Thermal bimetal material

A technology of thermal bimetal and superalloy, applied in the field of metal materials, can solve the problems of low quality and high production cost, and achieve the effects of high quality, low production cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

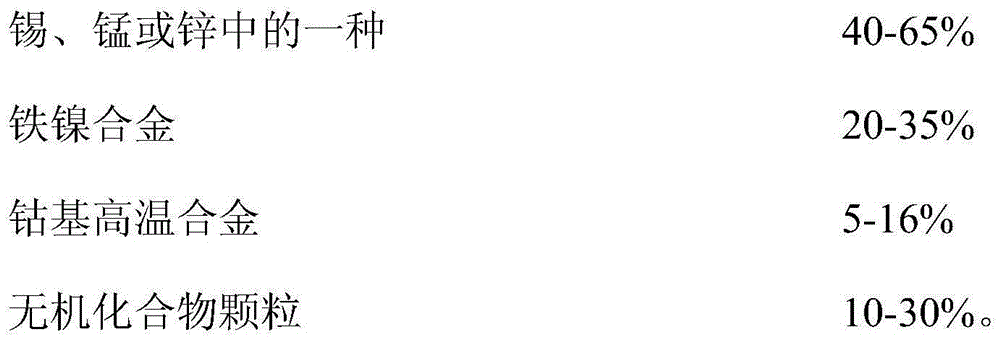

[0025] A thermal bimetallic material comprising the following components by weight percentage:

[0026]

[0027] Mix one of tin, manganese or zinc, iron-nickel alloy and cobalt-based superalloy in the formulated amount, melt it, cool it below the melting point of the inorganic compound particles, add the inorganic compound particles in the formulated amount, and mix evenly to obtain hot double metallic material.

Embodiment 2

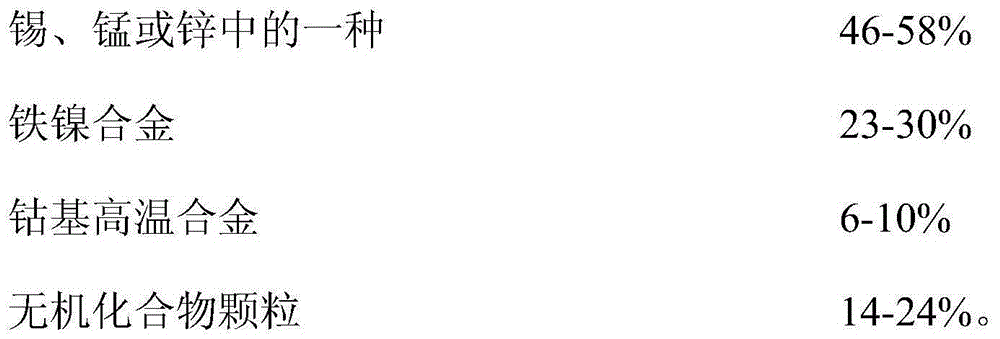

[0029] A thermal bimetallic material comprising the following components by weight percentage:

[0030]

[0031] The preparation method is the same as in Example 1.

Embodiment 3

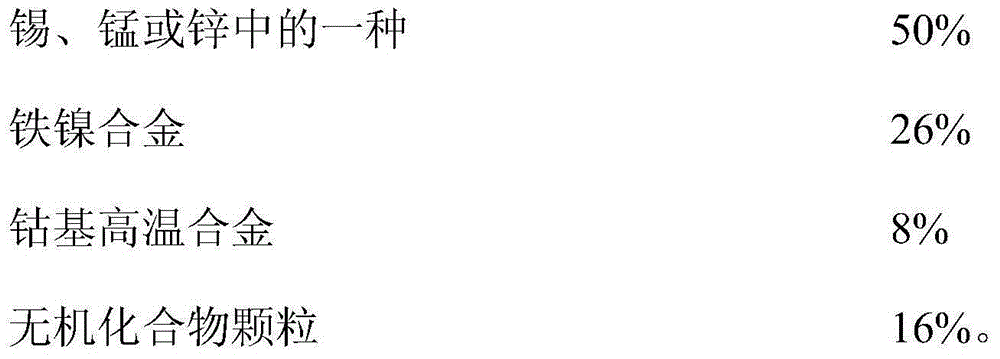

[0033] A thermal bimetallic material comprising the following components by weight percentage:

[0034]

[0035] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com