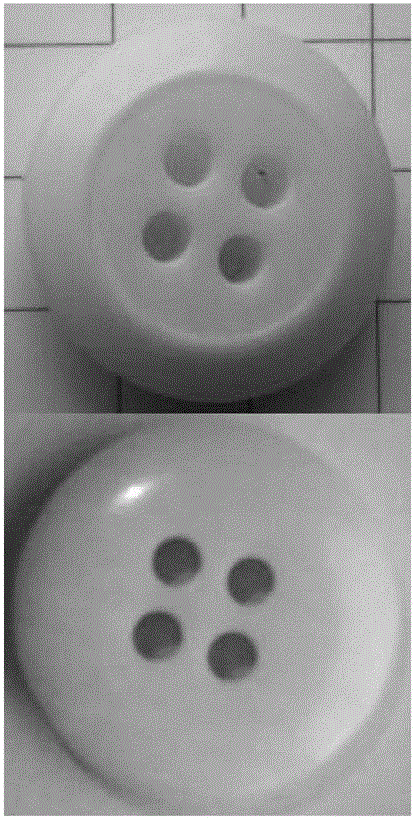

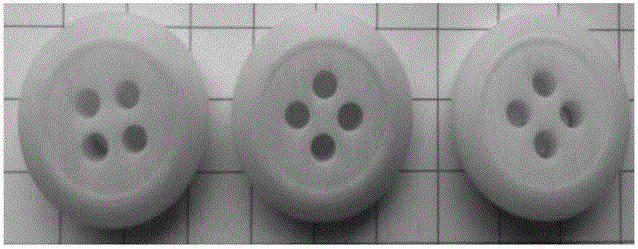

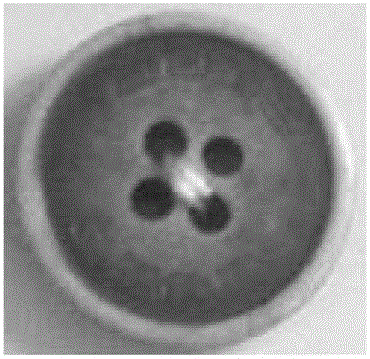

Image

Examples

preparation example Construction

[0050] The present invention provides a method for preparing artificial bovine bone buttons, which is characterized in that it comprises the following steps:

[0051] A) After mixing the unsaturated polyester resin, the colorant, the accelerator and the initiator, a blank-making slurry A is obtained; the density of the blank-making slurry A is 1.25-5 g / mL;

[0052] After mixing the unsaturated polyester resin, color paste, soluble fine particulate filler, accelerator, styrene, and initiator, a blanking slurry B is obtained; the viscosity of the blanking slurry B is 300-900 mPa·s;

[0053] B) After the blanking slurry A and the blanking slurry B obtained in the above step A) are subjected to a blanking process, an artificial bovine bone button is obtained.

[0054] In the above-mentioned preparation method of the present invention, the preferred principle and added amount of the raw materials used are consistent with the preferred principle and added amount of the aforementioned mixed s...

Embodiment 1

[0082] First, after stirring and mixing 50 g of unsaturated polyester resin, 25 g of titanium dioxide, 2 g of cobalt naphthenate and 2 g of methyl ethyl ketone peroxide, a blanking slurry A with a density of 3.65 g / mL is obtained;

[0083] Stir and mix 1000g unsaturated polyester resin, 0.5g white pulp, 0.02g yellow pulp, 0.01g brown pulp, 40g soluble fine granular filler, 8g cobalt naphthenate, and add 40g styrene after heating to 30°C. After adding 10g of methyl ethyl ketone peroxide, a blank-making slurry B with a viscosity value of 638 mPa·s is obtained;

[0084] Then, evenly spread the blank-making slurry B obtained in the above steps on the inner wall of the centrifuge. After turning on the centrifuge at 60 rpm, 2 minutes later, before the blank-making slurry B is completely solidified, use an automatic air pressure spray gun Spray the blank-making slurry A back and forth repeatedly on the travel frame at a uniform speed, so that the blank-making slurry A is gradually sprayed...

Embodiment 2

[0089] First, after stirring and mixing 50 g of unsaturated polyester resin, 20 g of colorant, 1.8 g of cobalt naphthenate and 1.8 g of methyl ethyl ketone peroxide, a blank-making slurry A with a density of 3.26 g / ml is obtained;

[0090] Stir and mix 1000g unsaturated polyester resin, 0.5g white pulp, 2g red pulp, 2g blue pulp, 2g black pulp, 40g soluble fine granular filler, 8g cobalt naphthenate, and add 50g styrene after heating to 30℃ After adding 10 g of methyl ethyl ketone peroxide, a blank slurry B with a viscosity of 553 mPa·s was obtained.

[0091] Then, evenly spread the blank-making slurry B obtained in the above steps on the inner wall of the centrifuge. After turning on the centrifuge at 120 rpm, after 2 minutes, before the blank-making slurry B is completely solidified, use an automatic air pressure spray gun Spray the blanking slurry A back and forth repeatedly on the stroke frame, so that the blanking slurry A is gradually sprayed out in a linear shape under the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com