Battery pack cooling device of electric car

A technology of heat dissipation device and electric vehicle, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of low heat dissipation efficiency, low heating efficiency, large power consumption, etc., and achieves good heat dissipation performance, long driving range, Low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

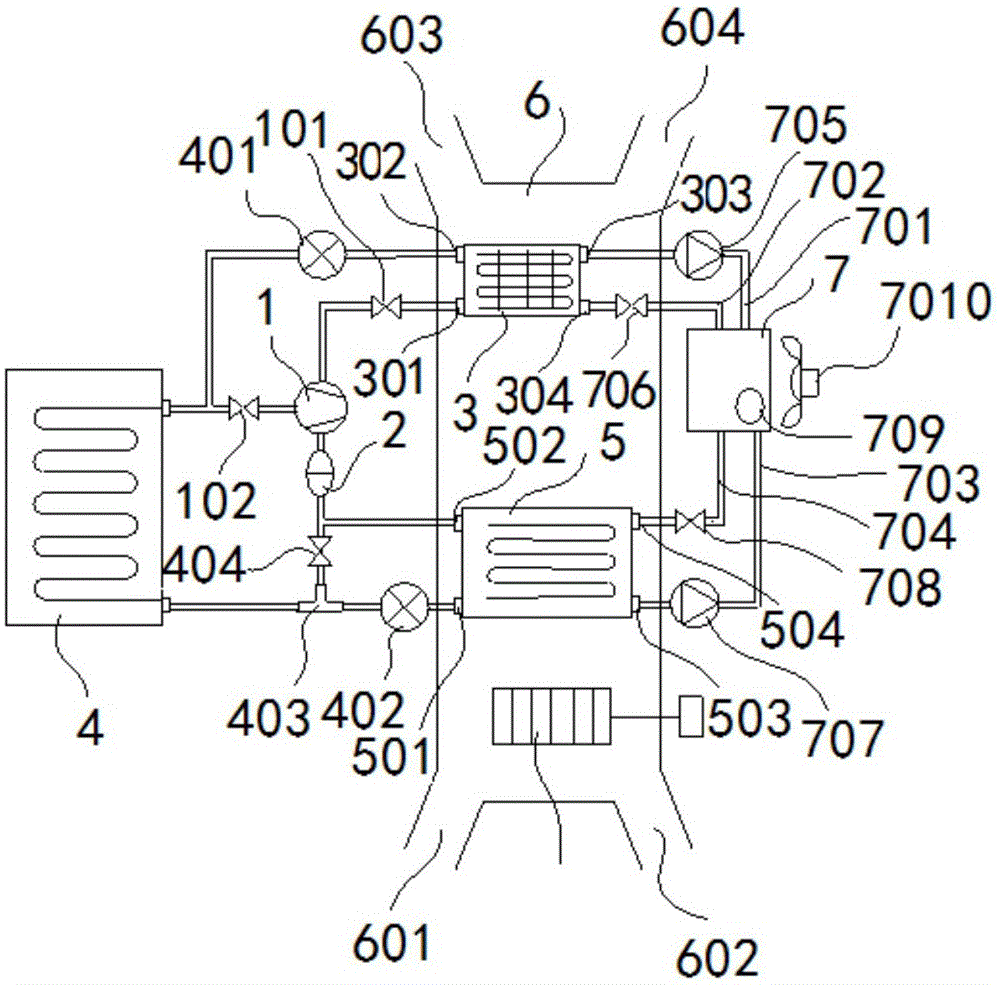

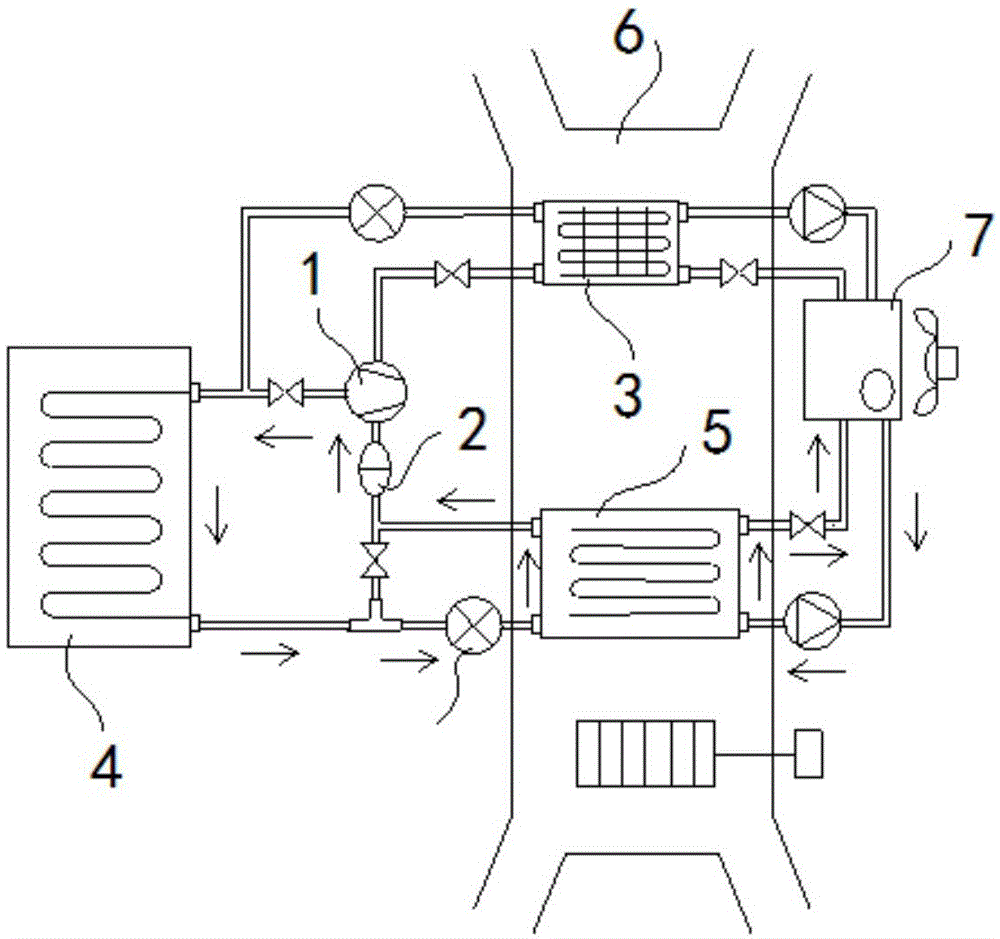

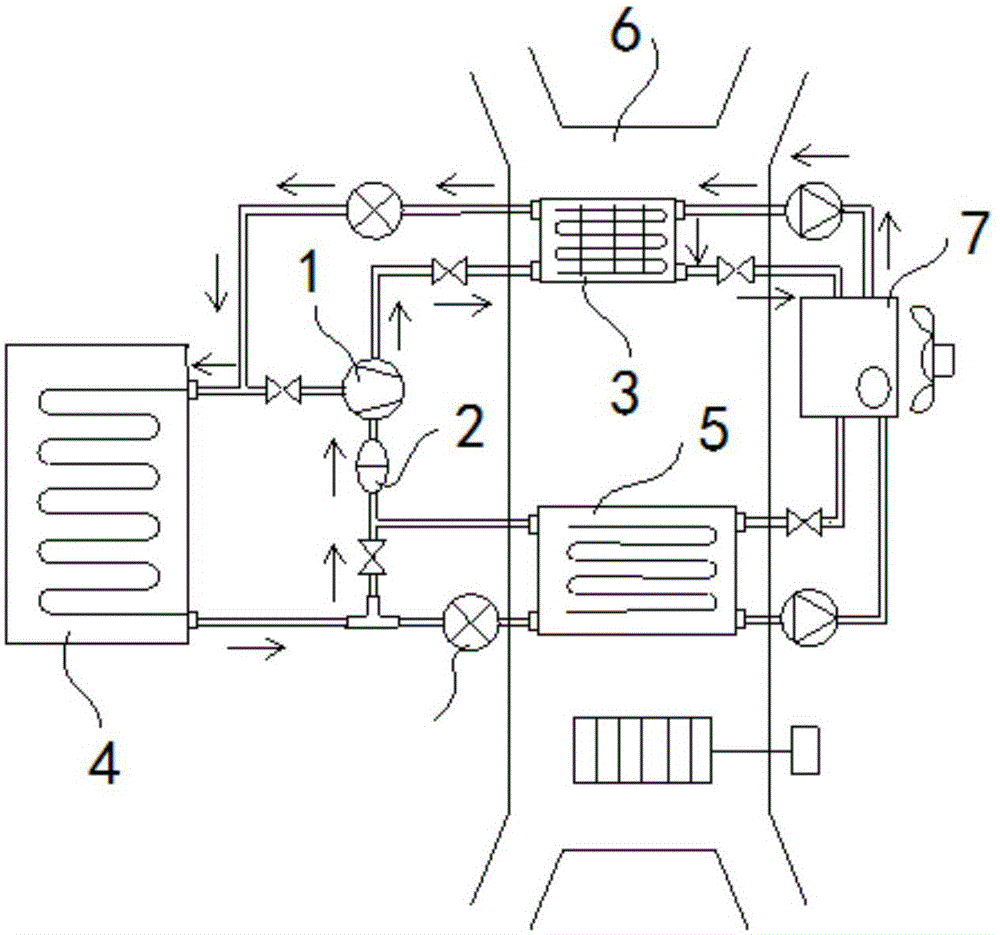

[0024] Such as figure 1 As shown, the electric vehicle battery pack cooling device of the present invention includes: compressor 1, gas-liquid separator 2, interior condenser 3, exterior heat exchanger 4, interior heat exchanger 5, air duct 6, battery Group cooling device 7.

[0025] The outlet of the compressor 1 is respectively connected to the first inlet 301 of the in-vehicle condenser 3 and the inlet of the external heat exchanger 4 through pipelines, and the first outlet 302 of the in-vehicle condenser 3 is connected to The inlet of the outside heat exchanger 4 and the outlet of the outside heat exchanger 4 are respectively connected to the inlet of the gas-liquid separator 2 and the second inlet 501 of the inside heat exchanger 5 through pipelines. The second outlet 502 of the in-vehicle heat exchanger 5 is connected to the inlet of the gas-liquid separator 2 through a pipeline, and the outlet of the gas-liquid separator 2 is connected to the inlet of the compressor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com