Macroporous spherical composite-material catalyst for removing benzene compounds in air and preparation method

A composite material and catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as secondary pollution, achieve efficient catalytic combustion, high efficiency The effect of benzene series pollution and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

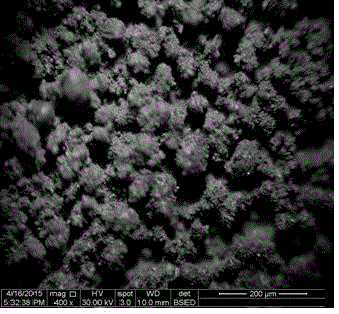

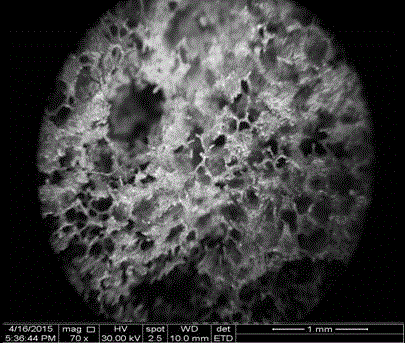

Image

Examples

Embodiment 1

[0032] Take 2 grams of chloropalladium acid and dissolve it in 100mL of water. While stirring, add 100g of D301 macroporous weakly basic styrene-based anion exchange resin and stir evenly. Rinse until no chloride ions in the filtrate can be detected with silver nitrate solution, then put the resin in a drying oven at 60°C to dry.

[0033] Al with an average particle size of 5 microns 2 o 3 12g of the powder is slurried with a 3% aqueous solution of methyl cellulose, ground into a uniform slurry with an agglomerated particle size of less than 30 microns with a three-roller mill, and the above-mentioned macroporous resin that has adsorbed precious metals is used for slurry roll coating and dried 30 minutes.

[0034] Use nano palladium black 0.8g to carry out rolling on Al 2 o 3 The surface layer of the film was dried at 180°C for 12 hours. Put the above resin into a muffle furnace heated to 700°C to burn and volatilize for 1-8 hours, and then reduce it in a hydrogen atmosph...

Embodiment 2

[0036] Take 2.2 grams of chloroplatinic acid and dissolve it in 100 mL of water. Under stirring, add 100 g of D301 macroporous weakly basic styrene-based anion exchange resin and stir evenly. The solution changes from orange to colorless and transparent. Separate the solid and liquid, and use Rinse with a small amount of water until no chloride ions are detected in the filtrate with silver nitrate solution, then put the resin into a drying oven at 60°C to dry.

[0037] CeO with an average particle size of 1 μm 2 -Al 2 o 3 12g of the powder is slurried with a 3% aqueous solution of methyl cellulose, ground into a uniform slurry with an agglomerated particle size of less than 30 microns with a three-roller mill, and the above-mentioned macroporous resin that has adsorbed precious metals is used for slurry roll coating and dried 30 minutes.

[0038] Use nano-platinum black 0.8g to carry out rolling on Al 2 o 3 The surface layer of the film was dried at 180°C for 12 hours. P...

Embodiment 3

[0040] Get 1.245 grams of chloroplatinic acid, 0.936 gram of chloropalladic acid and dissolve it in a certain amount of water. Under stirring, add 100 g of D301 macroporous weakly basic styrene-based anion exchange resin and stir evenly. The solution turns from orange red to colorless and transparent. , separate the solid and liquid, rinse with a small amount of water until no chloride ions in the filtrate can be detected with silver nitrate solution, and then put the resin in a drying oven at 60°C to dry.

[0041] CeO with an average particle size of 1 μm 2 -Al 2 o 3 12g of the powder is made into a slurry with an aqueous solution of methyl cellulose (methyl cellulose 3%), and ground into a uniform slurry with an agglomerated particle size of less than 30 microns with a three-roll mill, and the above-mentioned macroporous resin that has adsorbed precious metals is subjected to slurry rolling Apply and let dry for 30 minutes.

[0042] Use 0.400g of nano-platinum black and 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com