A high-efficiency additive for machine-blasted mortar

A technology of machine-sprayed mortar and additives, which is applied in the field of dry-mixed mortar, can solve problems such as difficulties in the promotion of mechanical spraying construction, poor adhesion of substrates, and short opening time, and achieve low cost, good workability, and reduced mixing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

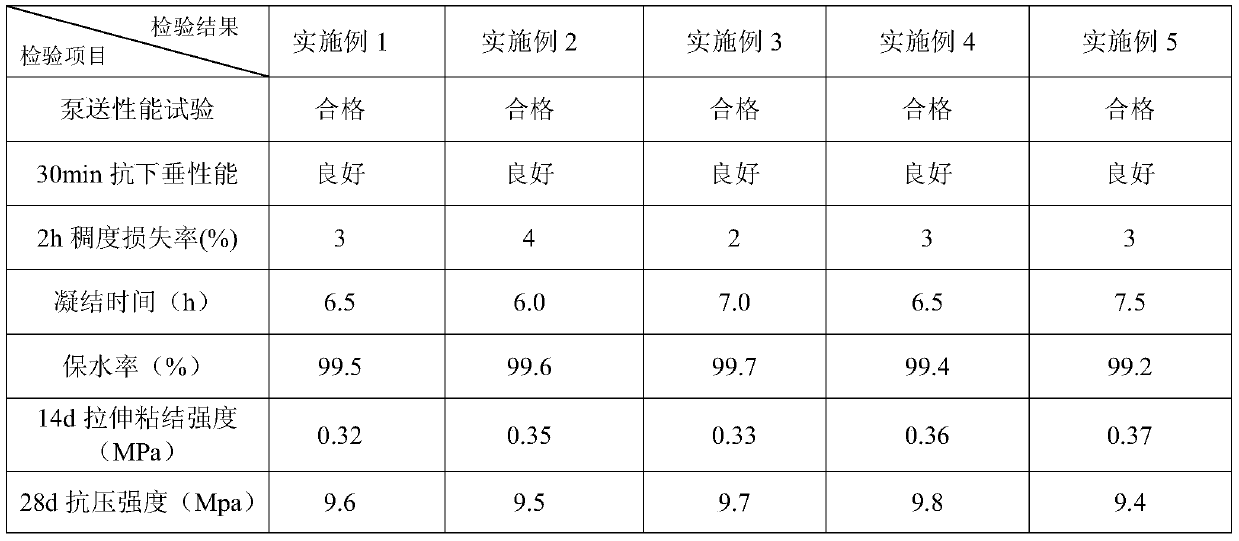

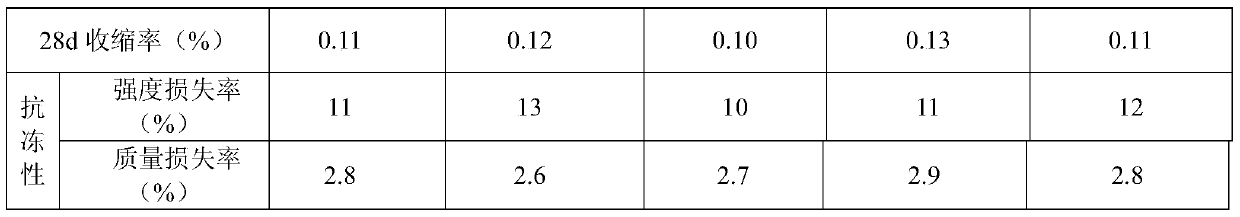

Examples

Embodiment 1

[0031] This embodiment provides a high-efficiency additive for machine-blasting mortar, which is composed of the following components by weight: 50 parts by weight of water-retaining agent, 2 parts by weight of coagulation-adjusting enhancer, and 6 parts by weight of polycarboxylate superplasticizer , 12 parts by weight of anti-cracking agent, 0.5 parts by weight of air-entraining agent, and 30 parts by weight of fly ash.

[0032] Wherein, the water retaining agent is composed of 90 parts by weight of hydroxyethyl methylcellulose and 10 parts by weight of modified starch ether.

[0033] Wherein, the coagulation-regulating enhancer is calcium formate.

[0034] Wherein, the anti-cracking agent is composed of 60 parts by weight of polypropylene fiber and 40 parts by weight of lignocellulose.

[0035] Among them, the polycarboxylate water reducer is prepared by the following preparation method: put 205 parts by weight of prenol polyoxyethylene ether into the reactor, add 85 parts...

Embodiment 2

[0038] This embodiment provides a high-efficiency additive for machine-sprayed mortar, which is composed of the following components by weight: 40 parts by weight of water-retaining agent, 3 parts by weight of coagulation-adjusting enhancer, and 5 parts by weight of polycarboxylate superplasticizer , 115 parts by weight of anti-cracking agent, 0.1 part by weight of air-entraining agent, and 40 parts by weight of fly ash.

[0039] Wherein, the water retaining agent is composed of 85 parts by weight of hydroxyethyl methylcellulose and 15 parts by weight of modified starch ether.

[0040] Wherein, the coagulation-adjusting enhancer is citric acid.

[0041] Wherein, the anti-cracking agent is composed of 55 parts by weight of polypropylene fiber and 45 parts by weight of lignocellulose.

[0042]Among them, the polycarboxylate water reducer is prepared by the following preparation method: put 200 parts by weight of prenol polyoxyethylene ether into the reactor, add 90 parts by wei...

Embodiment 3

[0045] This embodiment provides a high-efficiency additive for machine-blasting mortar, which is composed of the following components by weight: 60 parts by weight of water-retaining agent, 1 part by weight of coagulation-adjusting enhancer, and 8 parts by weight of polycarboxylate superplasticizer , 10 parts by weight of anti-cracking agent, 0.8 parts by weight of air-entraining agent, and 20 parts by weight of fly ash.

[0046] Wherein, the water retaining agent is composed of 95 parts by weight of hydroxyethyl methylcellulose and 5 parts by weight of modified starch ether.

[0047] Wherein, the coagulation-regulating enhancer is calcium sulfate.

[0048] Wherein, the anti-cracking agent is composed of 65 parts by weight of polypropylene fiber and 35 parts by weight of lignocellulose.

[0049] Among them, the polycarboxylate water reducer is prepared by the following preparation method: put 210 parts by weight of isopentenol polyoxyethylene ether into the reactor, add 80 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com