Precise clamp used for micro-miniature complex thin-walled part machining and control method of precise clamp

A thin-walled part, micro-miniature technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of easy loss or damage, loss of processing accuracy, small functional surface, etc., to achieve simple structure and compact layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

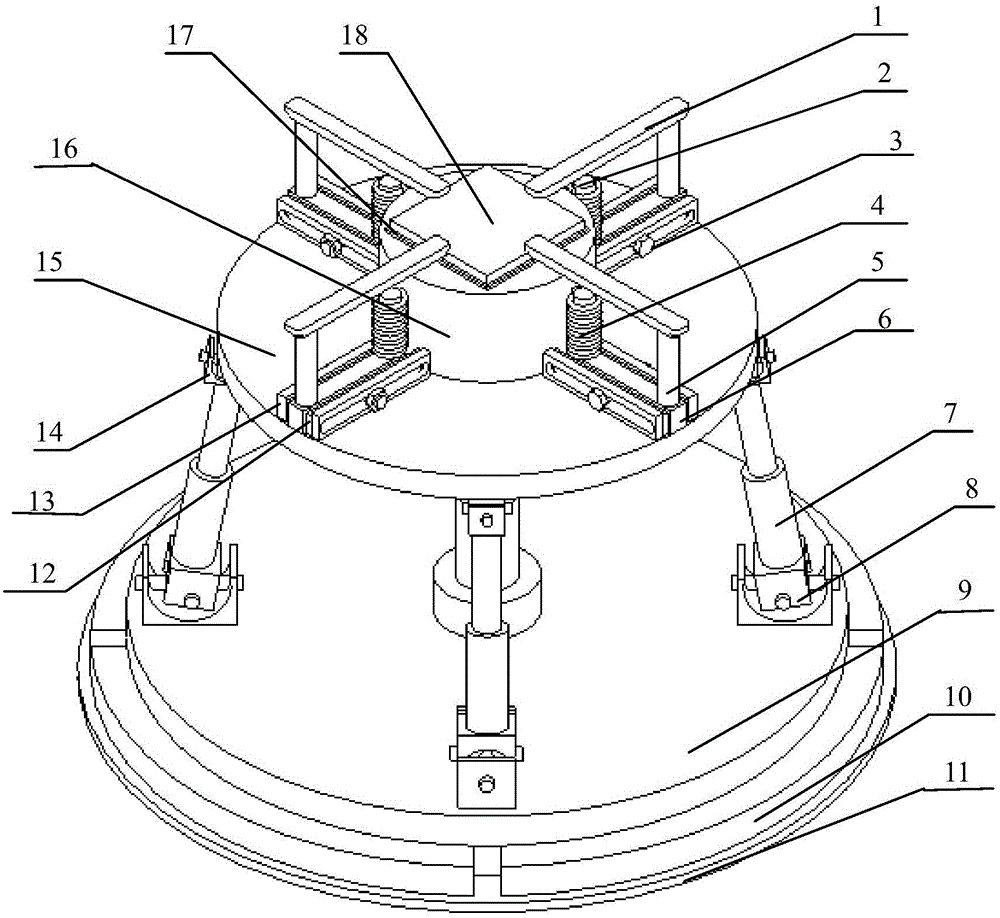

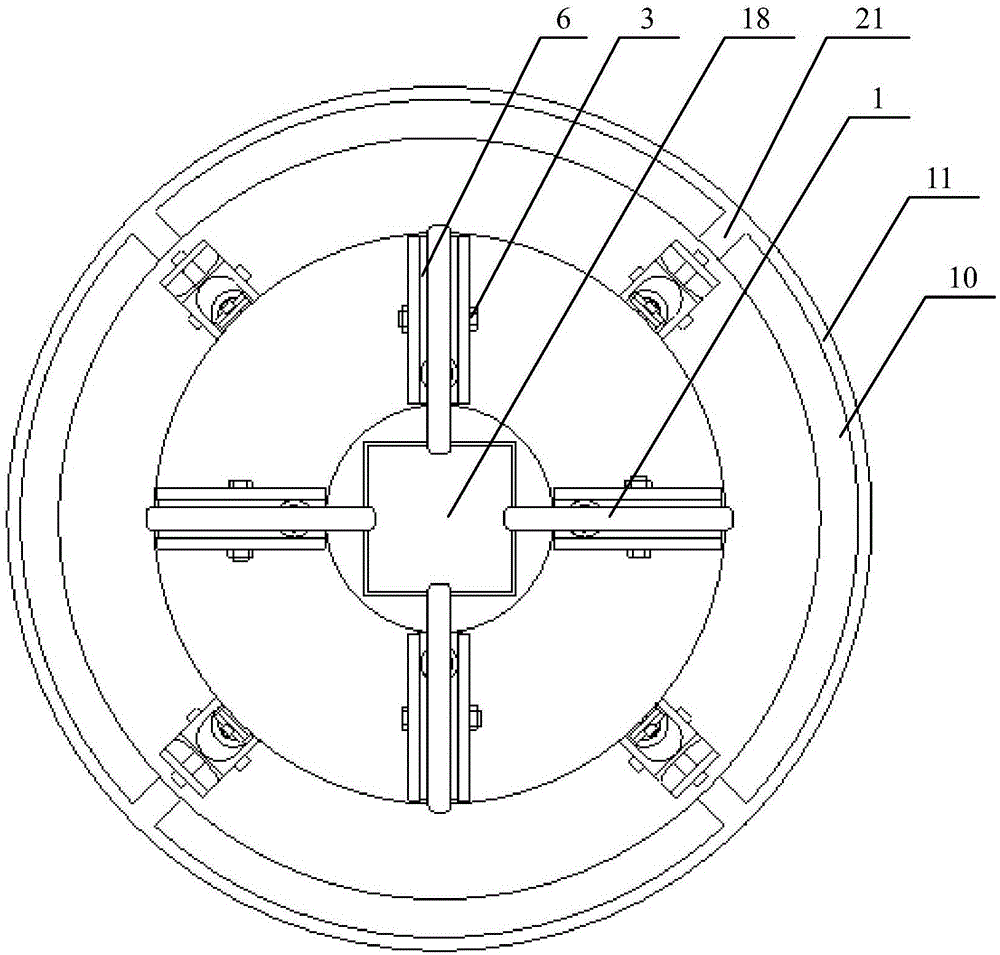

[0084] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0085] Such as Figure 1-4 As shown, the precision fixture for the processing of micro-miniature complex thin-walled parts of the present invention includes a base 9, a liftable deflection platform 15 and five gas-hydraulic damping cylinders; Two sections, the whole is in the shape of a flat stepped shaft;

[0086] The above-mentioned liftable deflection platform is a circular plate;

[0087] The above-mentioned base and the above-mentioned liftable deflection platform are arranged parallel to each other one by one, and are connected as a whole through the above-mentioned five gas-liquid damping cylinders;

[0088] Among the above-mentioned five gas-liquid damping cylinders, one is the central gas-liquid damping cylinder 20, and the central axis of the central gas-liquid damping cylinder is the same straight line as the connecting line between the above-mentioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com