Runner plugging device for water-cooling die casting

A plugging device and water-cooled die-casting technology, applied in the field of metallurgical casting equipment, can solve unfavorable casting cleaning and transfer problems, achieve smooth cleaning and transfer operations, and avoid the formation of steel columns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

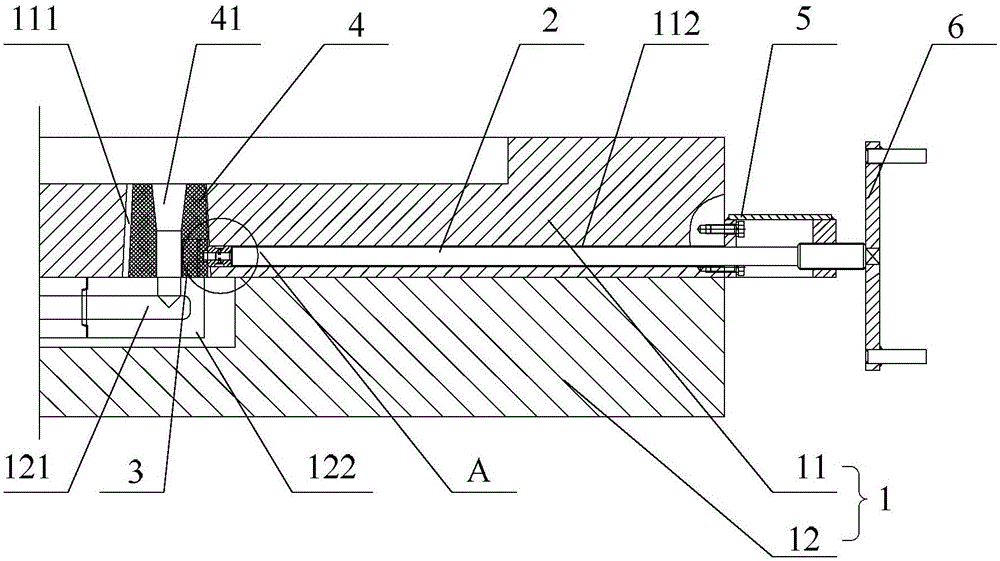

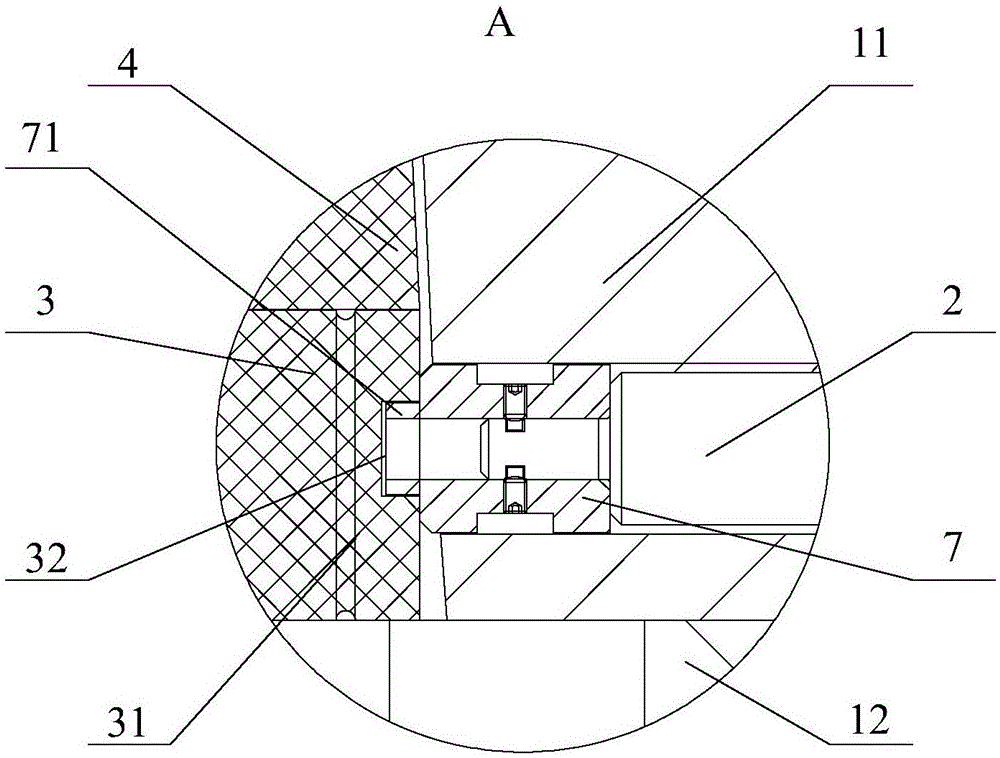

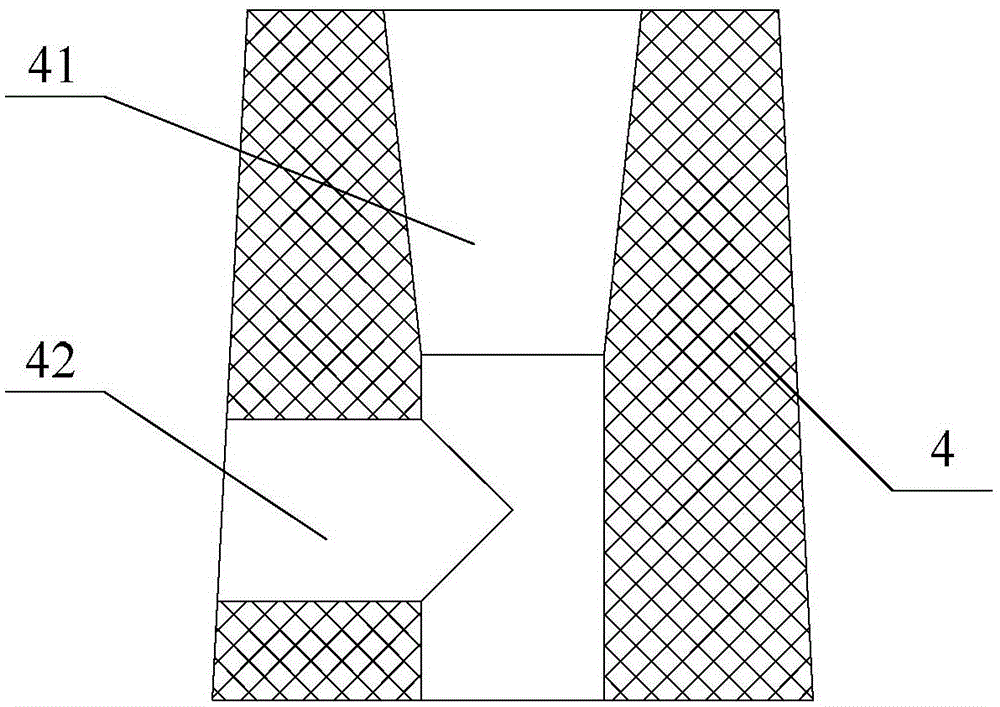

[0024] like figure 1 As shown, the present invention provides a runner sealing device for water-cooled die casting, which is arranged on the chassis 1, and the pouring surface of the chassis 1 is provided with a vertical runner 111 communicating with the mold, and the chassis 1 is provided with a vertical sprue 111 connected to the casting mold. The runner 111 seals the connected runner 121, the runner 121 is made of heat insulating material, and the side of the chassis 1 is provided with an installation channel 112 along the direction perpendicular to the vertical runner 111, and the installation channel 112 and the vertical runner 111 is connected, and the runner sealing device includes: ejector rod 2 and plug 3, wherein, ej...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com