Moonlight white glaze and firing method thereof

A technology of white glaze and moonlight, which is applied in the field of moonlight white glaze and its firing, can solve the problems of insufficient ornamental quality, aesthetic fatigue, single glaze color, etc., and achieve bright and smooth glaze lines, strong glaze texture, The effect of the glaze color feature is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

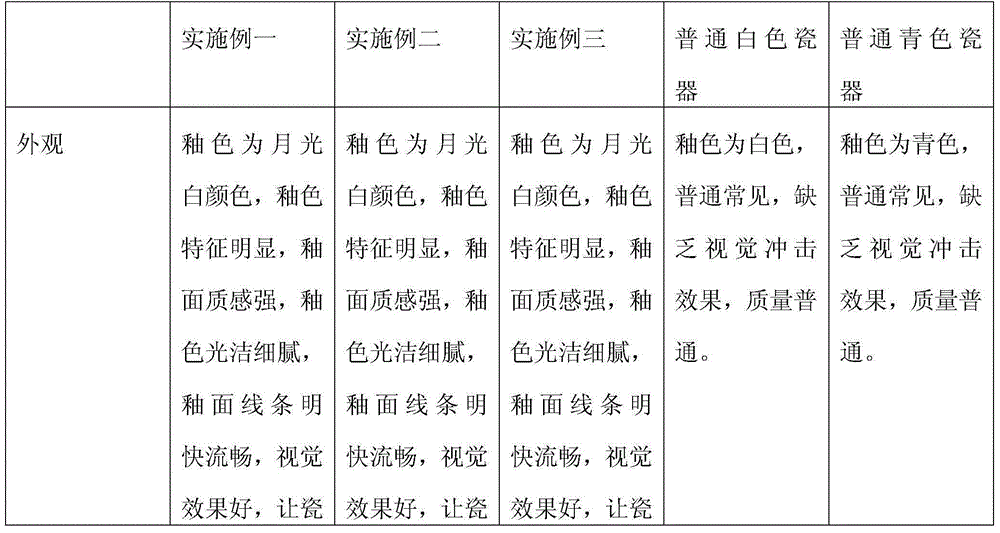

Embodiment 1

[0016] The moonlight white glaze is made of the following raw materials in parts by weight: 50 parts of glaze soil, 5 parts of quartz, 18 parts of limestone, 10 parts of feldspar, 10 parts of talc, and 5 parts of glaze fruit.

[0017] The firing method of the above moonlight white glaze is:

[0018] In the first step, mixing, uniformly mixing the selected glaze soil, quartz, limestone, feldspar, talc, and glaze fruit, wet ball milling for 10 hours, and then pass the ball-milled glaze through a 180-mesh sieve to obtain the glaze;

[0019] The second step is to apply the glaze. The obtained glaze is mixed with water to prepare a glaze slurry of 66 Baume, then the porcelain embryo is taken, and the ceramic embryo is glazed by the glaze dip method. After the glaze is applied, it is placed in a cool and ventilated place for natural air drying and drying. Time is 8 hours;

[0020] The third step is smelting. Put the dried raw material into the kiln for firing. During firing, the temperature...

Embodiment 2

[0022] The moonlight white glaze is made of the following raw materials in parts by weight: 70 parts of glaze soil, 8 parts of quartz, 22 parts of limestone, 20 parts of feldspar, 20 parts of talc, and 7 parts of glaze fruit.

[0023] The firing method of the above moonlight white glaze is:

[0024] In the first step, mixing, uniformly mixing the selected glaze soil, quartz, limestone, feldspar, talc, and glaze fruit, wet ball milling for 11 hours, and then pass the ball milled glaze through a 190 mesh sieve to obtain the glaze;

[0025] The second step is to apply the glaze. The obtained glaze is mixed with water to make a 68 Baume glaze slurry, and then the porcelain embryo is taken, and the original embryo is glazed by the glaze dip method. After the glaze is applied, it is placed in a cool and ventilated place for natural air drying and drying. Time is 9 hours;

[0026] The third step is smelting. Put the dried raw material into a kiln for firing. During firing, the temperature of...

Embodiment 3

[0028] The moonlight white glaze is made of the following raw materials in parts by weight: 80 parts of glaze soil, 10 parts of quartz, 25 parts of limestone, 30 parts of feldspar, 30 parts of talc, and 10 parts of glaze fruit.

[0029] The firing method of the above moonlight white glaze is:

[0030] In the first step, mixing, uniformly mixing the selected glaze soil, quartz, limestone, feldspar, talc, and glaze fruit, wet ball milling for 12 hours, and then pass the ball-milled glaze through a 200-mesh sieve to obtain the glaze;

[0031] The second step is to apply the glaze. The obtained glaze is mixed with water to prepare a 72 Baume glaze slurry, and then the porcelain embryo is taken, and the glaze is applied to the embryo by the glaze dip method. After the glaze is applied, it is placed in a cool and ventilated place for natural air drying and drying. The time is 10 hours;

[0032] The third step is smelting. Put the dried raw material into the kiln for firing. During firing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com