Movable V-shaped thrust rod sealing cover withholding machine

A thrust rod, mobile technology, applied in the field of V-type thrust rod processing equipment, can solve the problems of loss of performance, large damage to the upper ball seat shell, poor design reliability, etc., to reduce labor intensity, realize process flow, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

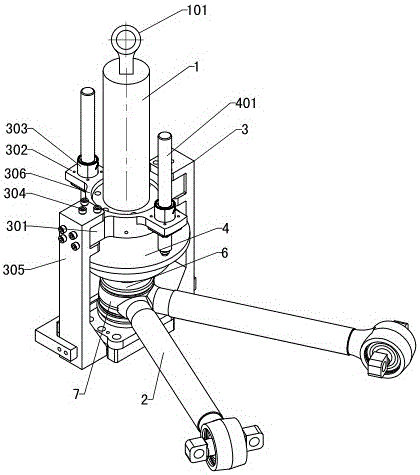

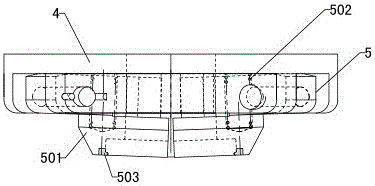

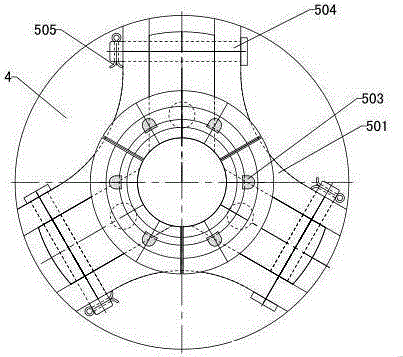

[0030] Figure 1~3 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~3 The present invention will be further described.

[0031] Refer to attached figure 1 : Movable V-shaped thrust rod sealing cover crimping machine, including hydraulic cylinder 1 and end cover riveting tool, placed vertically with the power output end facing down, the end cover riveting tool connected to the bottom of hydraulic cylinder 1, and end cover riveting tool It includes a fixing mechanism 3 and a down-press riveting mechanism, the power output end is positioned by the fixing mechanism 3 erected on both sides, and the end cover 6 of the V-shaped thrust rod 2 is pressed and riveted on it by the down-press riveting mechanism. The top of the upper ball seat 7; the inner side of the lower part of the lower pressure riveting mechanism and the contact end surface of the upper ball seat 7 are provided with multiple elastic clamping riveting points. The top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com