Welding tool for induction soldering pipe fittings

A technology of induction brazing and welding tooling, applied in the field of welding tooling, can solve the problems that the workpiece cannot be positioned quickly and accurately, cannot meet the performance requirements, affect the welding quality and welding efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

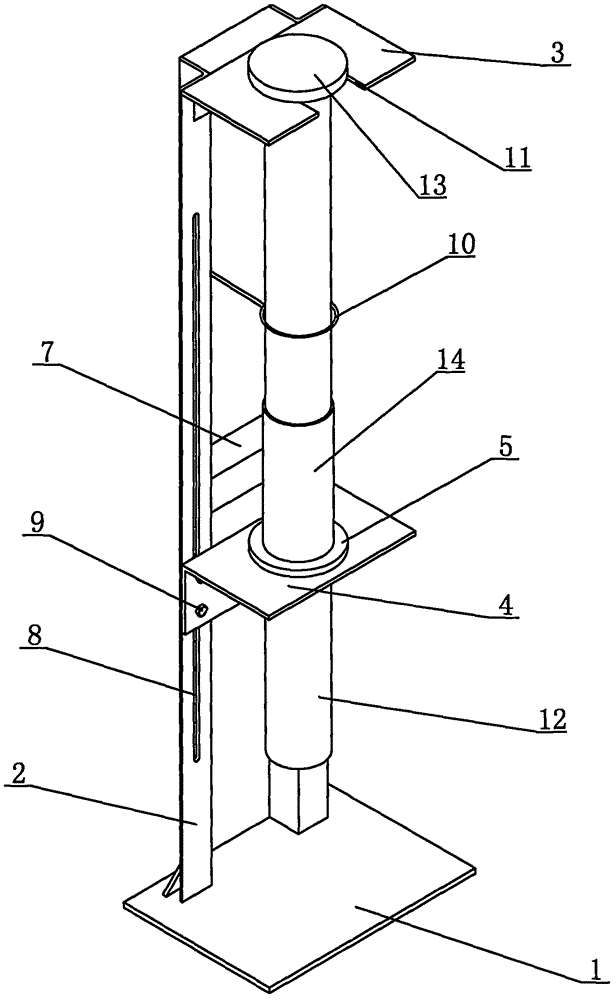

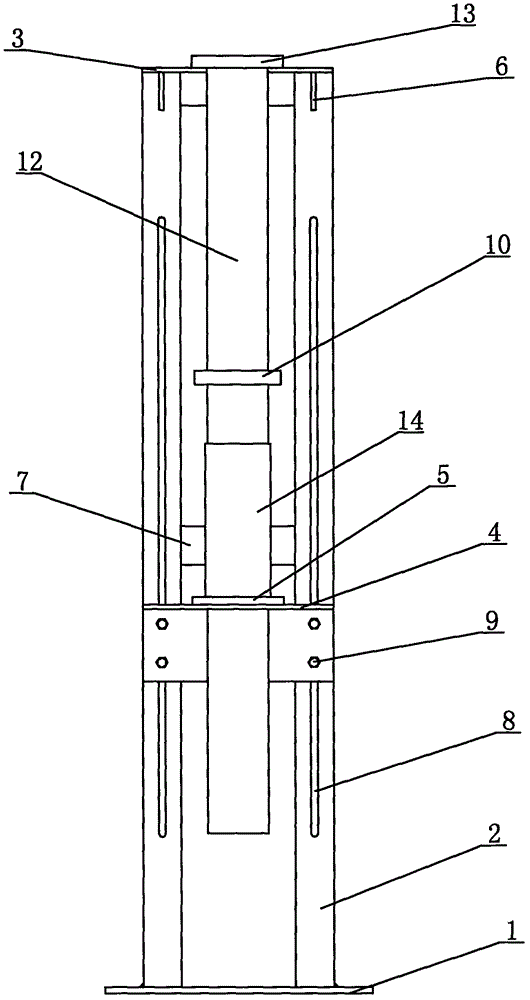

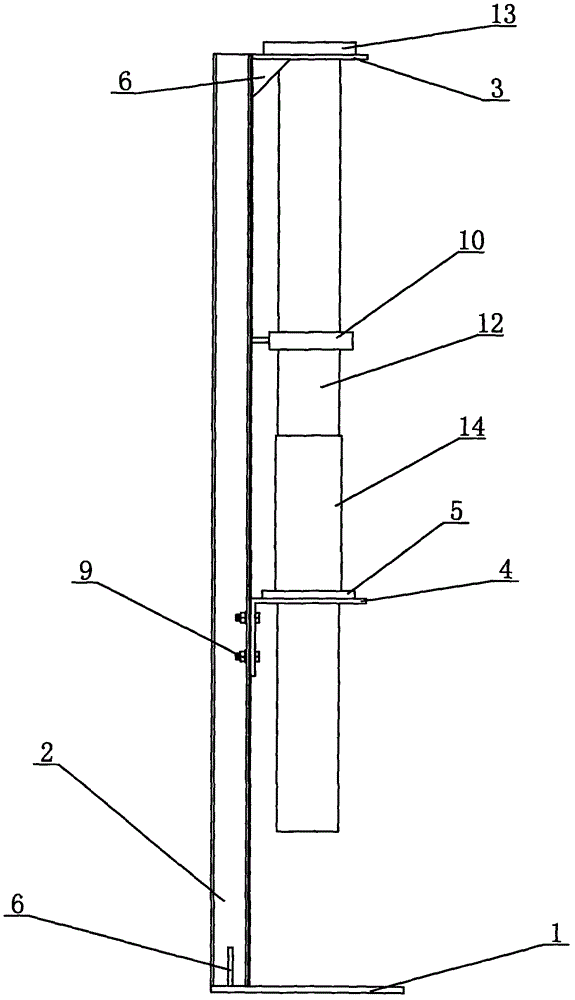

[0018] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

[0019] see Figure 1 to Figure 4 As shown, in this embodiment, a welding tool for induction brazing pipe fittings includes a bottom plate 1, two uprights 2, a pallet 3, a lifting platform 4 and a limit flange 5, and the two uprights 2 are in a vertical direction. The upper side is fixed on the bottom plate 1 in parallel and spaced apart, and a reinforcing rib plate 6 is welded between the bottoms of the two uprights 2 and the bottom plate 1, and a number of reinforcing bars 7 are connected between the two uprights 2. , the support plate 3 is fixed on the top of the two uprights 2 , and a reinforcing rib plate 6 is welded between the support plate 3 and the two uprights 2 . The two uprights 2 are made of angle steel of 50mm×50mm, and an oblong hole 8 is provided on the plane along the height direction. The lifting p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com