Small-sized electric control gasoline engine touching-type HMI calibration method based on CAN bus

A technology of CAN bus and calibration method, which is applied in the field of touch-type HMI calibration system for small electronically controlled gasoline engines, and can solve problems such as non-general small gasoline engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The object of the present invention is accomplished through the following technical solutions:

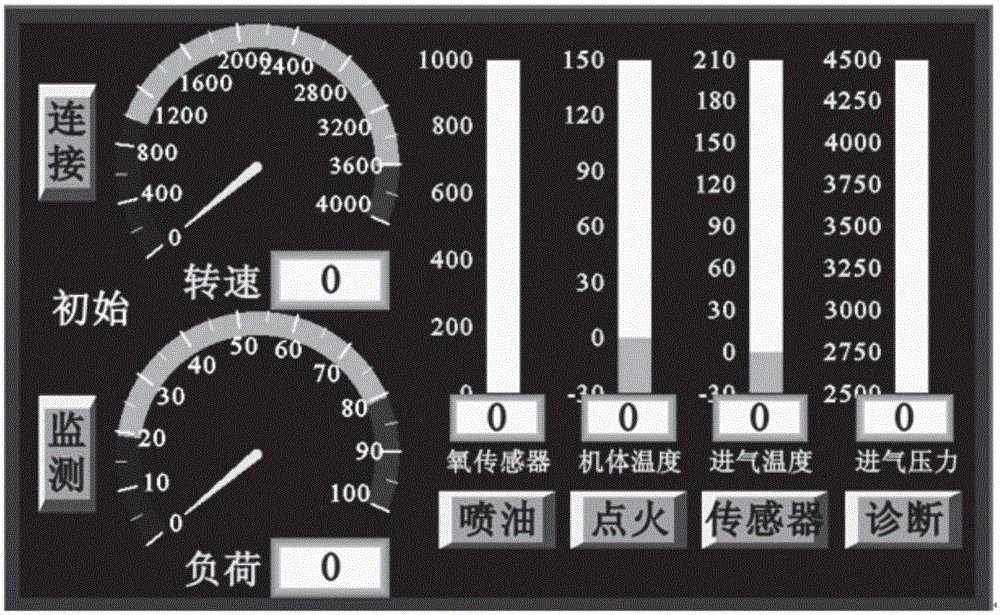

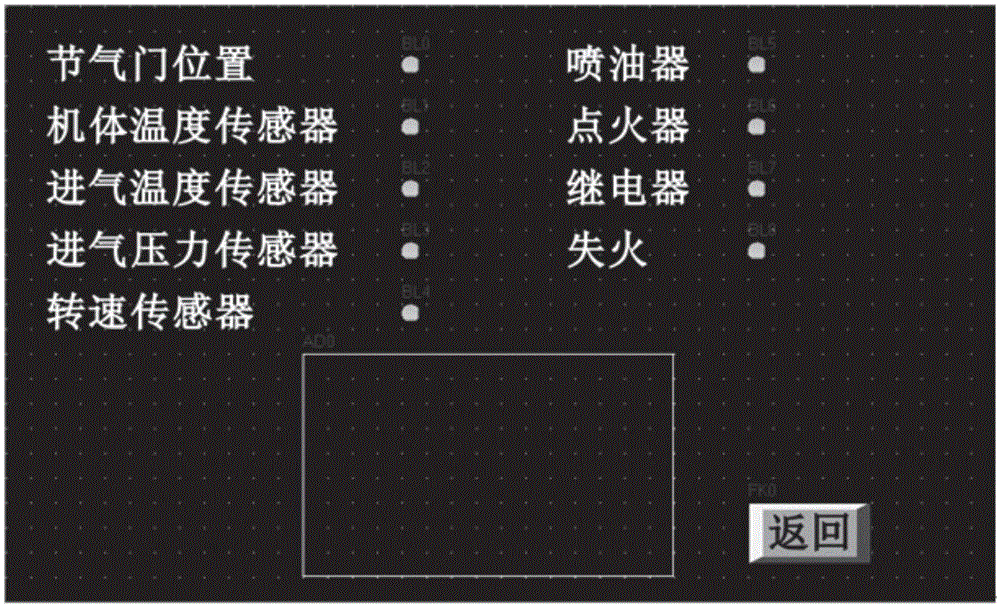

[0042] The development content of the calibration system includes two parts: the calibration software of the upper computer and the ECU calibration module of the lower computer. On the software and hardware platform of the electronic control system of the small gasoline engine, through the "bridge" of the upper and lower computers——CAN bus, real-time and reliable data communication tasks. The upper computer calibration software is developed on the basis of touch-type human-computer interaction equipment (HMI), including three sub-modules of front-end interface, data management and communication control. Among them, the calibration interface provides human-computer interactive access and responds to user operations, data management optimizes global variables and establishes project files, and communication control rationally organizes, sends and receives data, which are the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com