Display connection device for winding machine in carrier coil processing

A technology of connecting device and winding machine, applied in the direction of supporting machines, mechanical equipment, instruments, etc., can solve problems such as trouble, achieve the effects of convenient use, increase connection stability, and prevent surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

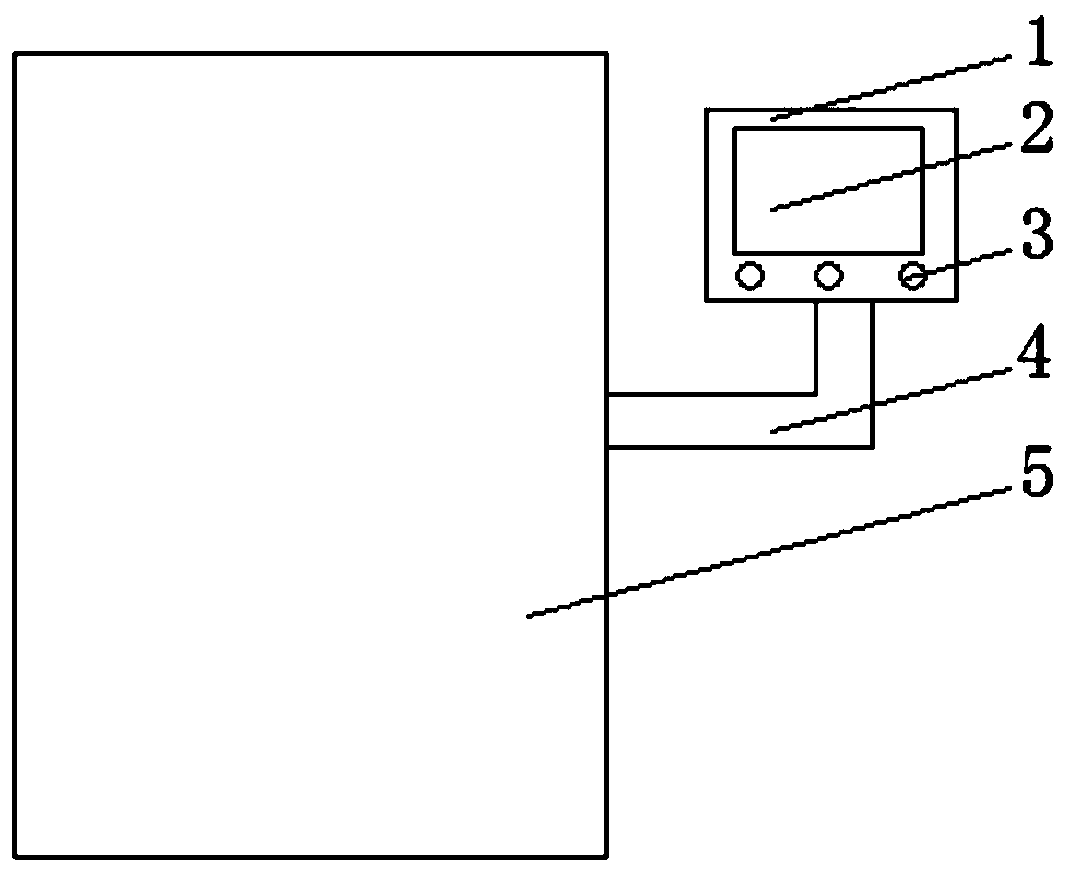

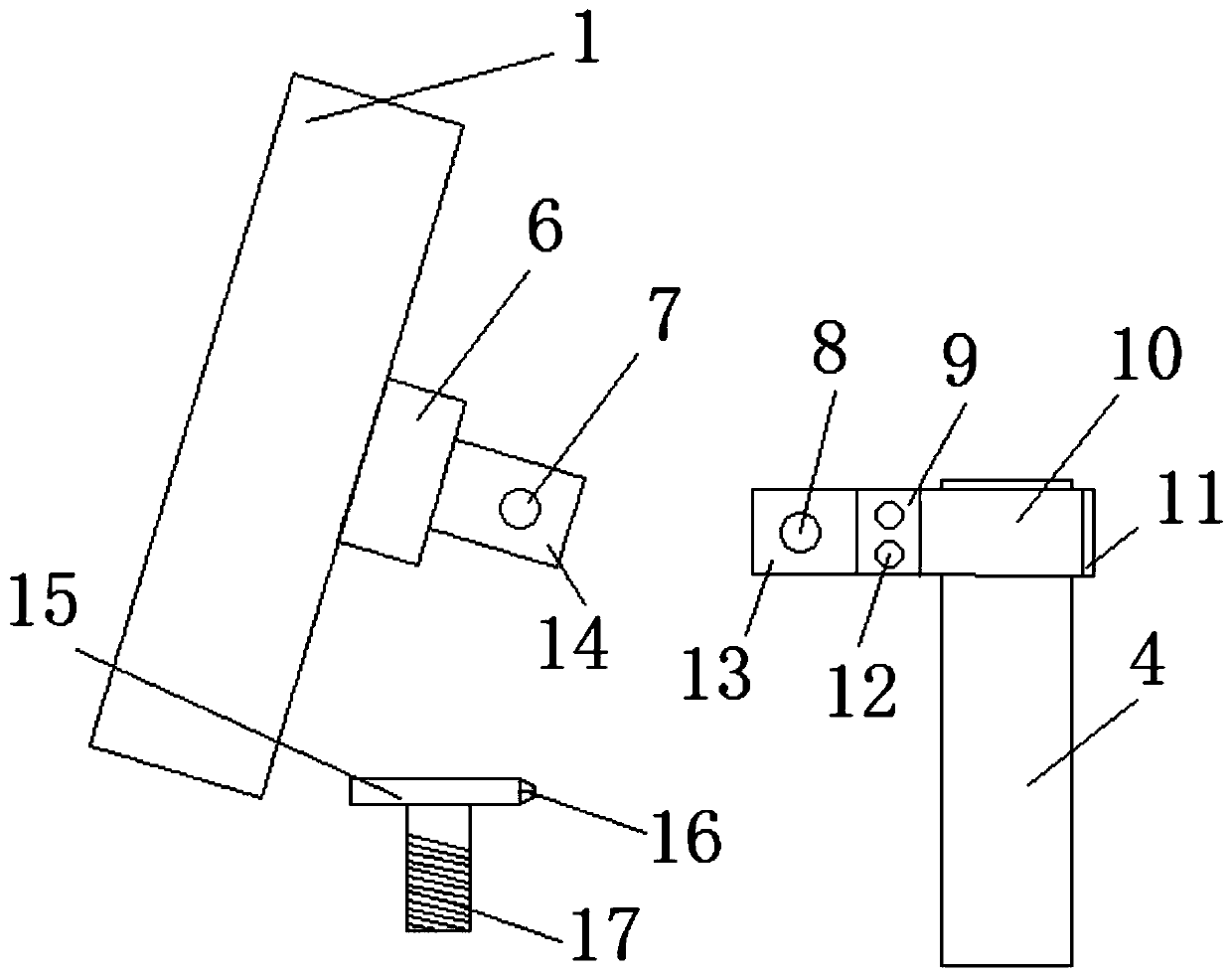

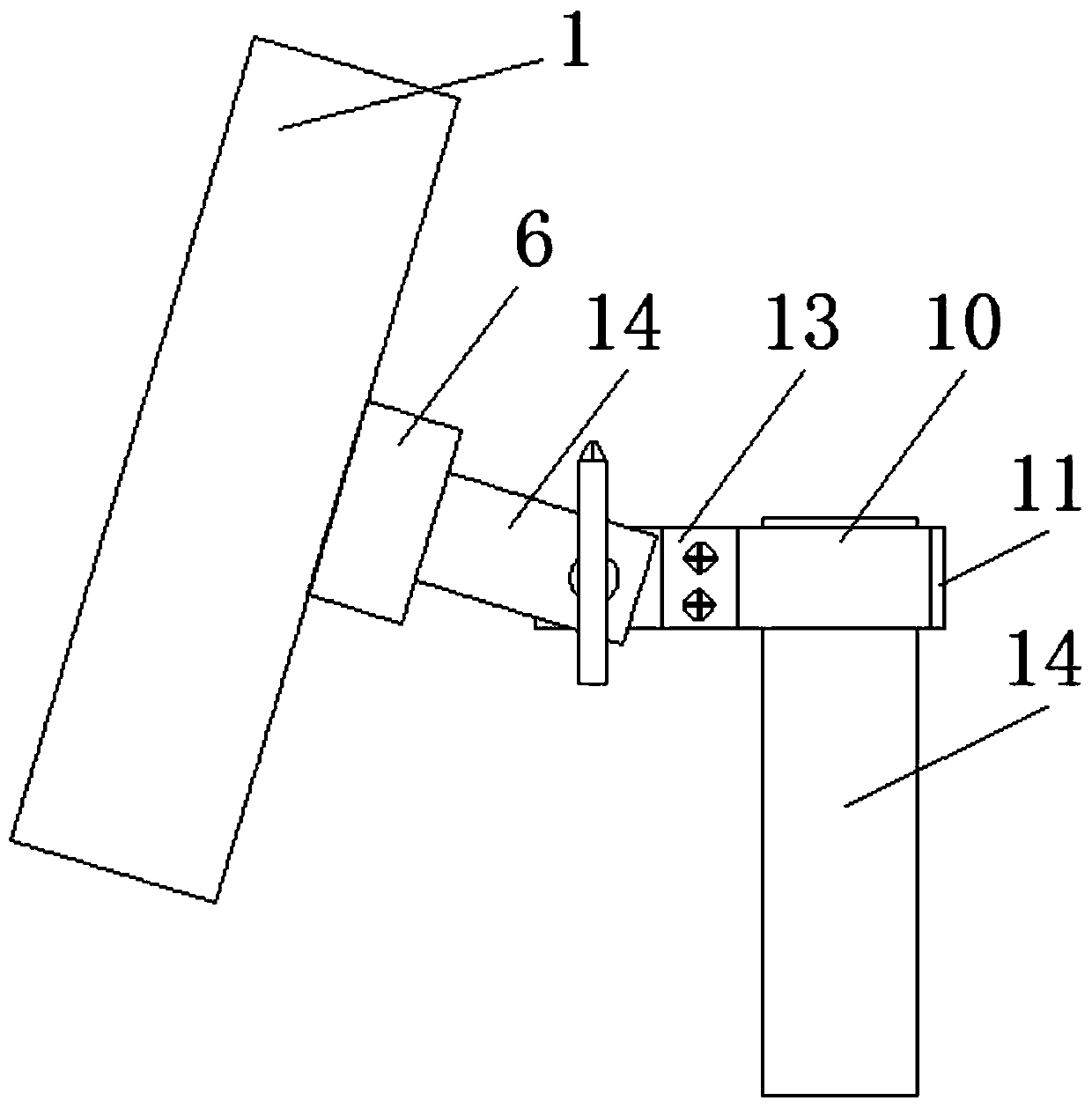

[0026] Embodiment 1, a display connection device for a winding machine in carrier coil processing, comprising a winding machine main body 5, a connecting rod 4, a display main body 1 and a display screen 2, and the winding machine main body 5 has a connection on one side Rod 4, the upper end of the connecting rod 4 is provided with a display main body 1, the front of the display main body 1 is provided with a display screen 2, and the display main body 1 at the bottom of the display screen 2 is provided with a number of evenly distributed adjustment buttons 3, so The central part of the back of the display main body 1 is provided with a fixing block 