A ccus system based on gas lift method and its application

A gas lift method and gas lift well technology, applied in the fields of fluid extraction, earthwork drilling, climate sustainability, etc., can solve problems such as increasing operating costs, failure of oil wells to inject thermal fluid without stopping production, and increased greenhouse gas emissions , to achieve the effects of saving production costs, benefiting environmental protection, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

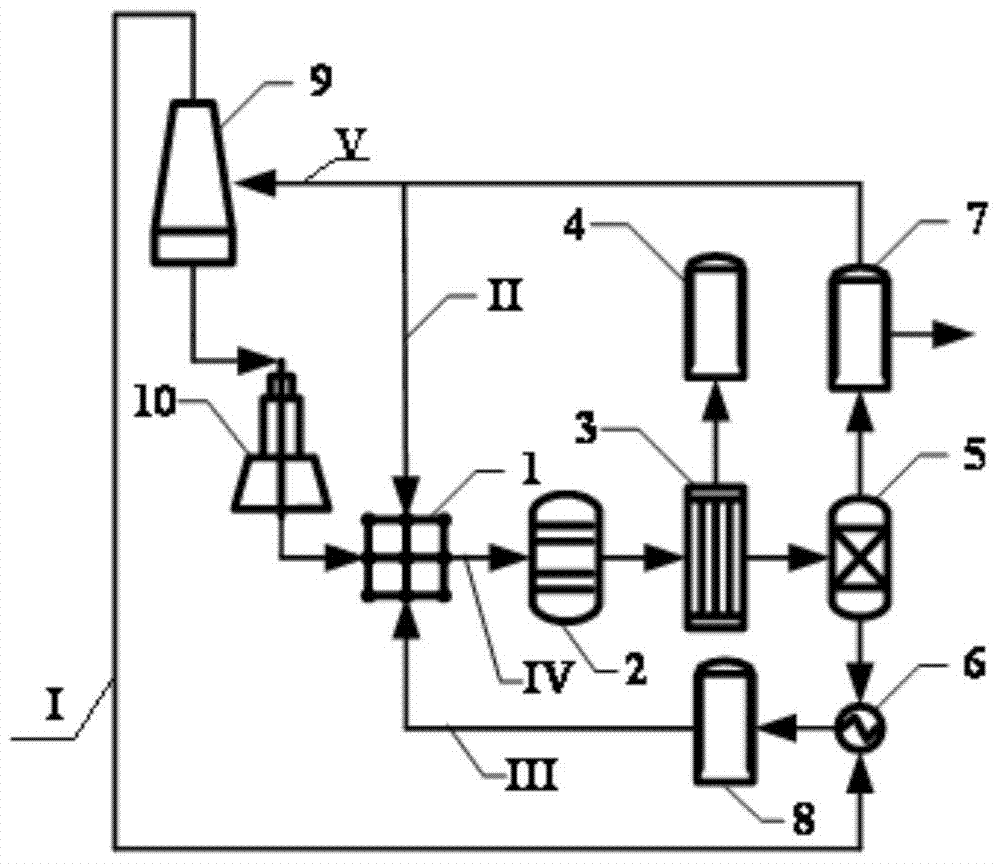

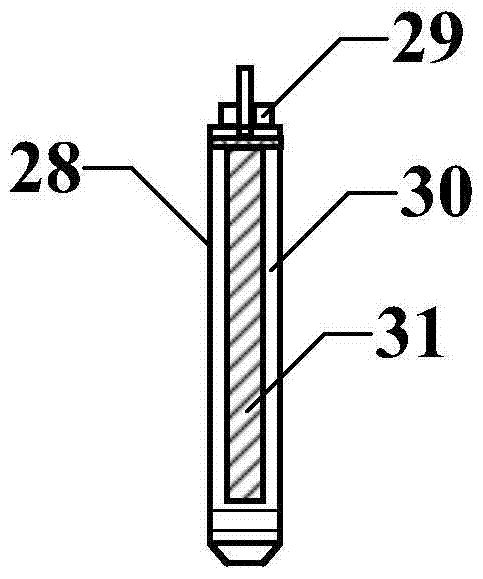

[0062] A CCUS system based on gas lift oil recovery, including production pipeline IV, carbon dioxide pipeline, natural gas pipeline, gas generator set 9 and electric heating wax removal and wax prevention device 10;

[0063] The production pipeline IV includes an oil-gas separation unit sequentially connected to the gas lift well group 1, a natural gas purification system 5, and a natural gas pipeline and a carbon dioxide pipeline respectively connected to the natural gas purification system 5;

[0064] The natural gas pipeline includes the natural gas pumping pipeline II for pumping natural gas into the gas lift well group 1, and also includes the natural gas transmission and power generation pipeline V for the gas-fired generator set 9 to generate electricity;

[0065] The carbon dioxide pipeline includes a carbon dioxide pumping pipeline III for pumping carbon dioxide into the gas lift well group 1, and also includes a carbon dioxide recovery pipeline I connected to the gas...

Embodiment 2

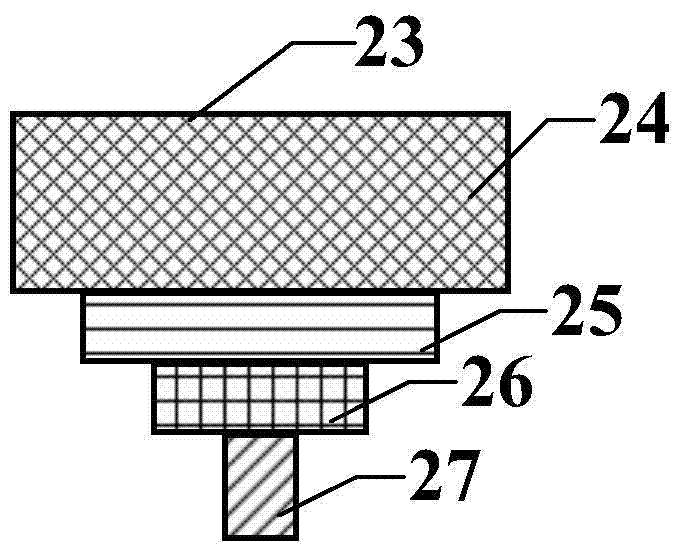

[0068] A CCUS system based on gas lift oil recovery as described in Embodiment 1, the difference is that the electric heating wax removal and anti-wax device 10 includes a steel armored cable 23 extending into the wellbore 22 through the sealing of the Christmas tree 19, so The steel armored cable 23 is powered by the gas generator set 9.

Embodiment 3

[0070] A kind of CCUS system based on gas lift oil recovery as described in Embodiment 2, the difference is that the steel armored cable 23 includes a steel armored sheath 24, an insulating material layer 25, a polytetrafluoro Vinyl layer 26 and cable core wire 27.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com