An ammeter terminal block

A terminal block and electric meter technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve problems such as low efficiency, cluttered and complex wiring harnesses, etc., and achieve the effect of reducing time consumption and improving product reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

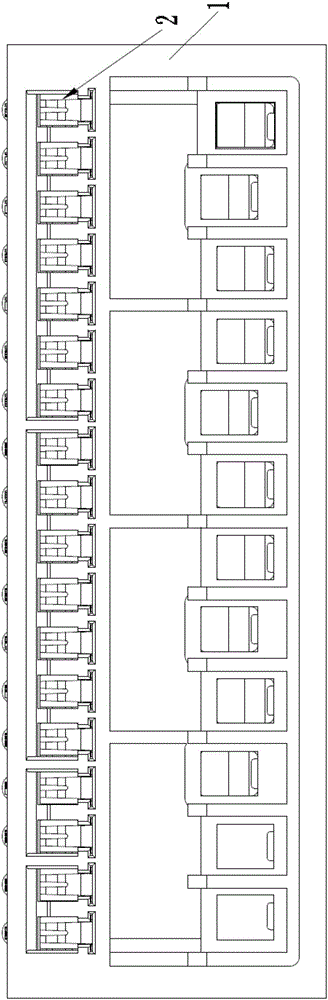

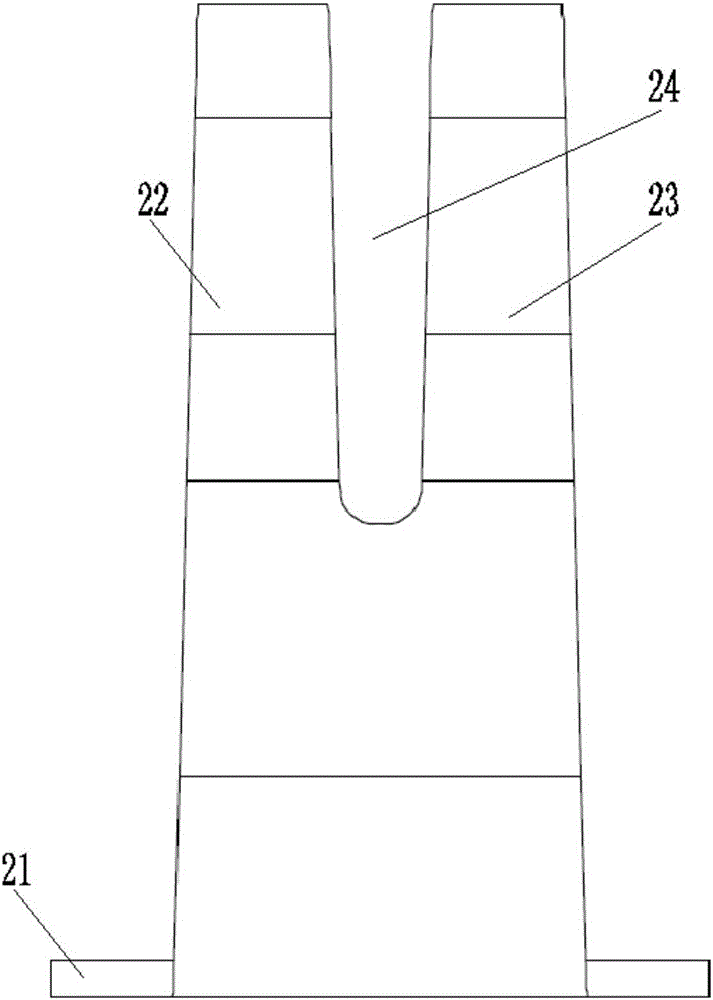

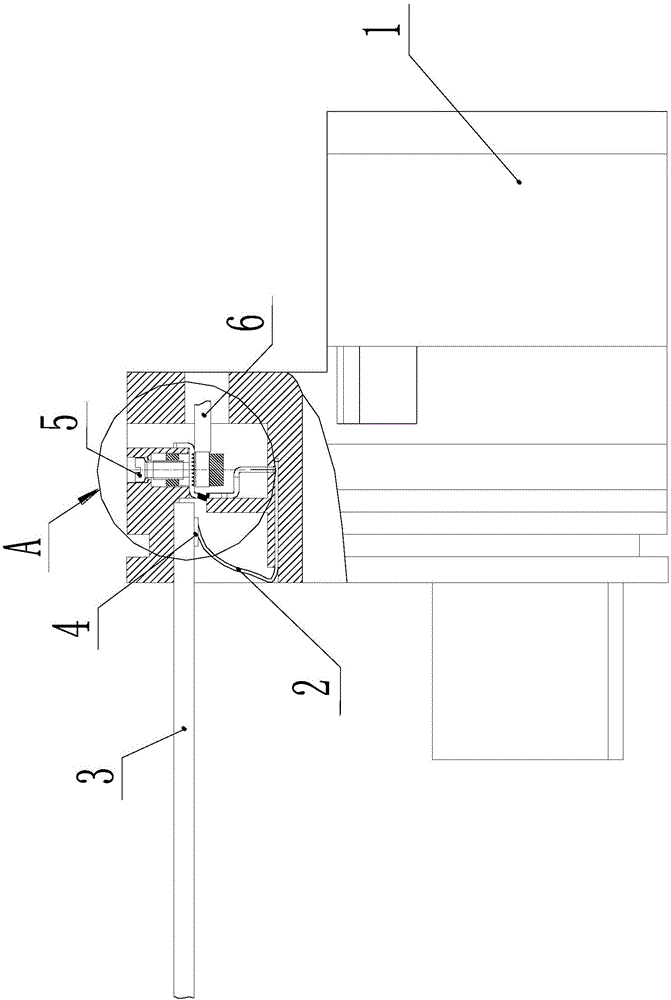

[0028] Such as Figure 1-5 As shown, it shows a specific embodiment of the present invention, as shown in the figure, the present invention is an ammeter terminal block, which is used to connect with a PCB board 3; it includes a terminal block body 1 and a double contact shrapnel 2; the terminal There is a mounting groove on the body of the terminal, and the lower end of the double-contact shrapnel is fixedly installed in the mounting groove on the body of the terminal block; pads 4 are evenly distributed on the PCB along the width direction of the PCB, correspondingly, the The double-contact shrapnel 2 are evenly distributed in the installation groove; the pads are soldered and installed on the bottom surface of the PCB; between the tank walls at the top;

[0029] As shown in the figure, the terminal block body is also provided with a mounting hole for assembling wires; a crimping frame 7 is provided in the mounting hole; Square hole 72; there is a threaded hole on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com