Composite material for electrodes, method for producing same, and secondary battery

A composite material and secondary battery technology, applied in non-aqueous electrolyte batteries, lithium batteries, battery electrodes, etc., can solve the problems of narrowing the selection range of negative electrodes and low electron conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

[0077] 3. Example 2 (Secondary Batteries Relating to the First to Seventh Aspects of the Present Disclosure)

[0078] 4. Example 3 (variation of Example 2)

[0079] 5. Example 4 (variation of Example 3)

[0080] 6. Example 5 (another variant of Example 3)

[0081] 7. Example 6 (another variant of Example 3) and others

[0082][Explanation of overall matters relating to the electrode composite material, the method for producing the composite material, and the secondary battery of the first aspect to the seventh aspect of the present disclosure]

[0083] In the following description, the electrode composite material related to the first aspect to the seventh aspect of the present disclosure, the method for preparing the electrode composite material related to the first aspect to the seventh aspect of the present disclosure, and the first aspect related to the present disclosure The secondary batteries through the seventh aspect may be collectively referred to simply as "the p...

example 1

[0190] Example 1 relates to the composite material for electrodes and the method for preparing the composite material according to the first aspect to the seventh aspect of the present disclosure.

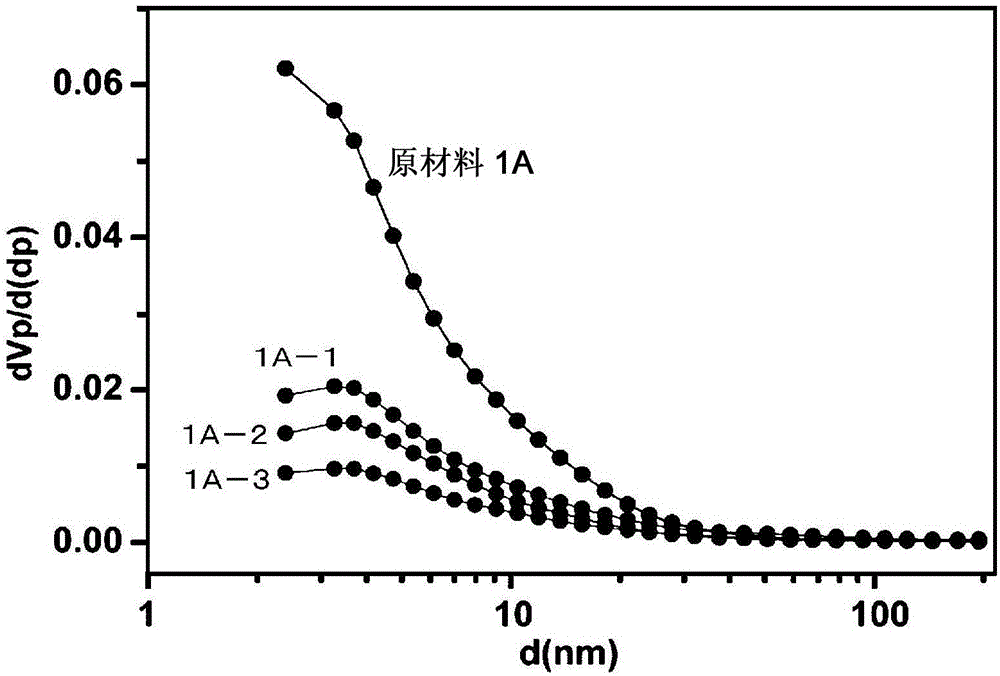

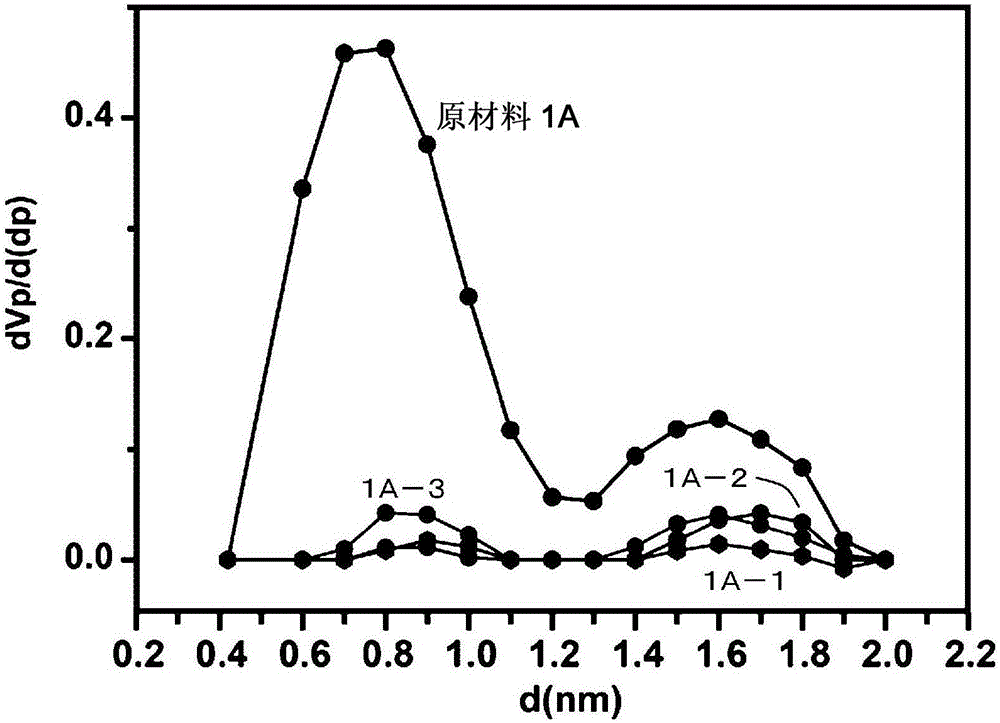

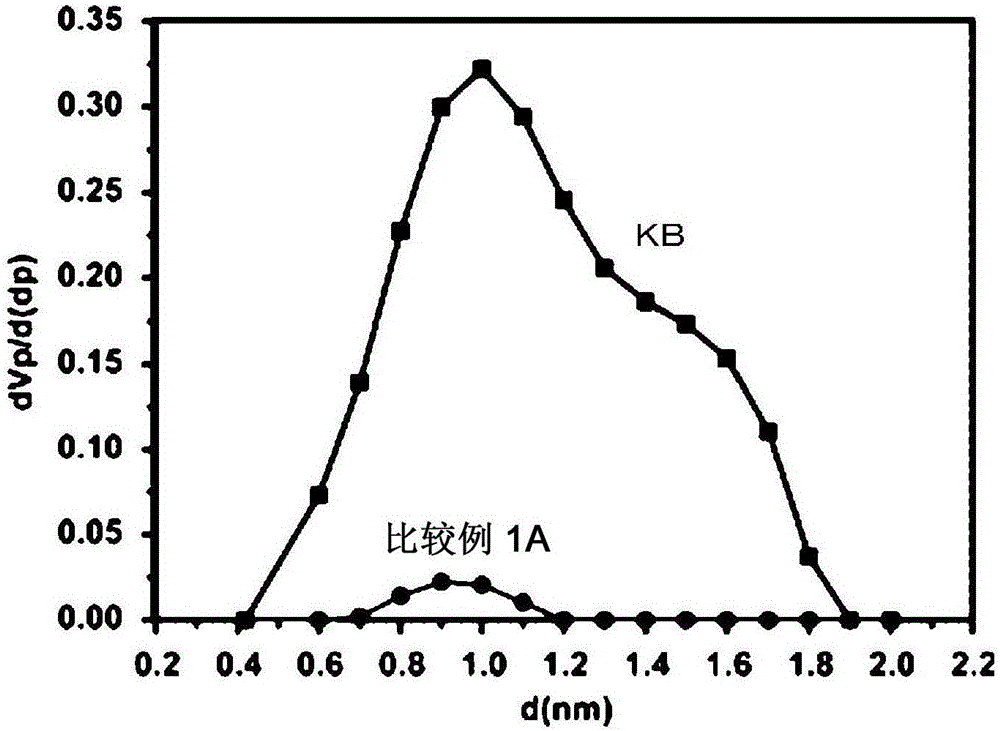

