Laser-double side arc compound welding method for thick plate

A composite welding and double-sided technology, which is applied in the direction of laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of high equipment cost, complicated and time-consuming operation, large welding stress and deformation, etc., to simplify the difficulty of operation, Good flow performance, good for overflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

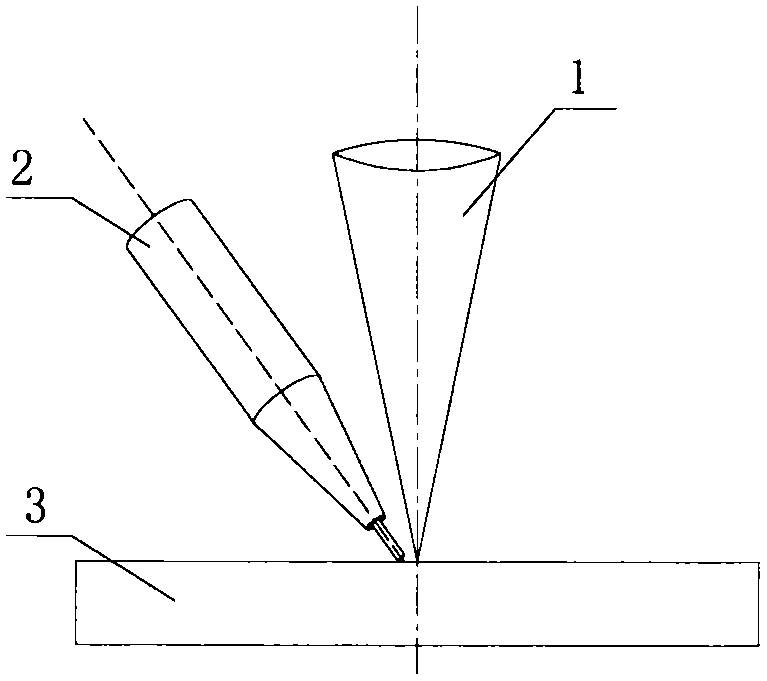

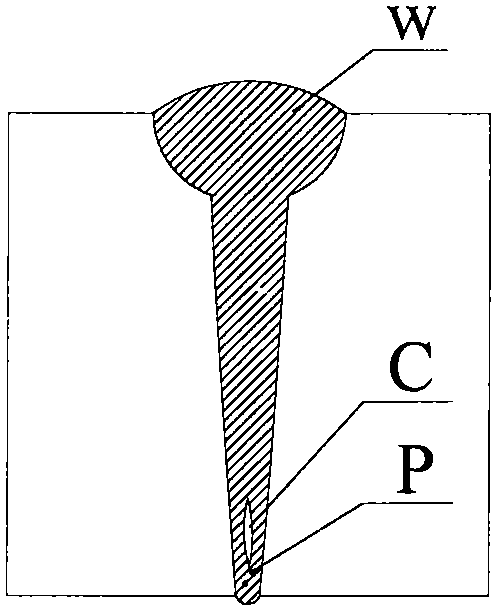

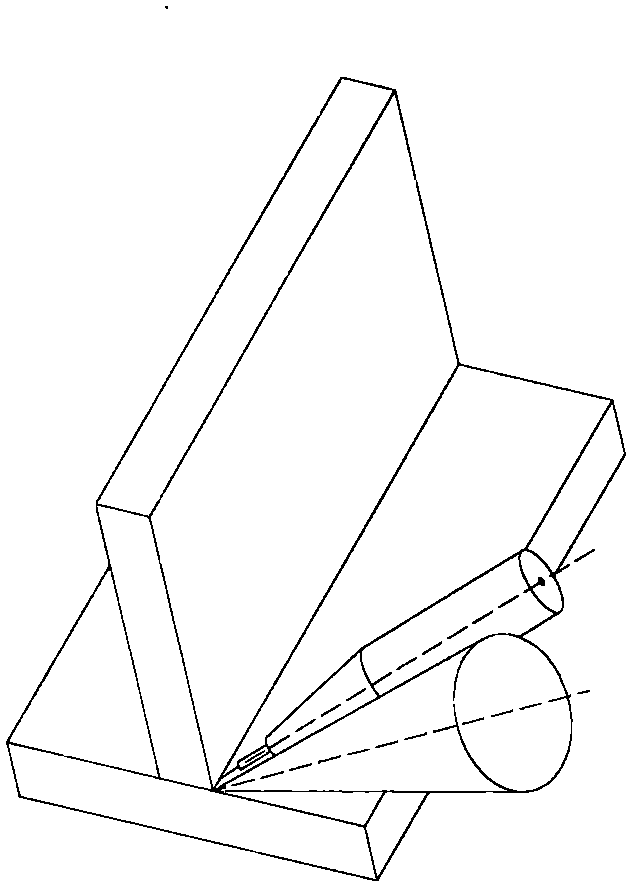

[0060] Figure 18 It is a flow chart of the laser-double-sided arc hybrid welding method, such as Figure 18 As shown, the embodiment of the present invention provides a thick plate laser-double-sided arc hybrid welding method, including:

[0061] Step 201, according to the type of welded joint, process a bevel on the part to be welded of the thick plate workpiece;

[0062] Step 202, fixing the thick plate workpiece and cleaning the part to be welded and the groove;

[0063] Step 203, a laser beam and a first welding torch are arranged on one side of the welding joint, the optical axis of the laser beam forms a first included angle of 30° to 45° with the central axis of the first welding torch; There is a predetermined distance between the incident point of the laser beam on the part to be welded and the welding wire end of the first welding torch; on the other side of the welding joint, a second welding torch is arranged in mirror image relative to the first welding torch; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com