6, the fixing block 6 is provided with a fixing frame 14 vertically fixedly connected, and both ends of the fixing frame 14 are provided with symmetrically distributed first connecting threaded holes 7, so The fixing frame 14 is provided with a matching adjusting block 13, and the adjusting block 13 is provided with a second connecti...

Embodiment 2

[0030] In Example 2, the same parts as in Example 1 will not be repeated. The difference from Example 1 is that the non-slip rubber pad includes the following components by weight: 80 to 85 parts of natural rubber, 15 to 20 parts of styrene butadiene rubber Parts, modified bentonite 20-30 parts, vulcanization system 4-5 parts, activation system 6-7 parts, anti-aging system 6-10 parts, processing aid system 2-4 parts.

[0031] The vulcanization system includes the following components in parts by weight: 3.5 to 4 parts of insoluble sulfur IS-60, and 0.6 to 0.8 parts of accelerator CZ.

[0032] The activation system contains zinc oxide and stearic acid.

[0033] The anti-aging system includes anti-aging agent RD, anti-aging agent 4010NA, anti-aging agent 4020, anti-aging agent Rhein 654 microcrystalline wax, anti-aging agent HS-911, and anti-oxidant 1010.

[0034] The processing aid system includes processing aid L-24 and processing aid WB42.

Embodiment 3

[0035] In Example 3, the same points as in Example 2 will not be repeated. The difference from Example 2 is that the modification method of the modified bentonite is: adding bentonite to a hydrochloric acid solution containing 5% to 15%, And prepare a bentonite suspension with a mass fraction of 5% to 20%, place it in an ultrasonic generator, and ultrasonically react at a temperature of 50°C to 90°C for 5 hours to 20 hours. After the reaction is completed, rinse the slurry to a pH of 3 to In the range of 5, drying and grinding at about 50℃~110℃, sieving to obtain acidified bentonite from 80 mesh to 200 mesh; preparing a ferrous sulfate solution with a mass fraction of 5% to 30% and an aluminum sulfate solution with a mass fraction of 5% to 30%; According to the mass ratio of ferrous sulfate: aluminum sulfate: acidified bentonite=0.01~0.5:0.01~0.5:1, weigh the quantitative ferrous sulfate solution, aluminum sulfate solution and acidified bentonite; mix the quantitative acidified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com