A micro-convective radiation cooling and heating ceiling device

A ceiling, cooling and heating technology, applied in the field of micro-convection radiation cooling and heating ceiling devices, can solve the problems of low comfort, high energy consumption and high production cost of indoor heat exchange devices, and achieves improving indoor comfort, reducing energy consumption and reducing heat transfer. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

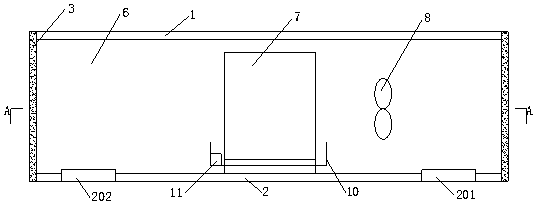

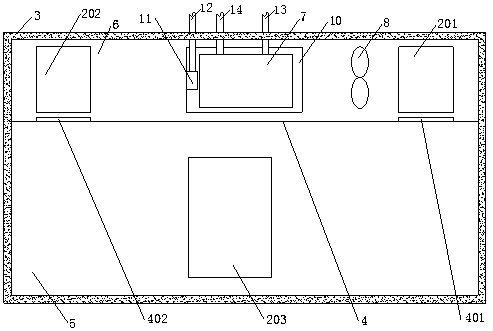

[0034] Such as figure 1 , figure 2 , Figure 5 As shown, Embodiment 1 of the present invention provides a kind of micro-convection radiation heating and cooling ceiling device, comprising:

[0035] Insulation board 1;

[0036] The ceiling board 2 arranged under the insulation board 1, the outer edge of the ceiling board 2 is connected with the outer edge of the insulation board 1 through the connector 3 to form a sealed space, and the ceiling board 2 is provided with a pair of air inlets 201 and a pair of air outlets 202;

[0037] The connecting plate 4 located in the sealed space, the upper and lower ends of the connecting plate 4 are respectively connected with the insulation board 1 and the ceiling plate 2, and the sealed space is divided into a circulation space 5 and a heat exchange space. The exchange space 6, and the connecting plate 4 is provided with a circulation air inlet 401 and a circulation air outlet 402;

[0038] The coil pipe 7 arranged in the exchange s...

Embodiment 2

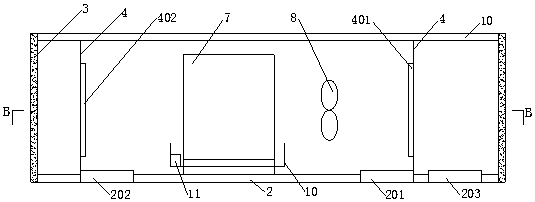

[0059] This embodiment 2 is basically the same as the above-mentioned embodiment 1, the difference is that, as image 3 , Figure 4 As shown, the connecting plate 4 of the present embodiment is in the shape of a rectangular ring, and the connecting plate 4 divides the sealed space into a rectangular exchange space 6 and an annular circulation space 5 surrounding the exchange space 6. The convection air inlet 201 The circulation air inlet 401 and the circulation air outlet 402 are symmetrically arranged on the circulation space 5 . By setting the rectangular ring-shaped connection plate 4, on the one hand, the area of the connection plate 4 is increased, that is, the contact area between the exchange space 6 and the circulation space 5 is increased, which is beneficial to the heat transfer between the exchange space 6 and the circulation space 5 directly through the connection plate 4, On the other hand, airflow passages are formed on both sides of the exchange space 6, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com