Method for draining an oil well and system for implementing said method

A technology for oil wells and excitation systems, applied in the field of electrical systems, can solve problems such as system failure, high cost, and impossibility to ensure safety, and achieve the effect of avoiding costs and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

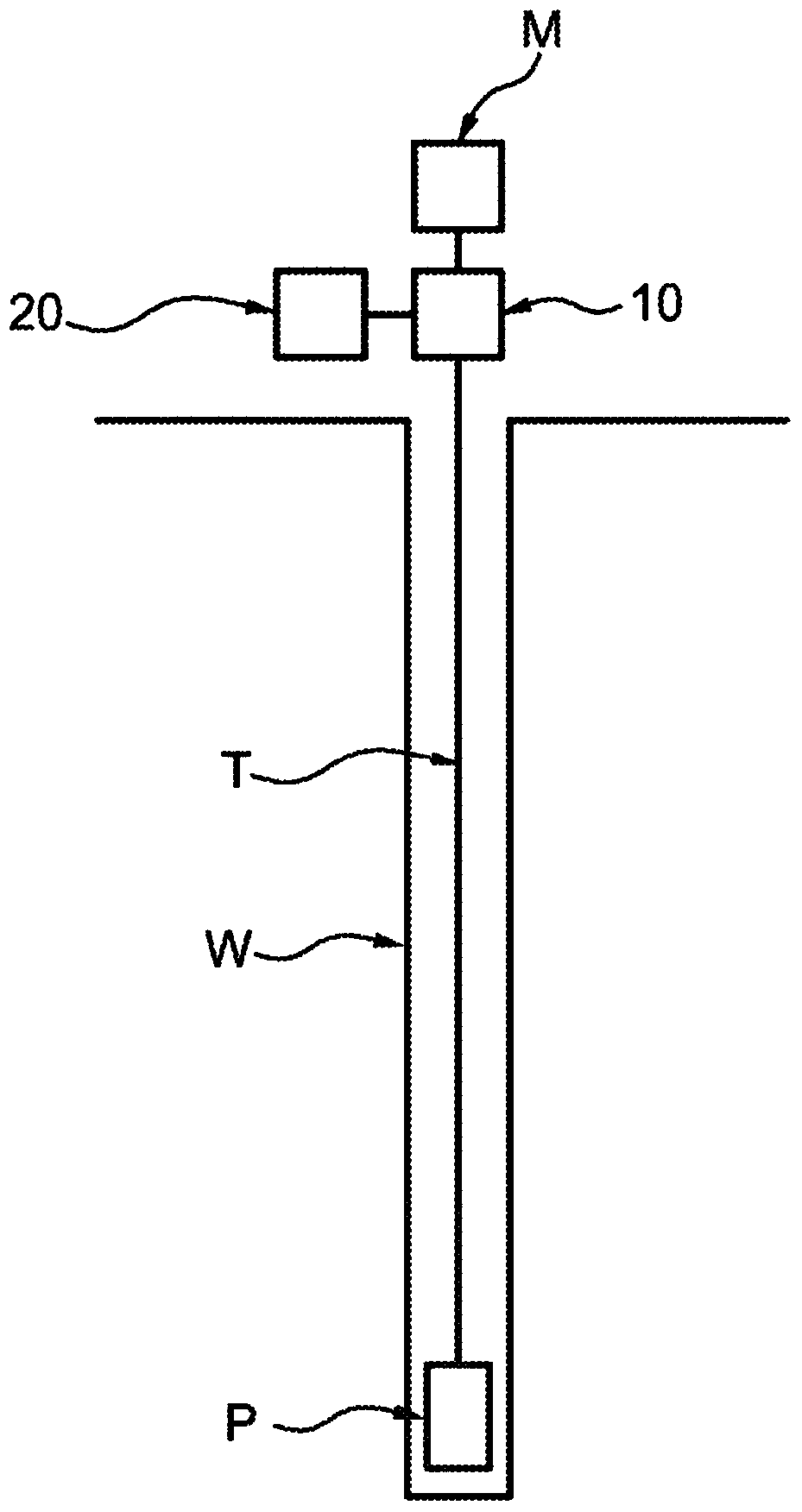

[0043] figure 1 An oil well W is schematically shown, in the bottom of which is submerged a pump P, preferably a progressive cavity pump, driven from the surface by a motor M via a drive rod T and a gearbox 10 .