[0191] Specifically, the composite material for electrodes in Example 1 includes a plant-derived porous carbon material and lithium sulfide (Li sulfide) supported on pores that the porous carbon material has. x S, precondition: 0PC 0.1cm 3 / g or greater, and the pore volume MP of the electrode composite material according to the MP method 0 less than 0.1cm 3 / g (relating to the composite material for electrodes of the first aspect of the present specification). Alternatively, the pore volume MP of the electrode composite according to the MP method 0 less than 0.1cm 3 / g, and after washing with water, the pore volume MP of the electrode composite material according to the MP method 1 Greater than the pore volume MP 0 (The composite material for electrodes relating to the secon...

example 3

[0283] Example 3 is a variant of Example 2. In Example 2, the composite material for electrodes in Example 1A-2 was used. On the other hand, in Example 3, a positive electrode of a secondary battery was prepared using the composite material for electrodes (lithium sulfide porous carbon composite material) in Example 1A-3 and other materials, and a secondary battery was further prepared. Specifically, slurries with blends indicated in Table 12 below were prepared. Then, a lithium sulfide secondary battery formed from a 2016-type coin battery was assembled by the same method as used in Example 2 using the blend (cathode material and active material for the cathode) having the composition indicated in Table 12.

[0284] [Table 12] The electrode of the secondary battery in the example 3

[0285]

[0286]

[0287] As described in Table 13 below, the conditions for the charge-discharge test of the lithium sulfide secondary battery were set. At the same time, the discharge c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com