Sleeve rail type electric attachment lifting scaffold

A technology attached to lifting and electric lifting mechanisms, applied in the field of scaffolding, can solve problems such as incomplete anti-tilt and anti-fall functions, insufficient strength, rigidity, overturning chains, hinged chains, etc., to achieve safe and reliable anti-fall functions, compact and reasonable structure , The effect of stable lifting and lowering of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

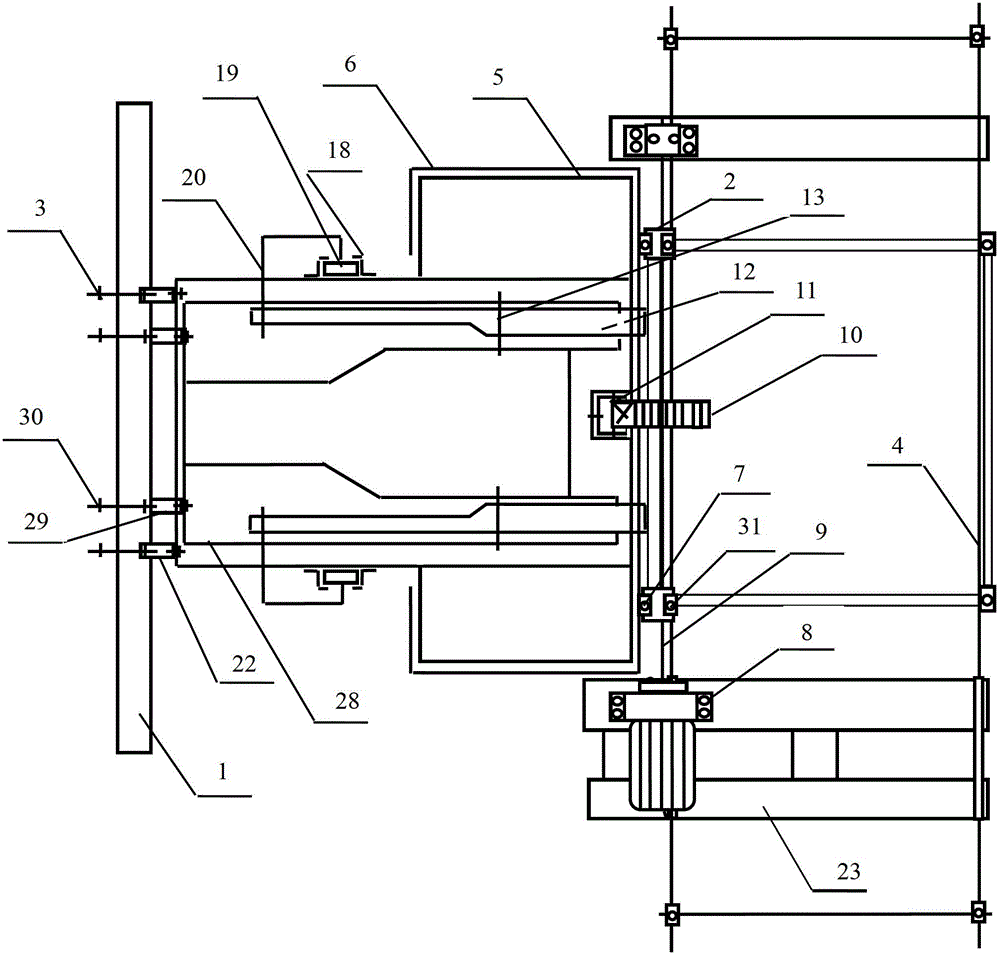

[0033] see figure 1 , figure 2 and Figure 2C , the structural form of the electric lifting mechanism provided in the rail-type electric attachment lifting scaffold of this embodiment is:

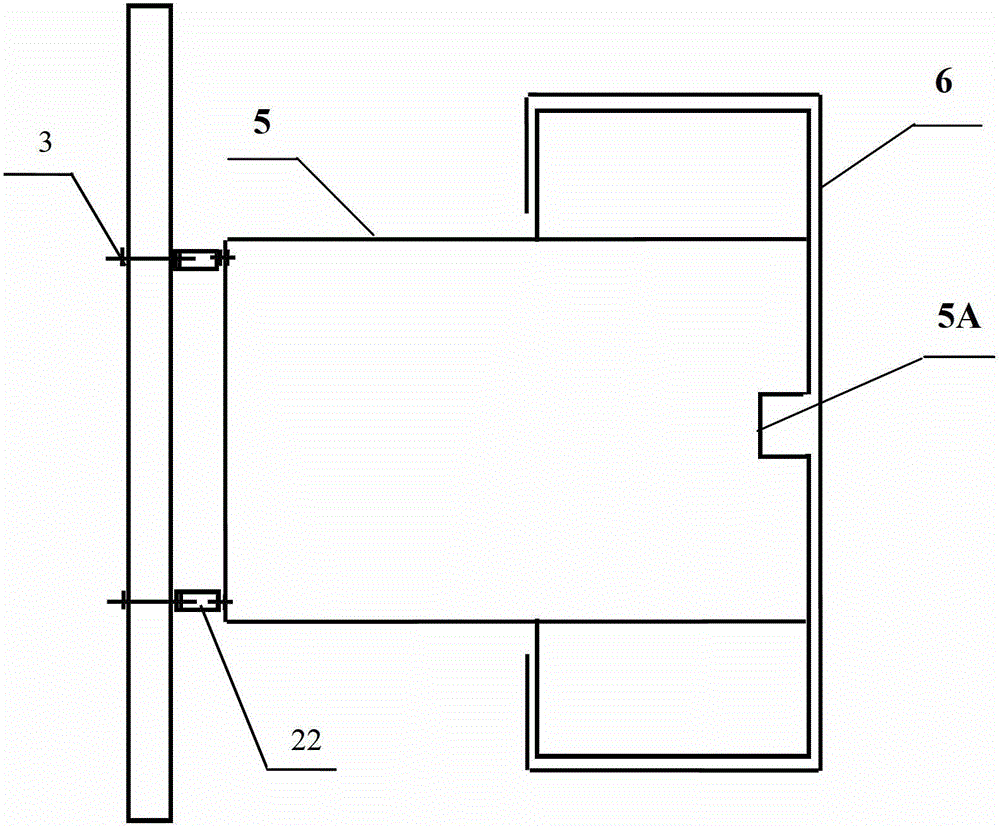

[0034] The frame body lifting and sliding cover groove 6 is sleeved on the vertical guide rail frame 5, and the frame body lifting and sliding cover groove 6 is to use the vertical guide rail frame 5 as a guide column to form a pair of vertical linear motion pairs.

[0035] The frame body 4 is fixedly connected with the frame body vertical main frame 2 through the third connecting piece 31, the frame body vertical main frame 2 is fixedly connected with the frame body lifting and sliding sleeve groove 6 through the first connecting piece 7, and the vertical guide rail frame 5 The first wall-through bolt 3 is fixedly connected to the building body beam 1 or building body column 2 by attaching the support structure 22 .

[0036] see Figure 2C and Figure 2D , the tooth post 11 that is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com