An organic solid waste composting device with double-layer material circulation and ventilation and a composting method using the device

A technology of organic solids and material circulation, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of low secondary fermentation efficiency, long composting cycle, and large floor area, so as to improve the efficiency of secondary fermentation , Increase nitrogen content, reduce the effect of odor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

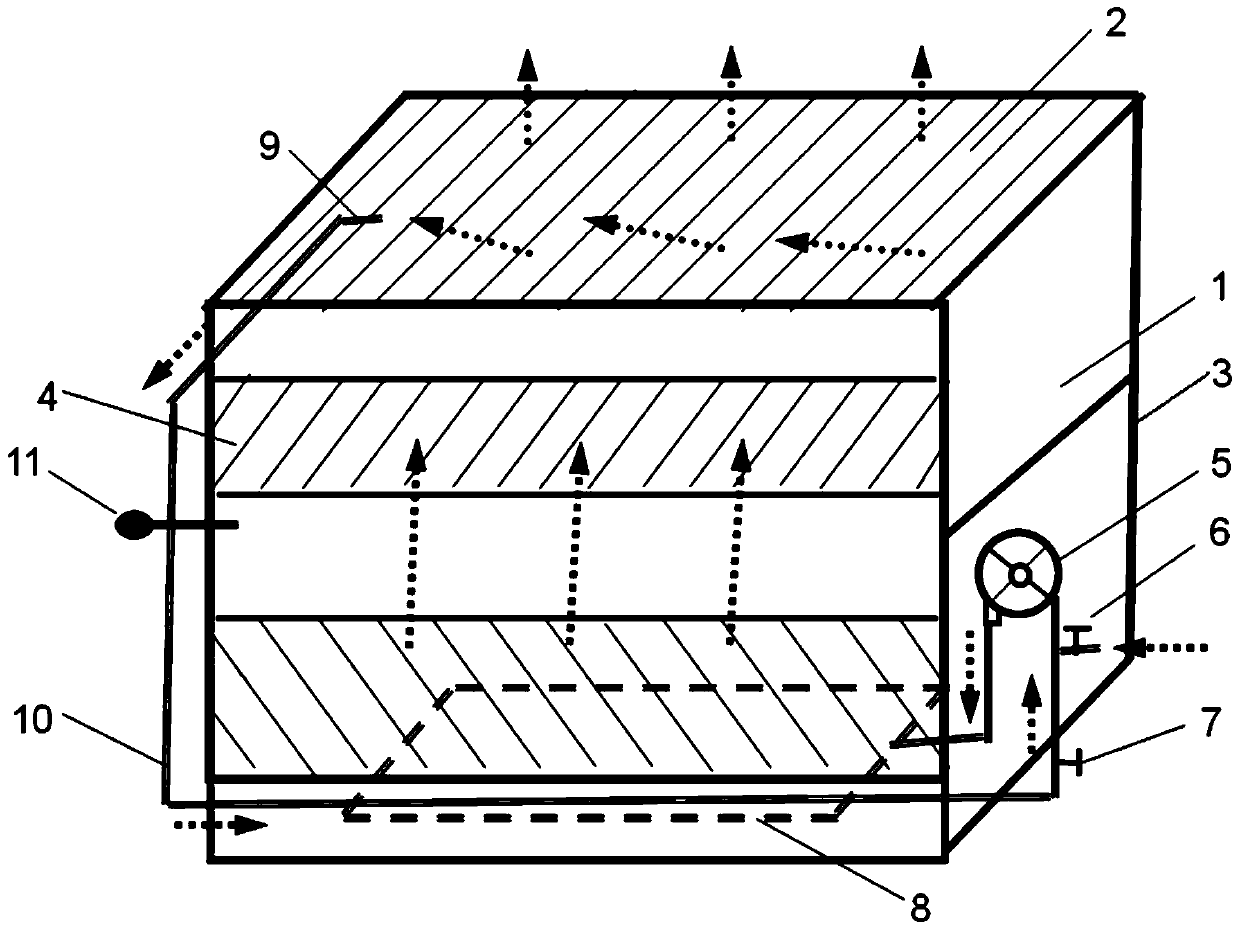

[0022] Specific implementation mode one: combine figure 1 As shown, the organic solid waste composting device with double-layer material circulation and ventilation in this embodiment includes a fermentation bin door 1, a fermentation bin 3, a fermentation bin cover 2, an annular perforated aeration pipe 8, a secondary fermentation tank 4, and a blower 5. Air intake valve 6, exhaust gas circulation valve 7, exhaust gas collection port 9, exhaust gas circulation pipe 10, temperature and oxygen concentration probe 11; a ring-shaped perforated aeration pipe 8 is arranged at the bottom of the fermentation chamber, and the exhaust gas circulation pipe 10 passes through the blower 5 Tail gas circulation valve 7 controls, secondary fermentation tank 4 is set in the middle of the fermentation bin, the secondary fermentation tank 4 adopts a porous plate or a screen, the temperature and oxygen concentration probe 11 is set under the secondary fermentation tank 4, and the top of the ferme...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is different from Embodiment 1 in that the side wall of the fermentation bin 3 is made of cement or metal plates. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that the depth of the secondary fermentation tank 4 is 30-300 cm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com