Prefabricated walls for prefabricated buildings

A technology of prefabricated walls and buildings, applied in the direction of building structure, construction, building materials, etc., can solve the problems of construction speed, construction cost, energy consumption, complex assembly process, etc., to improve wall cracking, High component precision, reducing the effect of on-site construction and management personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

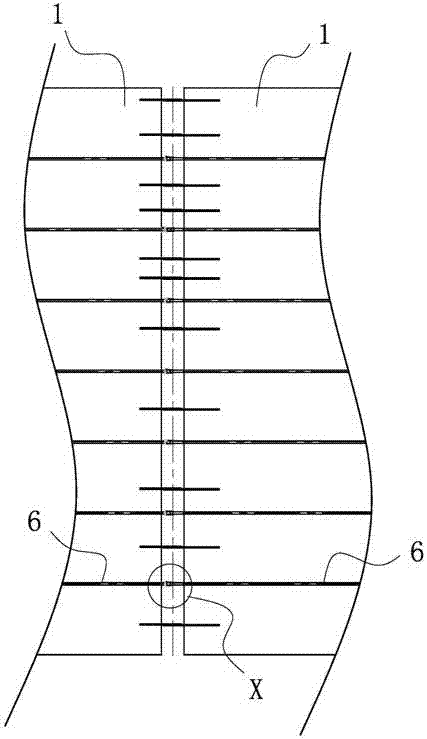

[0062] Such as Figure 1-34 As shown, the prefabricated wall body of this prefabricated building includes at least one prefabricated wall panel 1 made of reinforced concrete, and the described prefabricated wall panel 1 is provided with a number of cross bars 6 made of steel bars and extending transversely and some made of Longitudinal bars 8 made of steel bars and extending longitudinally. The upper end of the prefabricated wall panel 1 is provided with at least one lifting member A, and the lifting member A is detachably connected to the upper end of the longitudinal reinforcement 8 or prefabricated on the prefabricated wall panel 1 . The longitudinal ribs 8 between two adjacent prefabricated wall panels 1 up and down are provided in one-to-one correspondence and can be connected by a longitudinal rib connecting structure 9 .

[0063] In this example, if Figure 32-34 As shown, the longitudinal rib connection structure 9 includes a clamping sleeve 91 and a clamping joint 9...

Embodiment 2

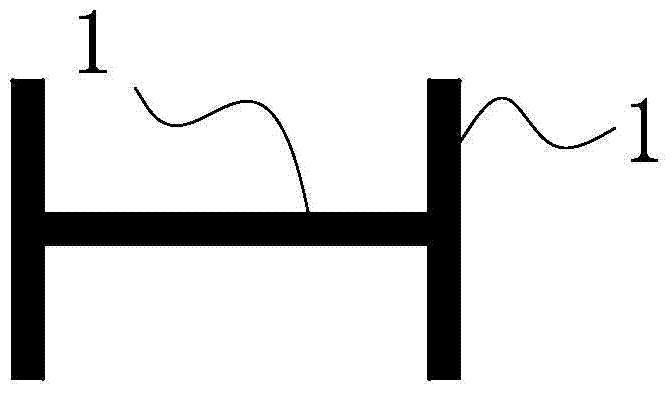

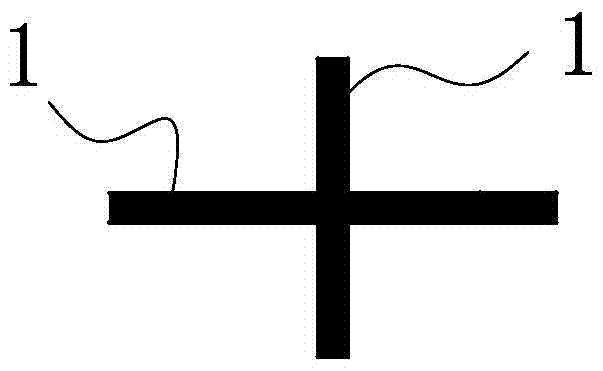

[0068] Such as Figure 2-25 As shown, each prefabricated wall panel 1 is connected into H-shaped wall body, cross-shaped body of wall, L-shaped body of wall, Yi-shaped body of wall, T-shaped body of wall, Z-shaped body of wall, F-shaped body of wall, U-shaped body of wall, Any one of D-shaped wall, I-shaped wall, one-shaped wall, Japanese-shaped wall, mountain-shaped wall, upper-shaped wall, well-shaped wall, rectangular wall, and rectangular wall with partial openings. Form the above-mentioned H-shaped wall, cross-shaped wall, L-shaped wall, Yi-shaped wall, T-shaped wall, Z-shaped wall, F-shaped wall, U-shaped wall, D-shaped wall, and I-shaped wall At least one of the prefabricated wall panels 1 of any one of wall body, one-shaped wall body, Japanese-shaped wall body, mountain-shaped wall body, upper-shaped wall body, well-shaped wall body, rectangular wall body, and rectangular wall body with partial openings One side of the prefabricated wall panel 1 has a concavo-convex s...

Embodiment 3

[0070] Such as Figure 26-29 As shown, the prefabricated wall also includes a prefabricated floor slab 3 made of reinforced concrete, a number of prefabricated wall panels 1 form a floor body 4 used as a single floor or a multi-storey floor, and the prefabricated floor slab 3 is arranged on the floor On the body 4, a single-layer floor body 41 or a multi-layer floor body 42 is formed. A floor 5 made of reinforced concrete is provided at the bottom of the single-story body 41 or the multi-layer body 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com