A Bending Correction Method for Shaft Parts

A technology for shaft parts and bending correction, applied in the field of machinery, can solve the problems of troublesome alignment process, low precision, and difficulty in one-time success, etc., and achieve the effect of reducing the difficulty of playing the watch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

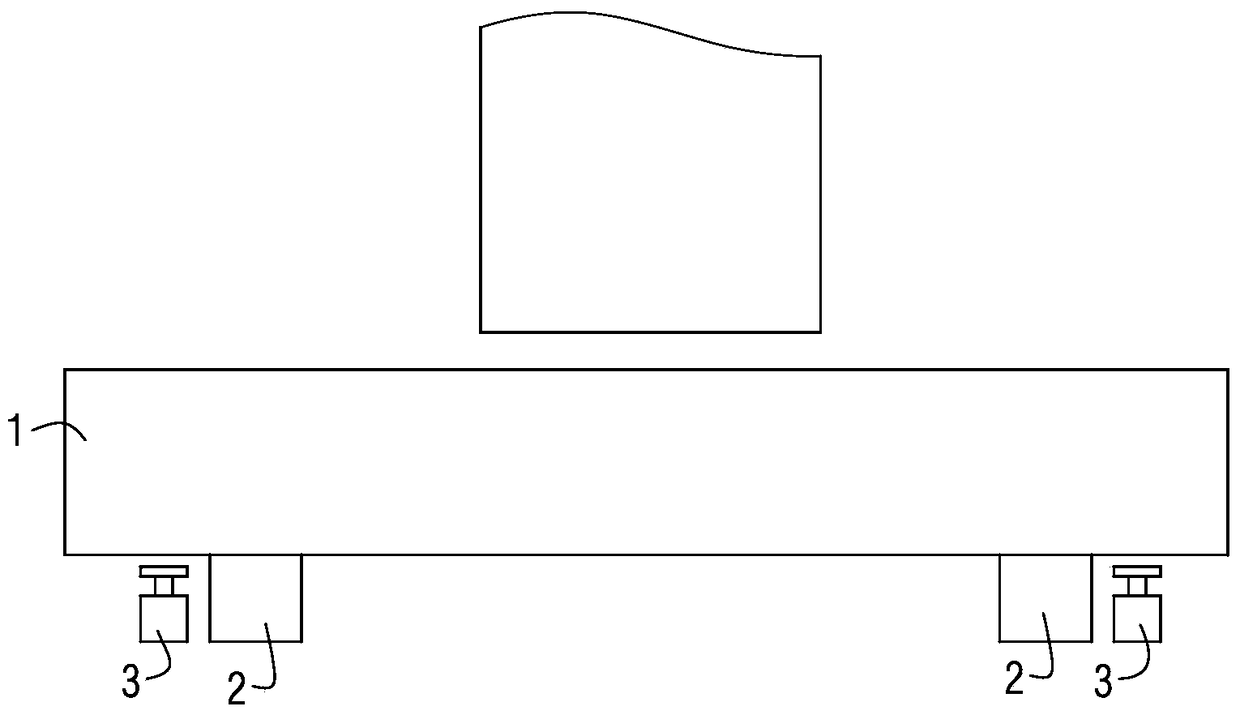

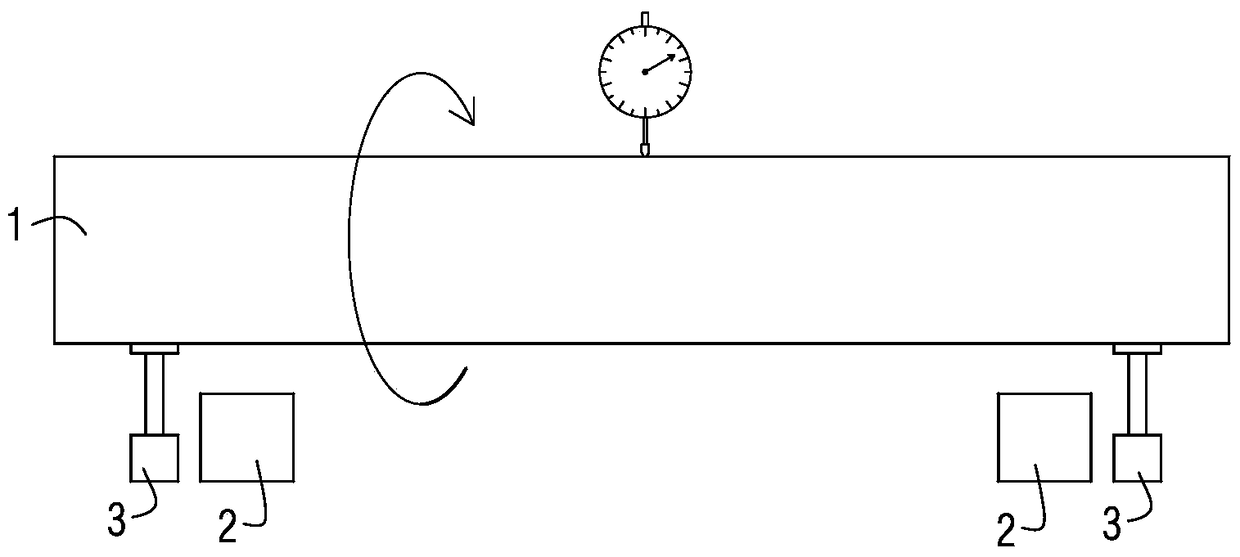

[0017] figure 1 It is a schematic diagram of the principle of the correction state of a shaft part bending correction method according to a specific embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the principle of the measurement state; image 3 for figure 1 The schematic diagram of the principle of the lifting meter device shown; Figure 4 for image 3 A partial sectional structural schematic diagram of the lifting watch device shown. see Figure 1-4 As shown, the present invention provides a bending correction method for shaft parts, which includes the following steps,

[0018] In step A, the shaft part 1 is placed on the pad 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com