Bearing and deep-well pump transmission shaft system provided with bearing

A technology for transmission shafts and deep well pumps, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve problems such as the inability to meet the vibration reduction requirements of long transmission shafts, and avoid insufficient lubrication, The effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

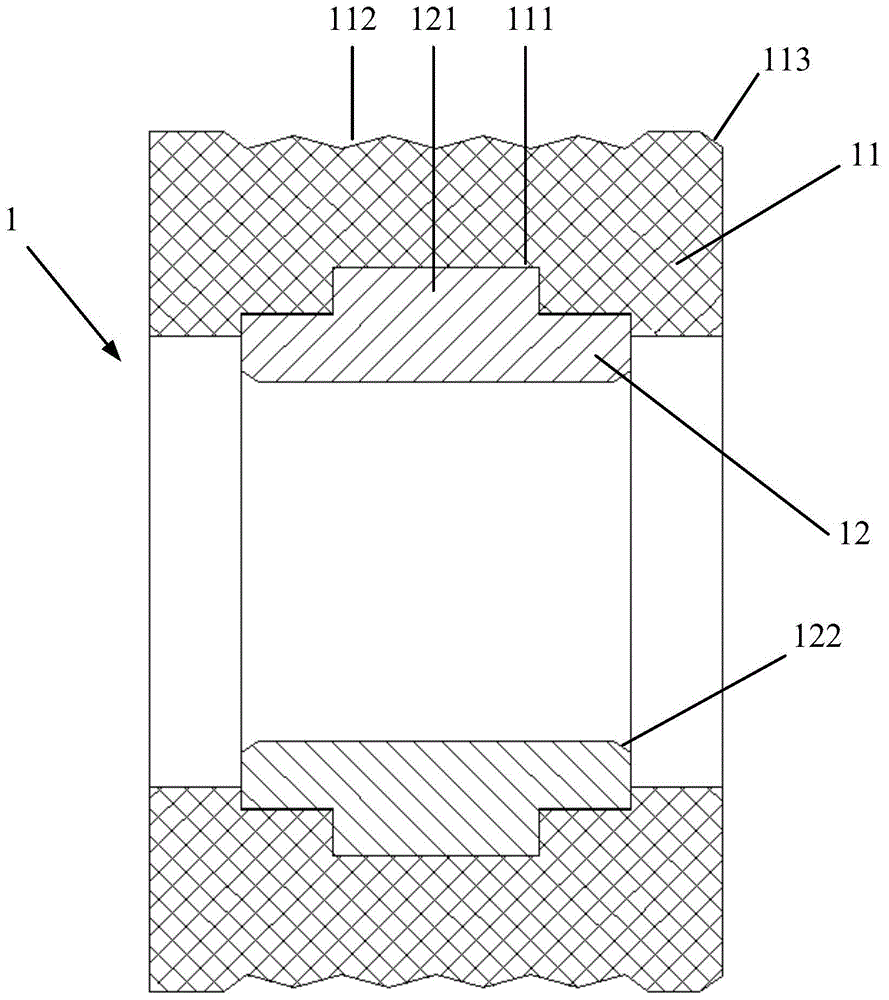

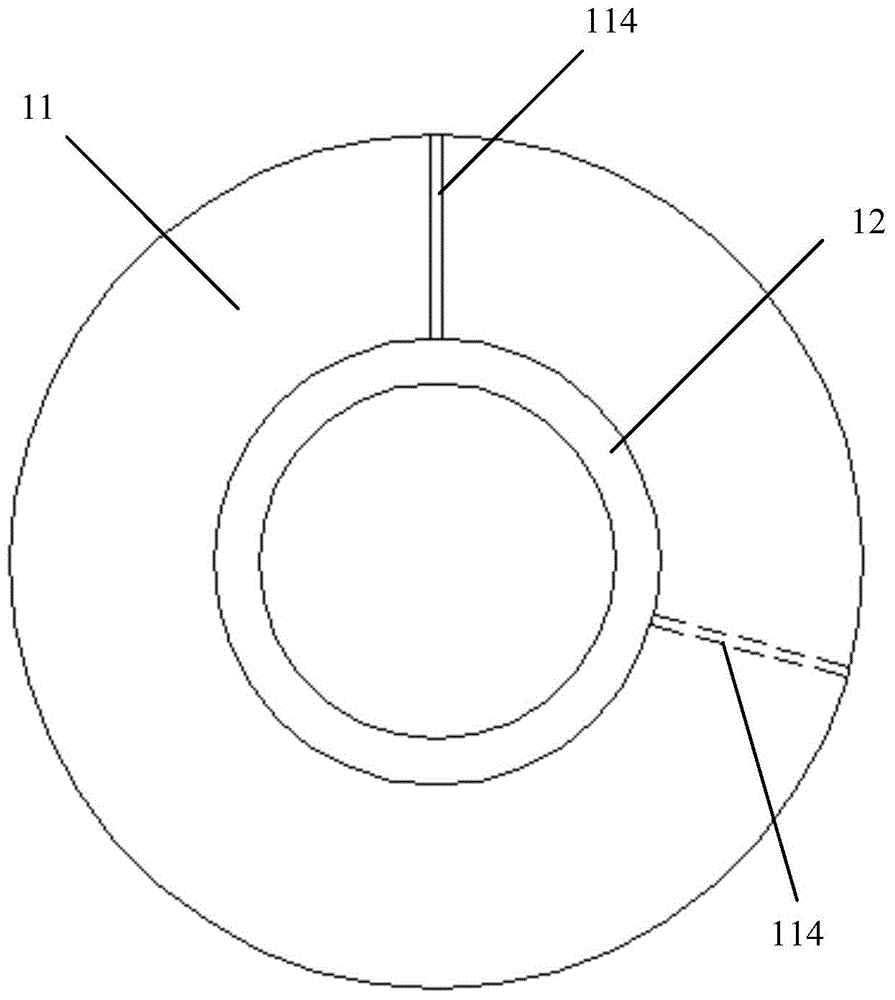

[0030] The embodiment of the present invention provides a bearing, such as figure 1 As shown, the bearing 1 includes a cylindrical outer sleeve 11 for connecting with the outer shaft tube (not shown) of the transmission shaft system and a circular cylindrical sleeve 11 for connecting with the major axis of the transmission shaft system (not shown). The cylindrical inner sleeve 12, the outer peripheral wall of the outer sleeve 11 is provided with a plurality of oil seepage annular grooves 112 arranged at intervals in the axial direction, and the inner peripheral wall of the outer sleeve 11 is provided with a ring for connecting the outer sleeve 11 and the inner sleeve. The clamping annular groove 111 of the shaft sleeve 12, the outer peripheral wall of the inner sleeve 12 is provided with a clamping protrusion 121 matched with the clamping annular groove 111, and the inner sleeve 12 is connected by the clamping protrusion 121 and the clamping The annular groove 111 is fixedly i...

Embodiment 2

[0040] The embodiment of the present invention provides a deep well pump drive shaft system, see image 3 , the transmission shaft system includes a long shaft 2, an outer shaft tube 3, and at least one bearing 1 provided by Embodiment 1, the long shaft 2 is rotatably coaxially inserted in the bearing 1, and the outer shaft tube 3 is sleeved on the bearing 1, the bearing 1 is sandwiched between the outer shaft tube 3 and the long shaft 2. The bearing 1 is arranged between the outer shaft tube 3 and the long shaft 2, which not only reduces the mechanical vibration of the transmission shaft, but also increases the structural stability of the transmission shaft, so that the upper limit of the length and the rigidity of the transmission shaft are improved.

[0041] In the embodiment of the present invention, the outer shaft tube 3 and the bearing 1 are in interference fit, because the outer shaft sleeve 11 of the bearing 1 is a fluorine rubber sleeve, so the elasticity between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com