[0044] According to the invention, a system 20 for decelerating the drive rod T is provided to avoid a runaway installation in case of changes in the operating conditions of the installation, especially when the motor M is stopped, and to ensure that the installation is performed in good safety conditions ( Especially when the maximum temperature is reached) the well W is drained.

[0045] According to the invention, the reduction system 20 comprises an eddy current reducer 25 .

[0046] deceleration system

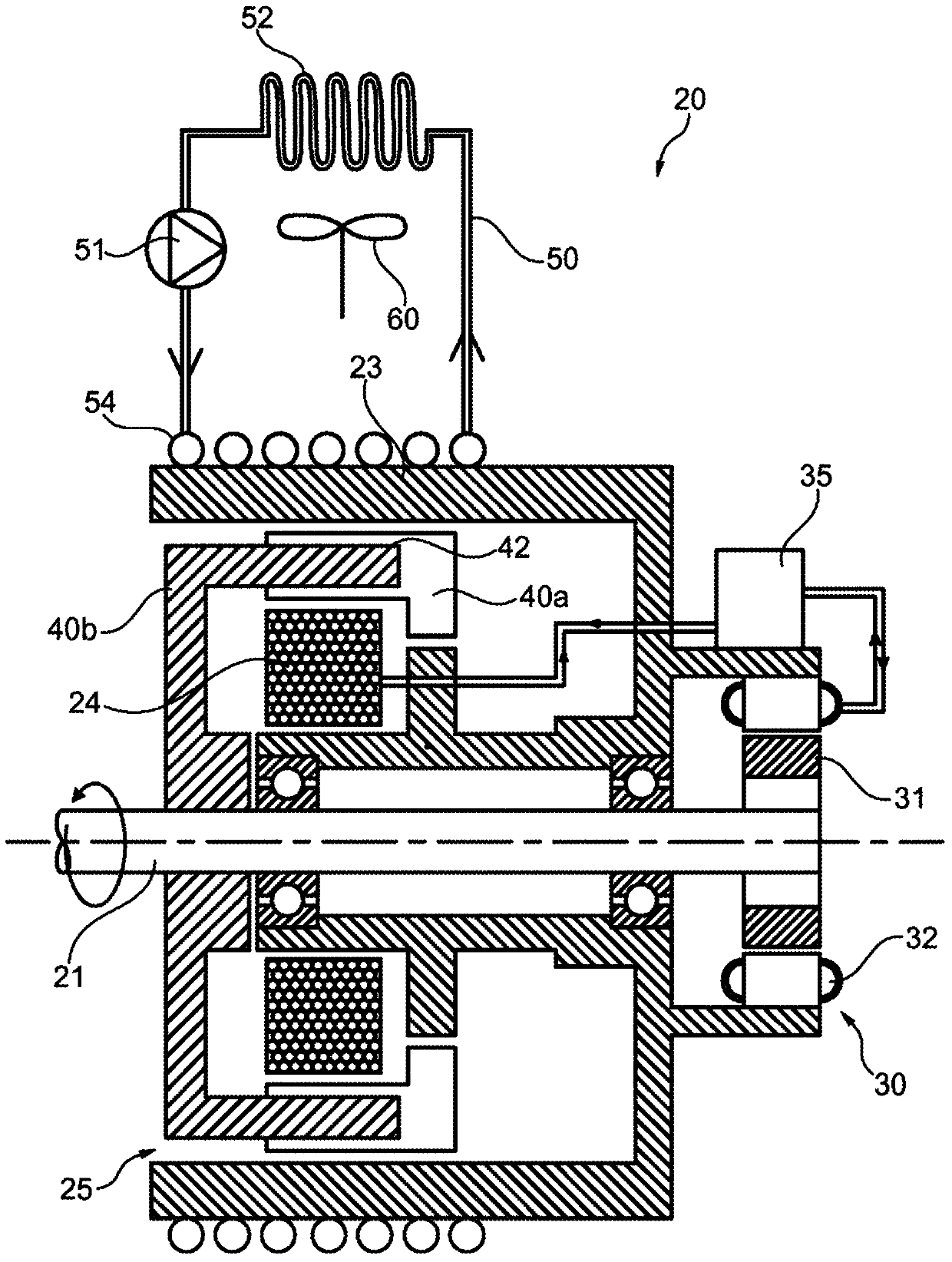

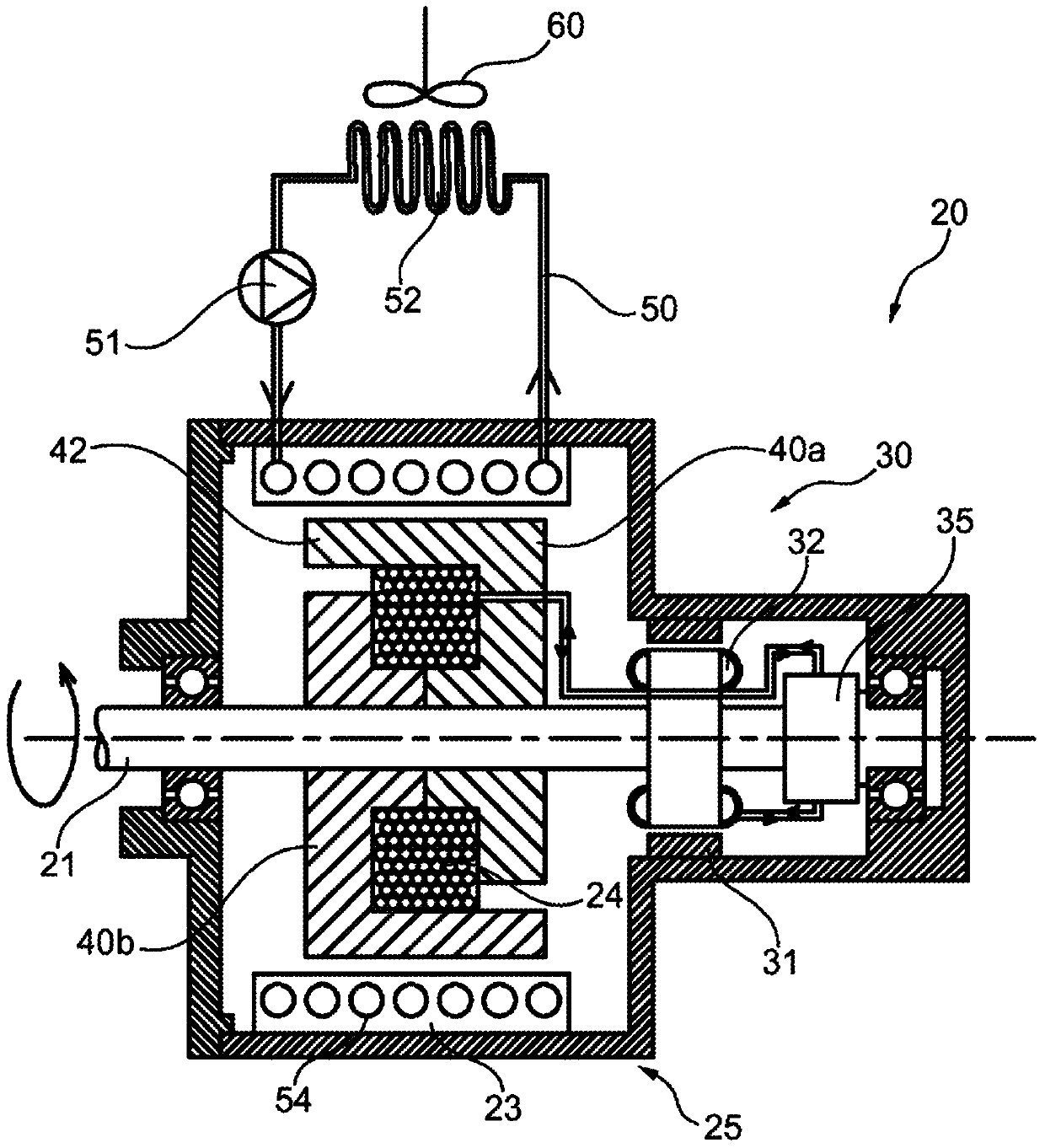

[0047] The reduction system 20 can have different configurations, in Figure 2 to Figure 5 An example of a reduction system has been given schematically in .

[0048] In these figures, the drive shaft 21 of the reduction system 20 is very schematically repre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com